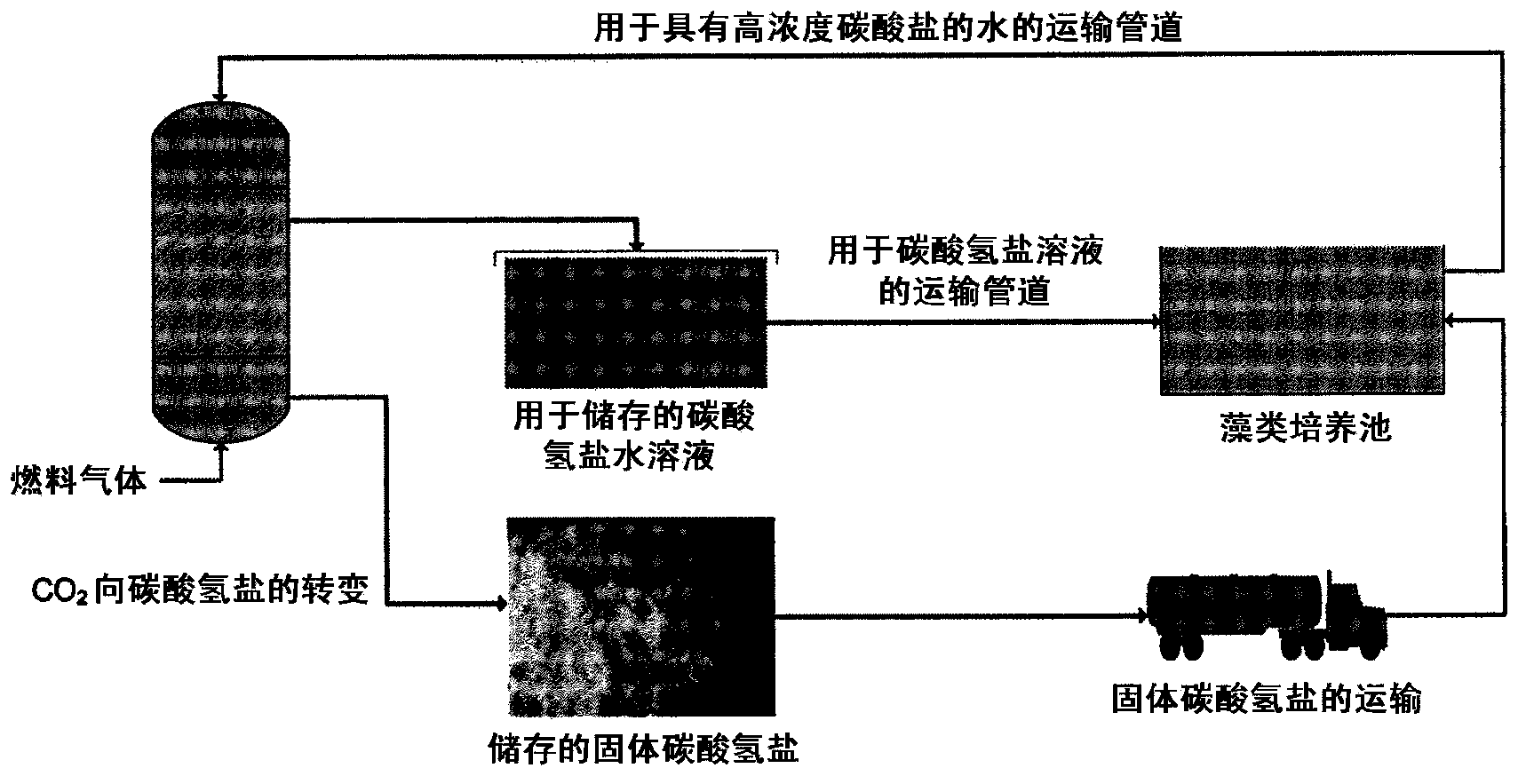

Integrated carbon capture and algae culture

A technology of algae and culture medium, applied in the field of integrated carbon capture and algae cultivation, which can solve problems such as low efficiency, high transmission cost, and high cost of carbon capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Strains and media

