Nutrient film protecting agent of rhizobium japonicum and production method thereof

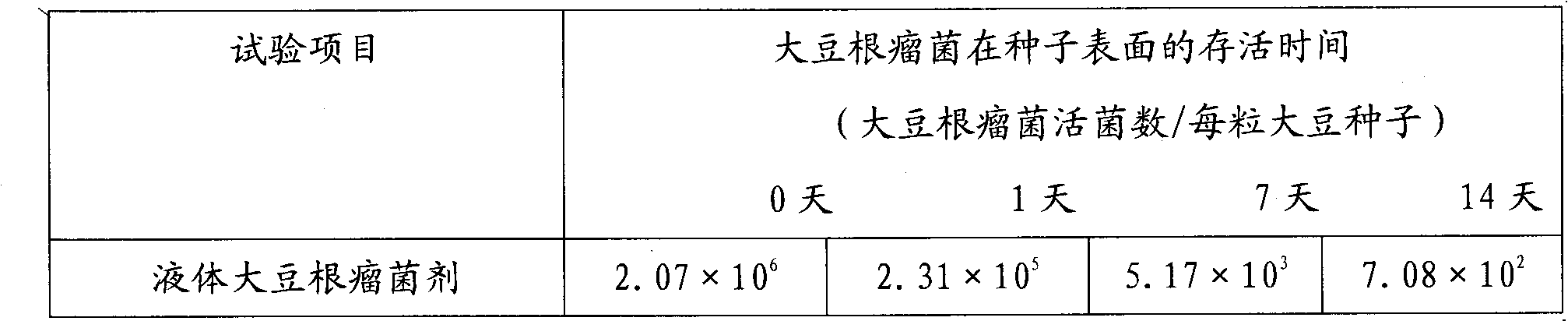

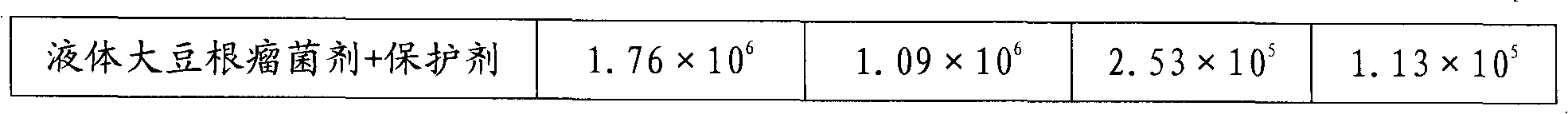

A soybean rhizobia and production method technology are applied in the fields of agricultural microorganisms and biochemical industries, can solve the problems of inability to realize commercial production and application, inability to apply in large areas, attenuation of viable bacterial counts, etc., and achieve good field application effect and soybean root nodules The effect of high bacterial count and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] First, sodium methylcellulose, polyvinylpyrrolidone PVPK30 and polyvinylpyrrolidone PVP S630 were slowly stirred and dissolved in purified water respectively, and then the three were mixed together, then peptone, bovine serum albumin and sodium molybdate were added, at a certain Make it slowly dissolve and react under reaction conditions; the described parts by weight are contained in every 100 parts of soybean rhizobia nutrient film protective agent: polyvinylpyrrolidone PVPK30 is 1 part, polyvinylpyrrolidone PVPS630 is 1 part, 0.2 part of sodium methylcellulose, 5 parts of peptone, 0.01 part of bovine serum albumin, 0.1 part of sodium molybdate, and the rest are pure water; the reaction conditions are: the pH of the solution is 6.8, and the aeration ratio is 1 : 0.6, the temperature is 25° C. and the time is 50 hours, and the reaction vessel is a fermenter. The liquid is red in color, non-toxic and has a clear fragrance.

Embodiment 2

[0019] First, sodium methylcellulose, polyvinylpyrrolidone PVPK30 and polyvinylpyrrolidone PVP S630 were slowly stirred and dissolved in purified water respectively, and then the three were mixed together, then peptone, bovine serum albumin and sodium molybdate were added, at a certain Make it slowly dissolve and react under reaction conditions; the described parts by weight are contained in every 100 parts of soybean rhizobium nutrient film protective agent: 5 parts of polyvinylpyrrolidone PVPK30, 5 parts of polyvinylpyrrolidone PVPS630, 1 part of sodium methylcellulose, 10 parts of peptone, 0.1 part of bovine serum albumin, 0.3 part of sodium molybdate, and the rest are pure water; the reaction conditions are: the pH of the solution is 7.0, and the aeration ratio is 1 : 0.7, the temperature is 27° C. and the time is 55 hours, and the reaction vessel is a fermenter. The liquid is red in color, non-toxic and has a clear fragrance.

Embodiment 3

[0021] First, sodium methylcellulose, polyvinylpyrrolidone PVPK30 and polyvinylpyrrolidone PVP S630 were slowly stirred and dissolved in purified water respectively, and then the three were mixed together, then peptone, bovine serum albumin and sodium molybdate were added, at a certain Make it slowly dissolve and react under reaction conditions; the described parts by weight are contained in every 100 parts of soybean rhizobia nutrient film protective agent: 10 parts of polyvinylpyrrolidone PVPK30, 10 parts of polyvinylpyrrolidone PVPS630, 2 parts of sodium methylcellulose, 20 parts of peptone, 0.2 parts of bovine serum albumin, 0.5 parts of sodium molybdate, and the rest are pure water; the reaction conditions are: the pH of the solution is 7.2, and the aeration ratio is 1 : 0.8, the temperature is 30° C. and the time is 60 hours, and the reaction vessel is a fermenter. The liquid is red in color, non-toxic and has a clear fragrance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com