Adhesive composition and adhesive sheet

A composition and adhesive technology, applied in the direction of adhesives, non-polymer organic compound adhesives, adhesive types, etc., can solve problems such as inability to achieve, and achieve the effect of excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

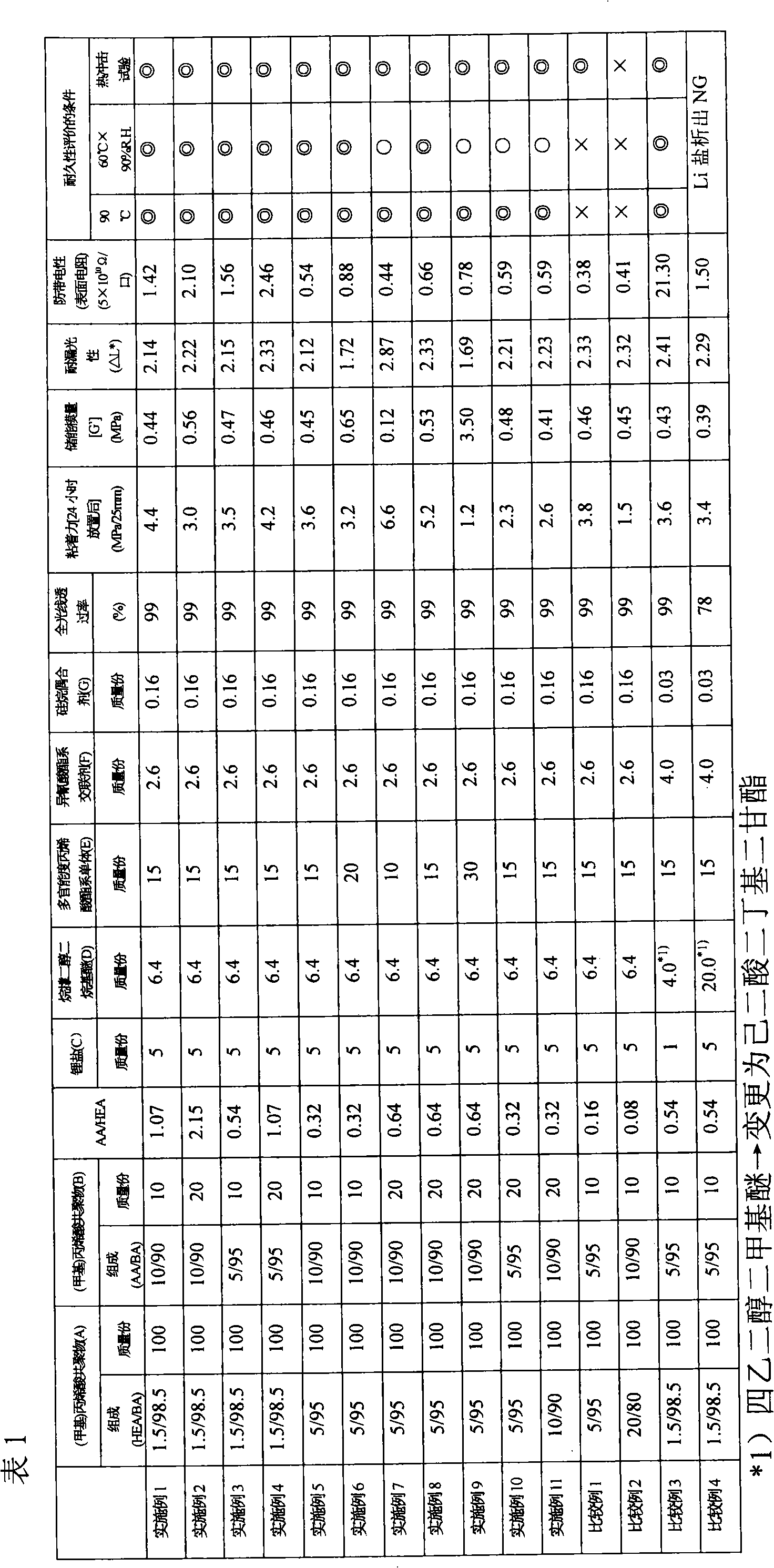

[0105] and

[0106] Adhesive compositions having blend compositions (in terms of solid content) shown in Table 1 were prepared, and samples were prepared according to the following processing procedures.

[0107] Next, the adhesive composition [diluted by adding toluene to a solid content of 20% by mass] was coated on a release film made of polyethylene terephthalate and having a thickness of 38 μm [manufactured by Lintec Corporation, " SP-PET3811” on the release layer so that the thickness after drying is 25 μm. The drying temperature was 90° C., and the drying time was 1 minute.

[0108] Thereafter, the polarizing plate with the discotic liquid crystal layer (viewing angle widening functional layer) was bonded so that the adhesive was in contact with the discotic liquid crystal layer. UV irradiation was performed from the side of the release film within 1 hour from the start of bonding to obtain a sample of a polarizing plate with an adhesive layer (hereinafter, simply r...

Embodiment 12

[0158] An adhesive composition having a blend composition (in terms of solid content) shown in Example 1 of Table 1 was prepared, and the adhesive composition [diluted with toluene to 20% by mass of solid content] was coated on the A peeling film made of polyethylene terephthalate and having a thickness of 38 µm [manufactured by Lintec, "SP-PET3811"] was placed on the peeling layer so that the thickness after drying was 25 µm. The drying temperature was 90° C., and the drying time was 1 minute.

[0159] Thereafter, lamination was performed so that the peeling layer of a peeling film made of polyethylene terephthalate and having a thickness of 38 μm [manufactured by Lintec, "SP-PET3811"] was in contact with the exposed surface of the layer obtained by the above-mentioned process.

[0160] Next, an adhesive sheet having a release film on both surfaces of the adhesive layer was obtained by irradiating the side of the release film ["SP-PET3801" manufactured by Lintec Co., Ltd., "S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com