Spraying elastic methacrylate coating

A technology of methacrylate and methyl methacrylate, applied in the field of spray-type elastic methyl methacrylate coatings, can solve the problems of high requirements for spraying equipment, limited application of sprayed polyurea, unsuitable construction, etc., so as to shorten the construction period. The effect of excellent time and weather resistance, and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

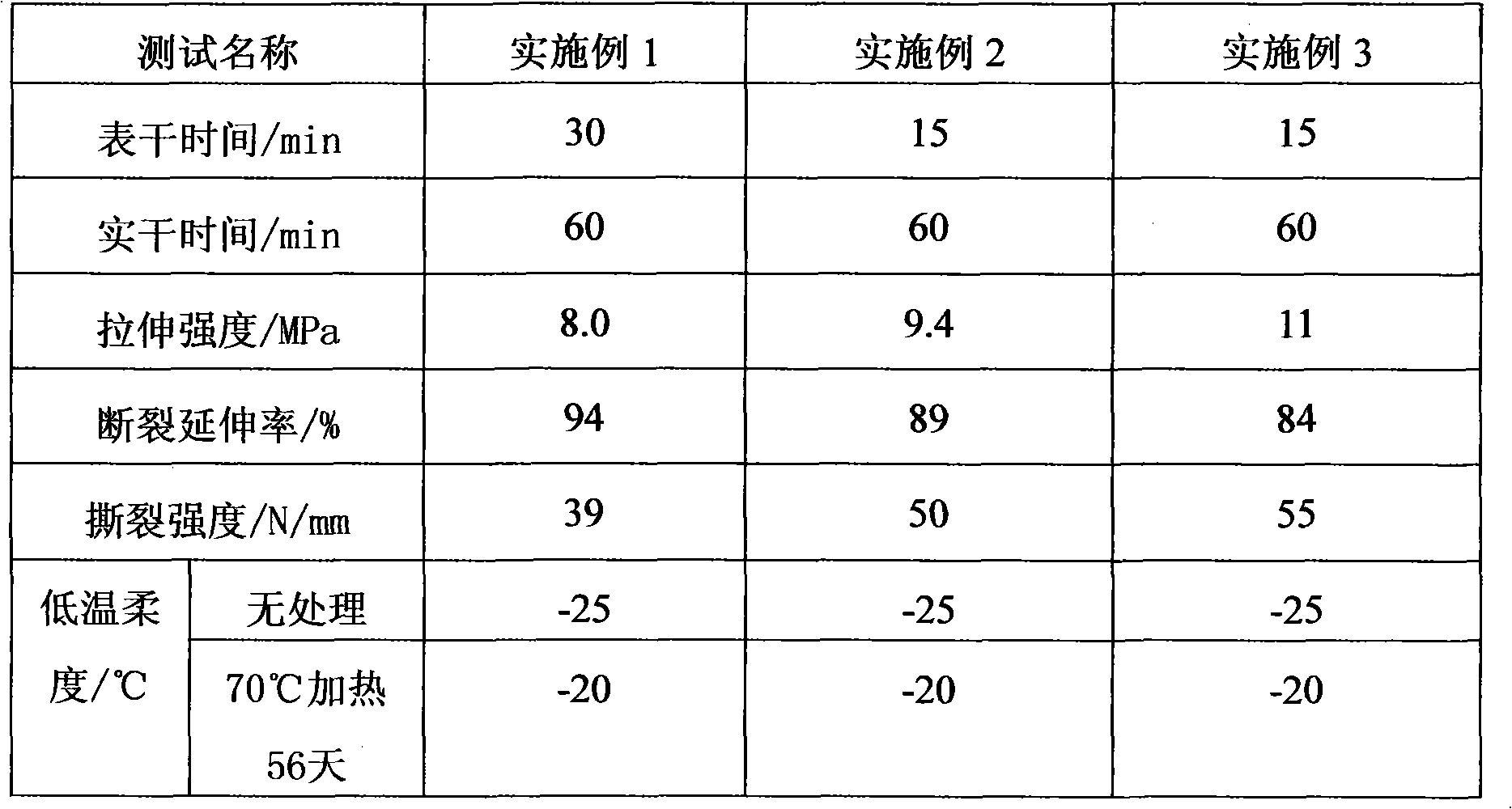

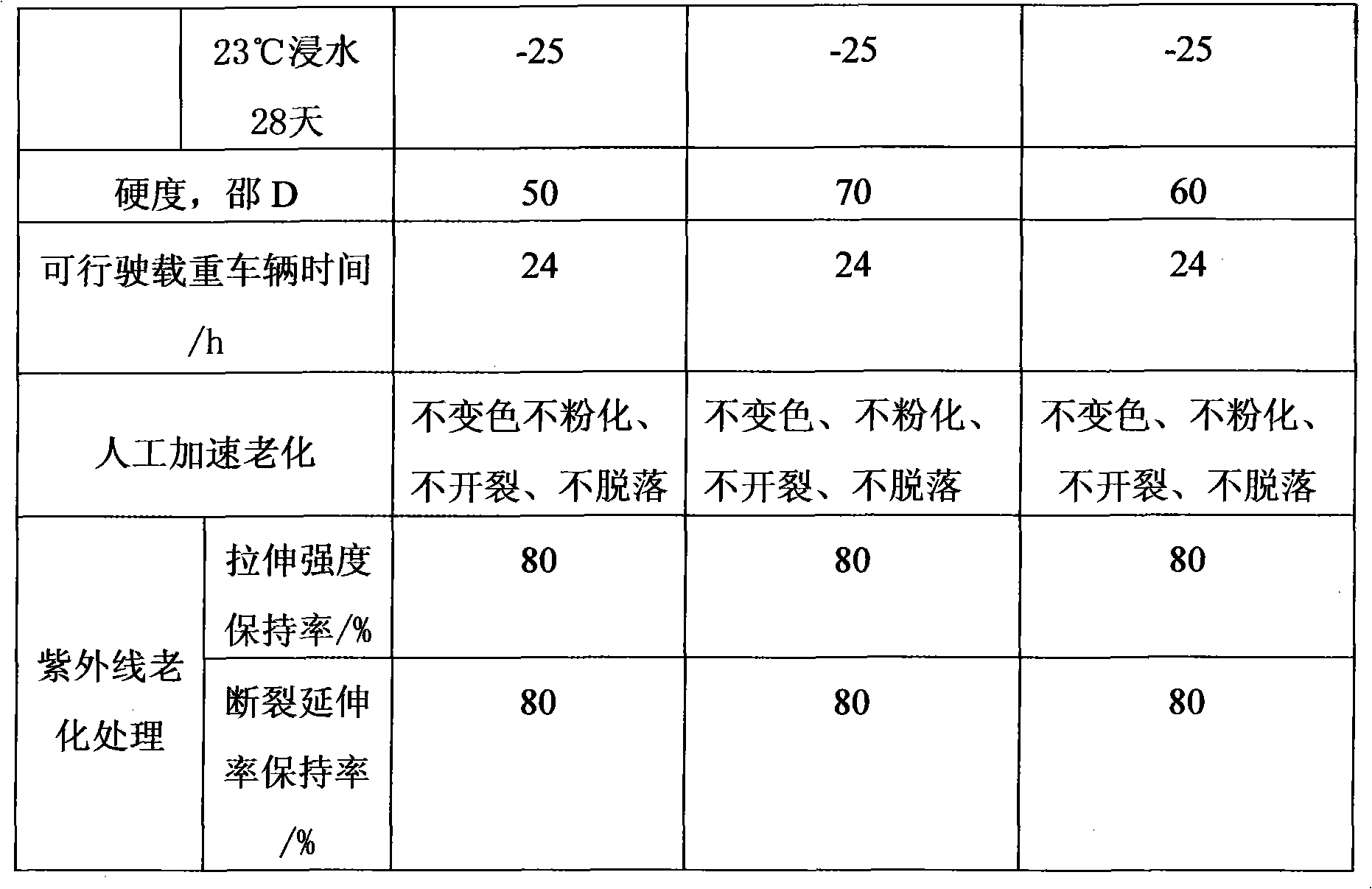

Embodiment 1

[0024] Mix 0.7 parts of paraffin, 70 parts of MMA, 10 parts of butyl acrylate, 30 parts of polyurethane acrylic acid prepolymer, and 10 parts of titanium dioxide, and then divide them into two equal parts, and add 1 part of N, N-dimethyl Aniline mixed evenly is the B component, and the other part is the A component. Add 2 parts of C component containing benzoyl peroxide to A component, and mix evenly with the American Graco high-pressure airless sprayer ULTRA395 spray gun to obtain A+C, and combine A+C and B into two groups After metering, heating and pressurizing in the airless spraying equipment with a fixed ratio of 1:1, it is mixed evenly through the spray gun and then sprayed on the substrate, and then cured to obtain elastic MMA coating.

Embodiment 2

