Algae growth for biofuels

A technology of algae and plants, which is applied in the field of algae growth in the manufacture of biofuels, and can solve problems such as easy evaporation of water, difficult temperature control, and high danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

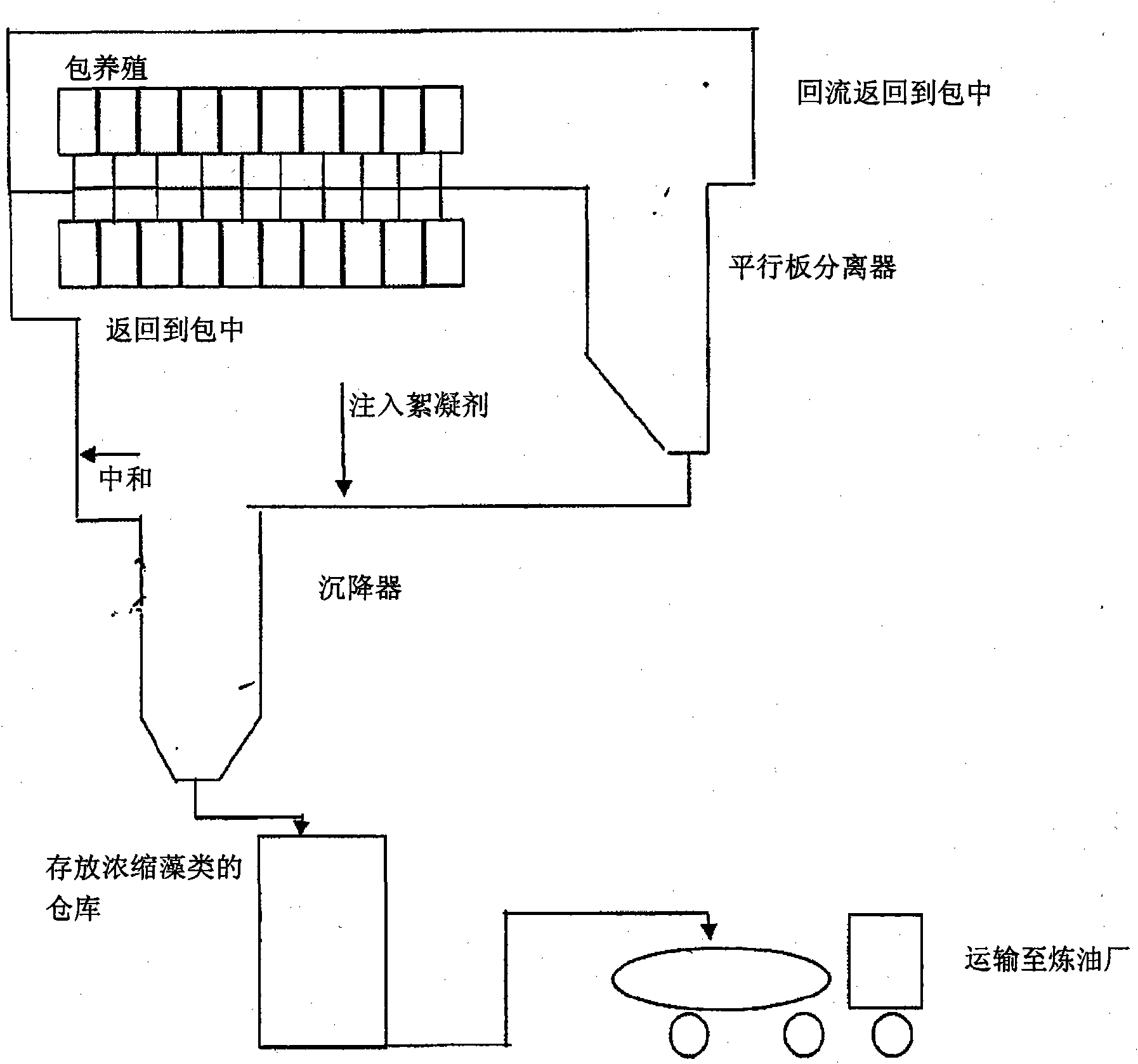

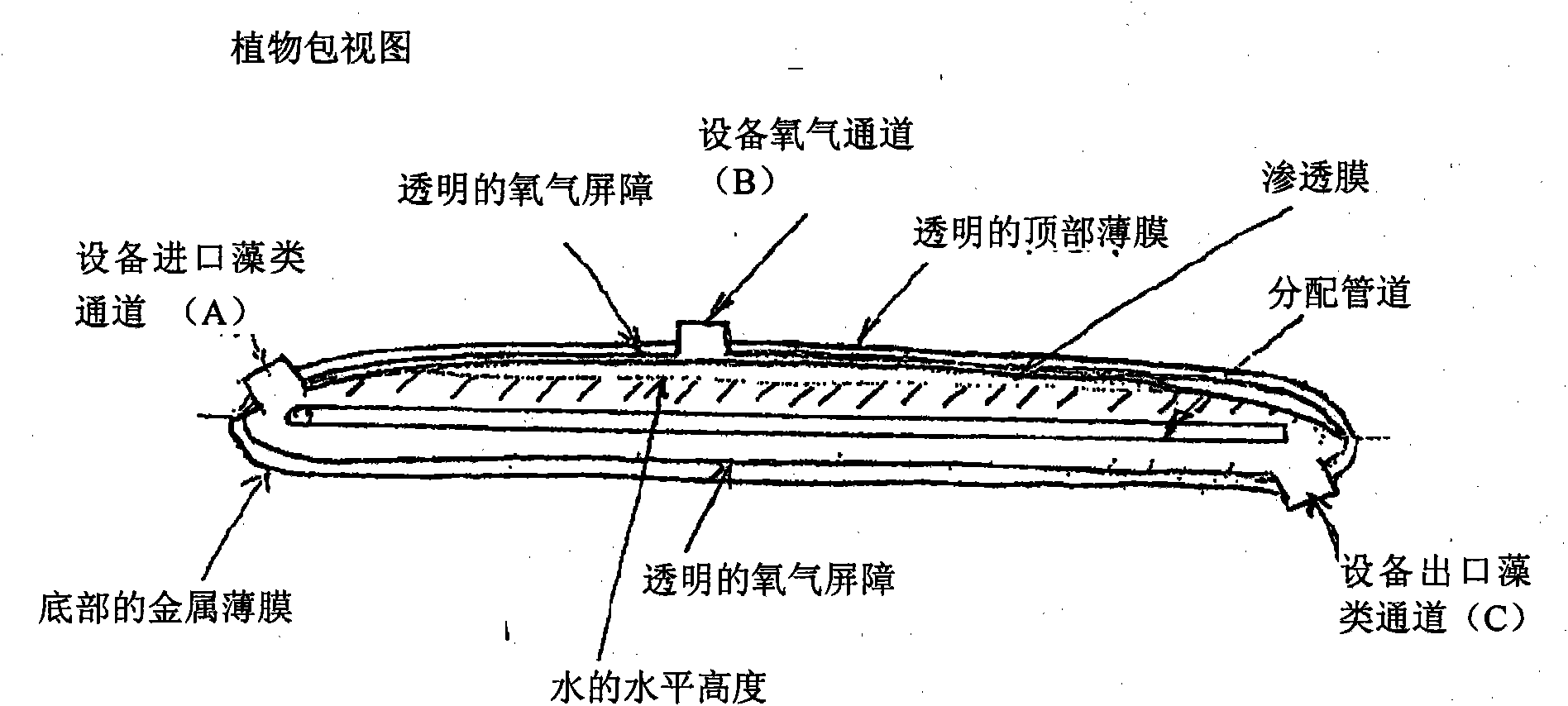

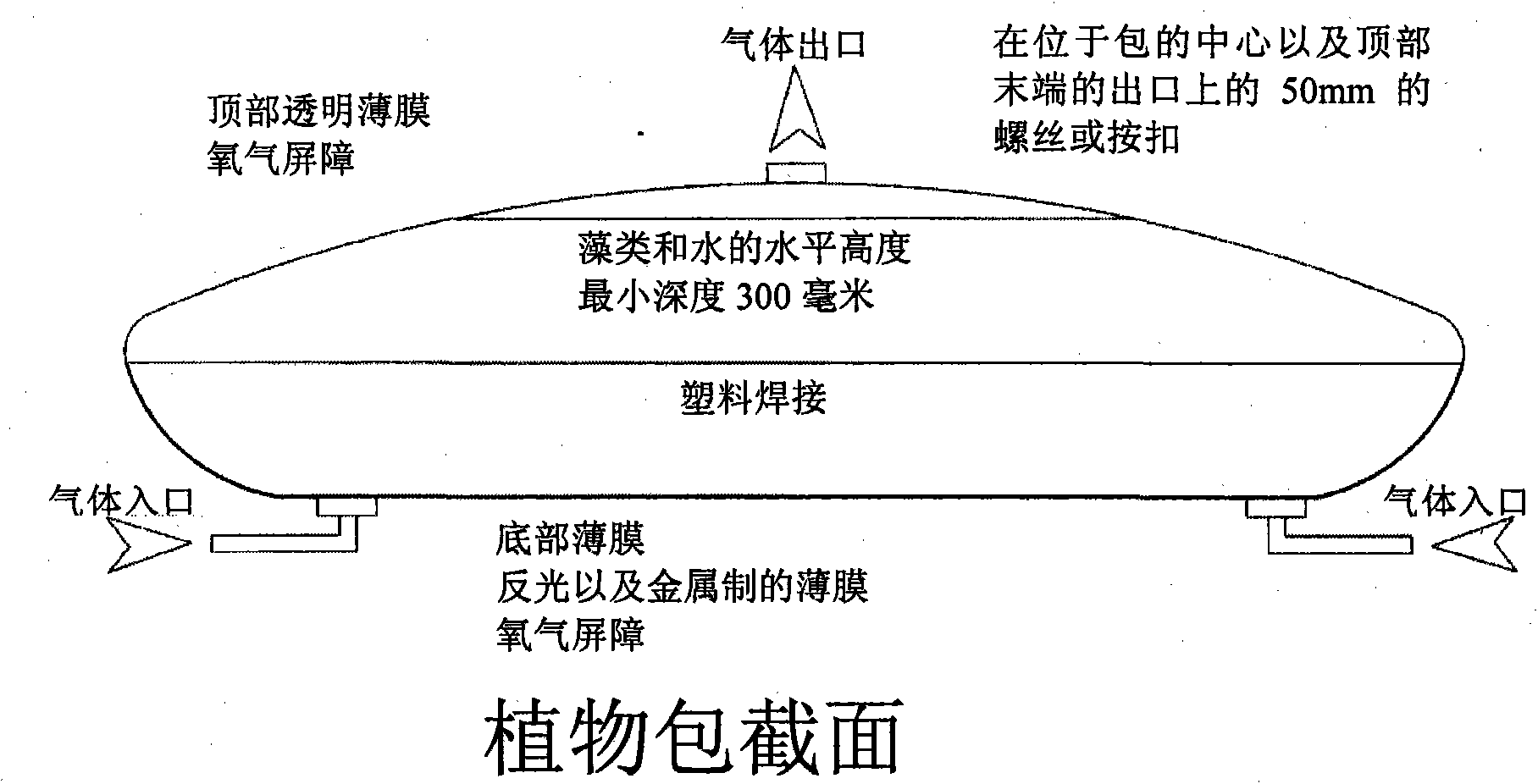

Method used

Image

Examples

Embodiment 1

[0143] In a particular example of the present invention, the algae used are of the following species

[0144] Nannochloropsis, which includes the following characteristics

[0145] An immobile green flagellated cell

[0146] A small cell, 4-6 microns in diameter

[0147] • The cell area floats in the medium and remains suspended without aeration.

[0148] The necessary growth conditions are

[0149] ·Temperature 20-30℃

[0150] ·Lighting 2500-6000Lux

[0151] ·pH 7.5-8.5

[0152] · Salinity 10-36ppt

[0153] The nutritional requirements are:

[0154] ■NaNO 3 -150mg / l

[0155] ■NaHPO 4 -8.69mg / l

[0156] ■ Iron EDTA-10mg / l

[0157] ■MnCl 2 -0.22mg / l

[0158] ■CoCl 2 -0.11mg / l

[0159] ■CuSO 4 , 5H 2 O-0.0196mg / l

[0160] ■ZnSO 4 , 7H 2 O-0.044mg / l

[0161] ■Na 2 SiO 3 , 2H 2 O-60mg / l

[0162] ■B 12 -1.0μg / l

[0163] ■Biotin-1.0μg / l

[0164] ■Thiamine hydrochloride-0.2mg / l

[0165] When using CO 2 , common practice is to use a timer to inject inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com