Metal substrate and light-emitting diode encapsulation method of metal substrate

A technology of metal substrate and packaging method, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of low light extraction efficiency, poor heat dissipation, and poor light color performance of white light, so as to reduce production costs and reduce new interfaces. Spawn chance, remove the effect of the air interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

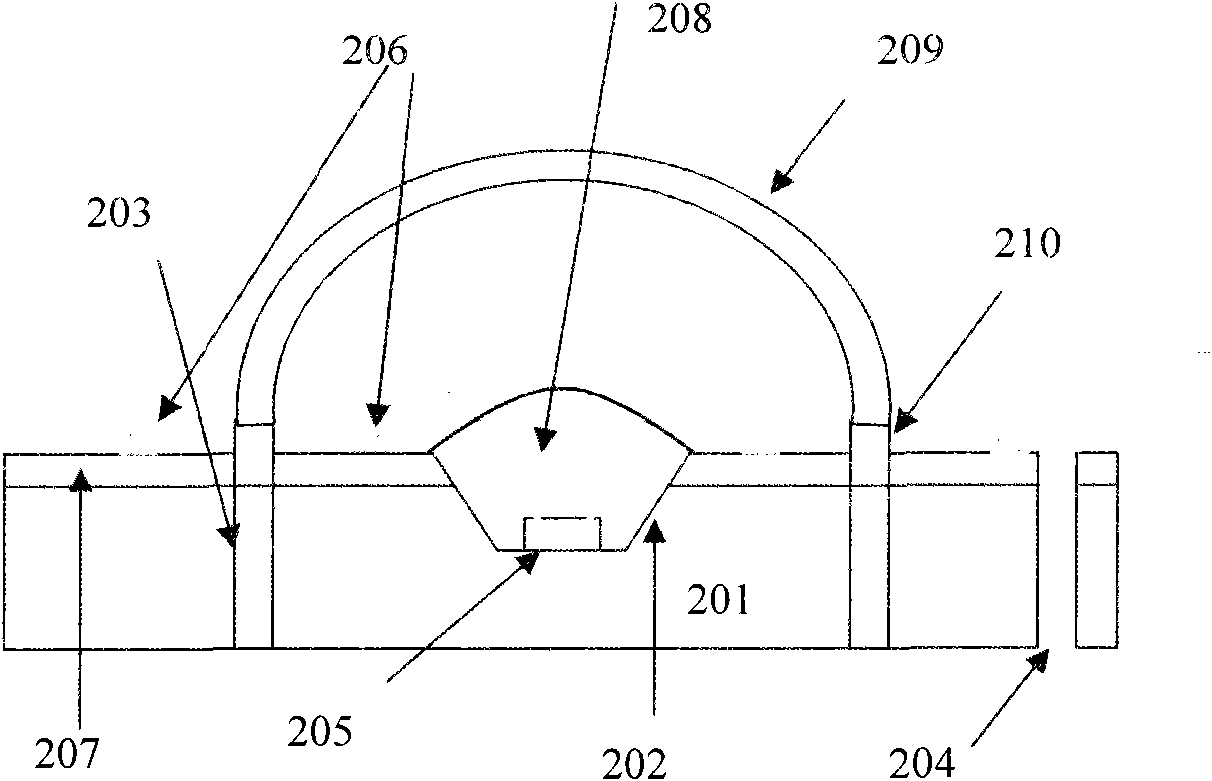

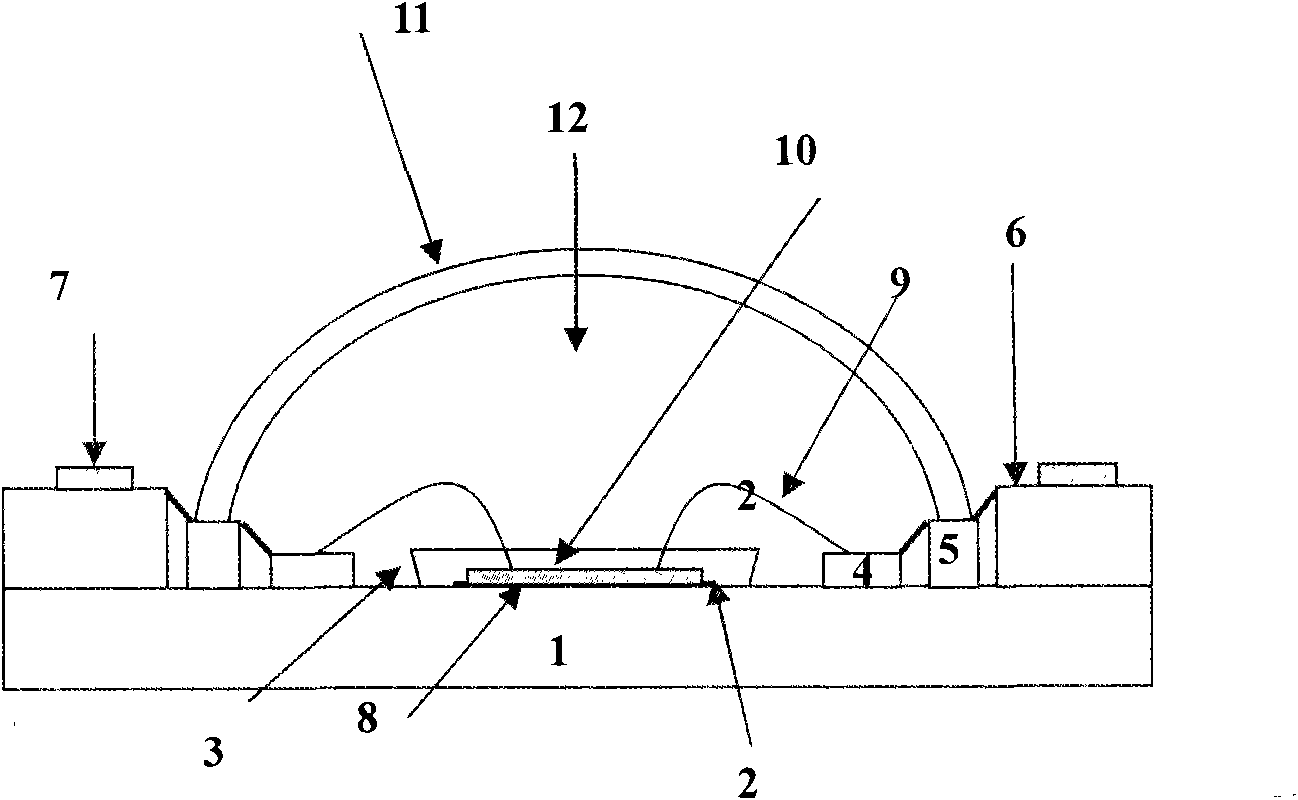

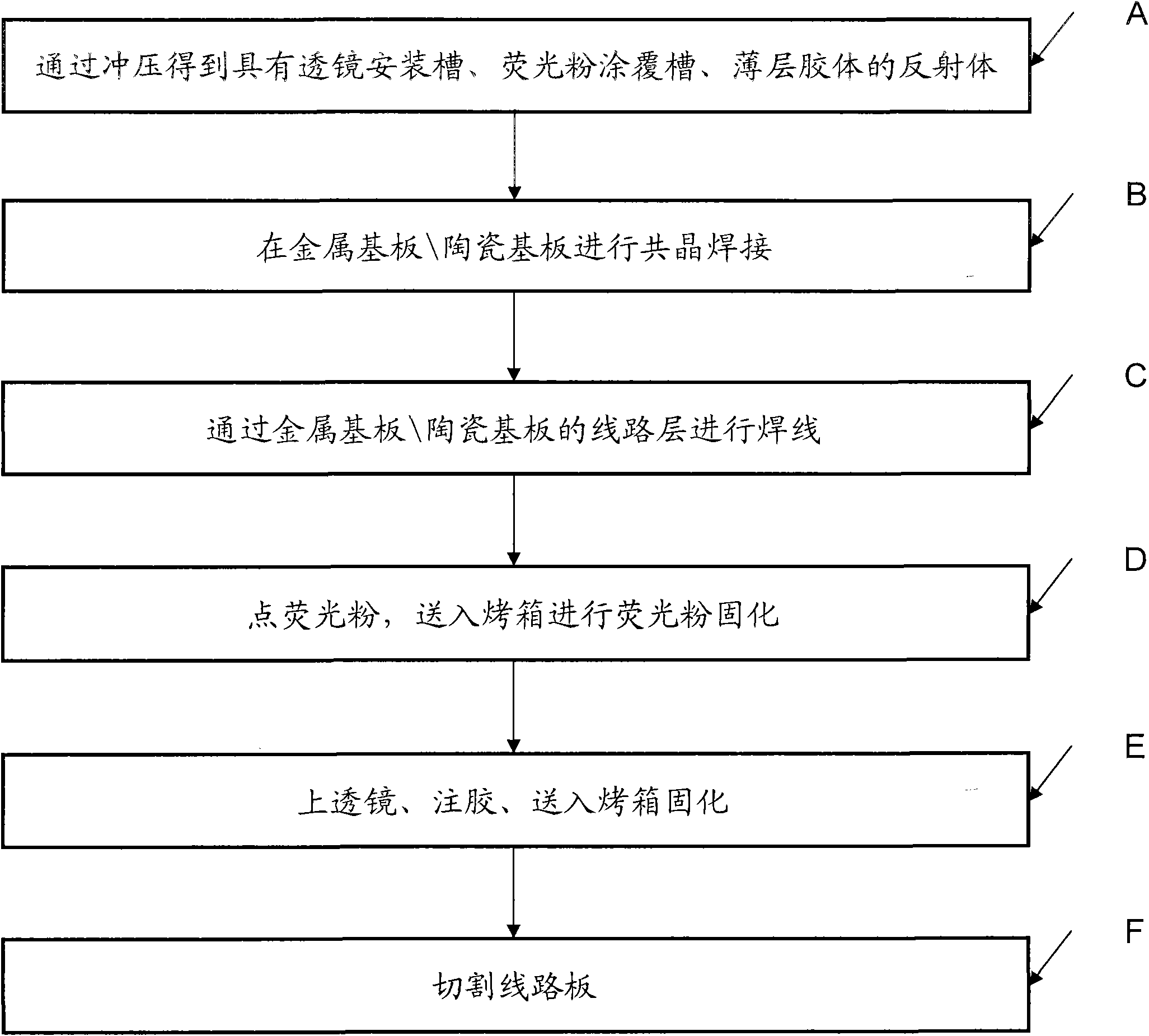

[0041] The invention provides a packaging method of a high-power white light LED based on a metal substrate. Firstly, a metal substrate is designed, by punching out the lens mounting groove, the phosphor coating groove and the electrode pad, and forming an insulating layer on the substrate, and forming a eutectic pad, a reflective metal layer, leads and wires by screen printing. metal pads. Eutectic bonding of the chip is then performed on the metal substrate. Point the phosphor powder and send it to the oven for phosphor curing. Put on the lens, inject glue, and send it to the oven for curing. Cut the circuit board to obtain the high-power LED packaged on the substrate.

[0042] In the present invention, the metal substrate structure is as Figure 4 to Figure 7. For the convenience of description, only one unit is used for illustration; the substrate can use a single-row structure of 1×12 units, or a double-row structure of 2×10 units, or other suitable unit arrangements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com