[0026] Mix 1 part of paraffin, 50 parts of MMA, 10 parts of butyl acrylate, 50 parts of polyurethane acrylic prepolymer, and 10 parts of titanium dioxide, and then divide it into two equal parts, and add 1 part of N, N-dimethyl P-toluidine mixed evenly is the B component, and the other part is the A component. Add 2 parts of C component containing benzoyl peroxide to A component, and mix evenly with the American Graco high-pressure airless sprayer ULTRA395 spray gun to obtain A+C, and combine A+C and B into two groups After being metered, heated and pressurized in an airless spraying equipment with a fixed ratio of 1:1, it is mixed evenly through a spray gun and then sprayed on the substrate, and then cured to obtain an elastic MMA coating.

Embodiment 3

[0028] Mix 1 part of paraffin, 50 parts of MMA, 20 parts of isooctyl acrylate, 30 parts of polyurethane acrylic acid prepolymer, and 10 parts of carbon black, and then divide it into two equal parts, and add 1 part of N, N-dimethyl The base-p-toluidine is mixed evenly, which is the B component, and the other part is the A component. Add 2 parts of C component containing benzoyl peroxide to A component, and mix evenly with the American Graco high-pressure airless sprayer ULTRA395 spray gun to obtain A+C, and combine A+C and B into two groups After being metered, heated and pressurized in an airless spraying equipment with a fixed ratio of 1:1, it is mixed evenly through a spray gun and then sprayed on the substrate, and then cured to obtain an elastic MMA coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com