Reflective material, reflective membrane, reflective board and preparation method thereof

A reflective material and reflective film technology, applied in the field of optical materials, can solve the problems of loss of reflective ability, oxidative deterioration, peeling, etc., and achieve the effects of easy mass production, enhanced bending resistance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of a kind of reflective material provided by the present invention comprises: 30~50wt% barium sulfate powder, 5~8wt% titanium dioxide, 5~10wt% pearl powder, 10~20wt% film-forming aid, the rest It is an organic solvent, and it forms an organic fusion after thorough mixing.

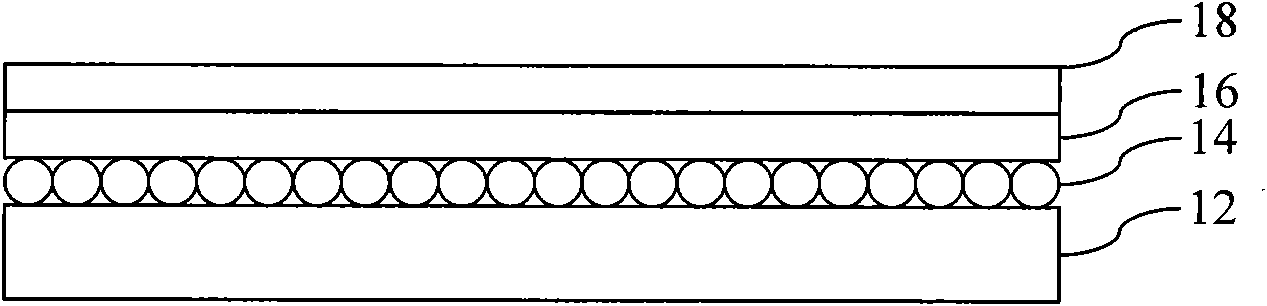

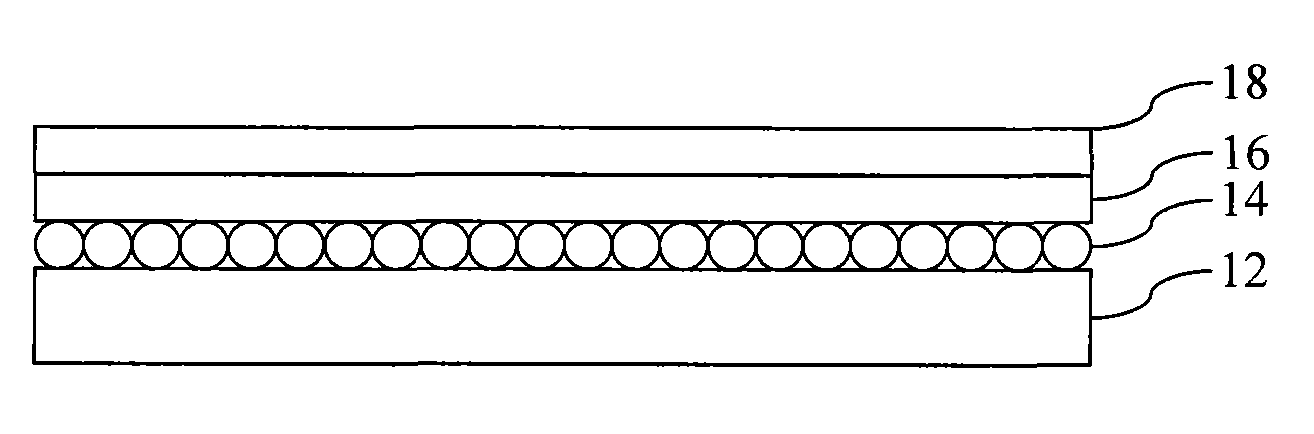

[0024] A kind of reflective film provided by the invention, such as figure 1 As shown, it includes a substrate 12, the substrate 12 is coated with the above-mentioned reflective material coating 14, the reflective material coating is coated with an ultraviolet absorber, and the ultraviolet absorber coating 16 is coated with It has a transparent protective film 18 .

[0025] The reflective film can be applied to the reflective surface of the reflective plate of the lighting device. Accordingly, the present invention also provides a reflective plate for a lighting device, comprising a substrate, and the reflective film as described above is provided on the surface of the substr...

Embodiment 1

[0036] 30wt% of barium sulfate powder, 5wt% of titanium dioxide, 5wt% of pearl powder, 10wt% of film-forming aids, and the rest are organic solvents, mixed at room temperature, and fully stirred to form an organic fusion.

[0037] This reflective material is coated on the substrate, and then coated with an ultraviolet absorber UV coating, and then a transparent protective layer is formed by thermocompression on the outermost layer, thus forming a reflective film, which is applied to lighting The reflection efficiency of the reflector of the device can reach about 90%. However, the reflection efficiency of ordinary aluminum is only more than 80%, and the price is expensive.

Embodiment 2

[0039] 40wt% of barium sulfate powder, 7wt% of titanium dioxide, 8wt% of pearl powder, 15wt% of film-forming aid, and the rest are organic solvents, mixed at room temperature, and fully stirred to form an organic fusion.

[0040] The reflection efficiency of the reflective plate formed by the reflective material can reach about 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com