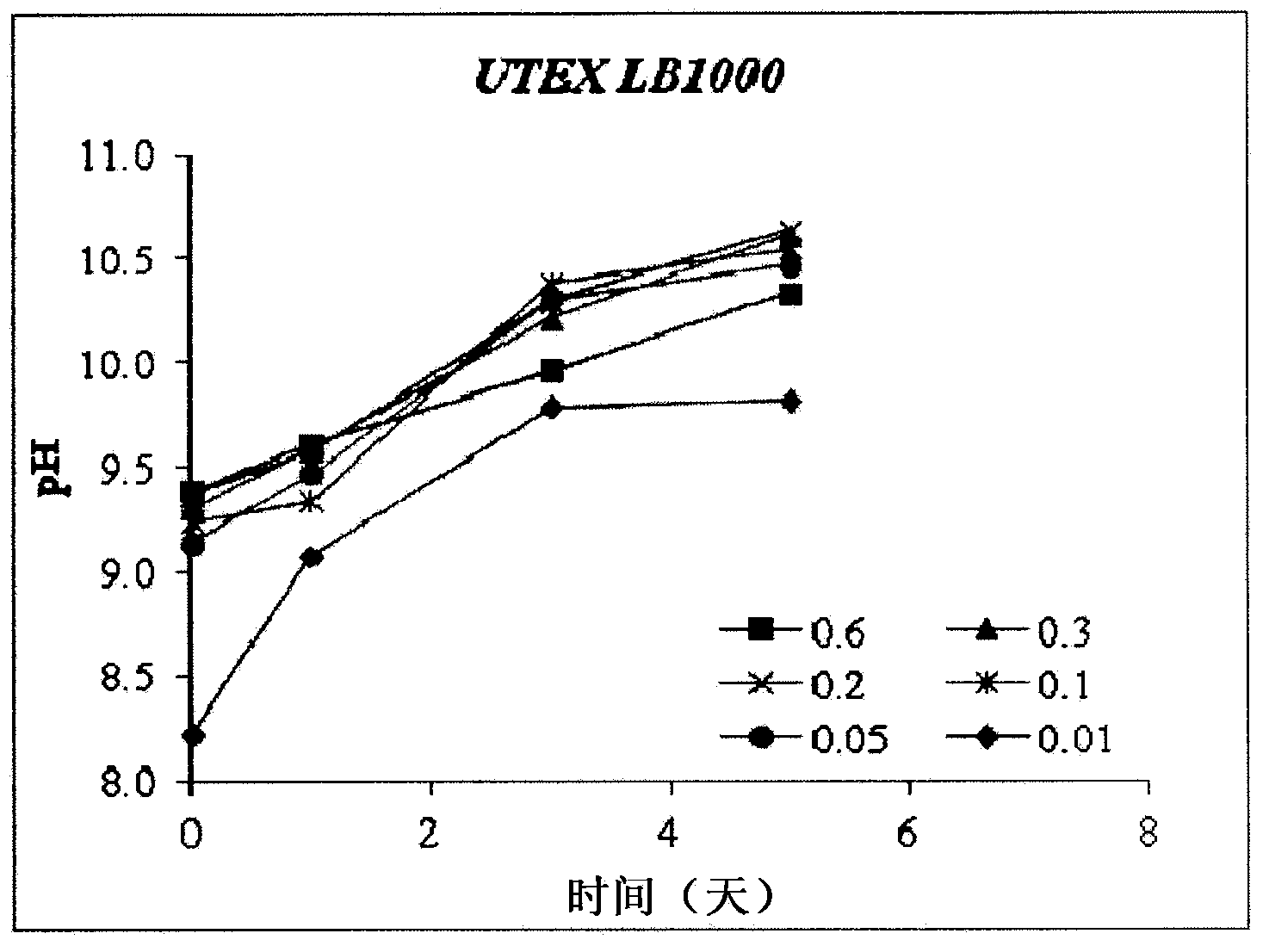

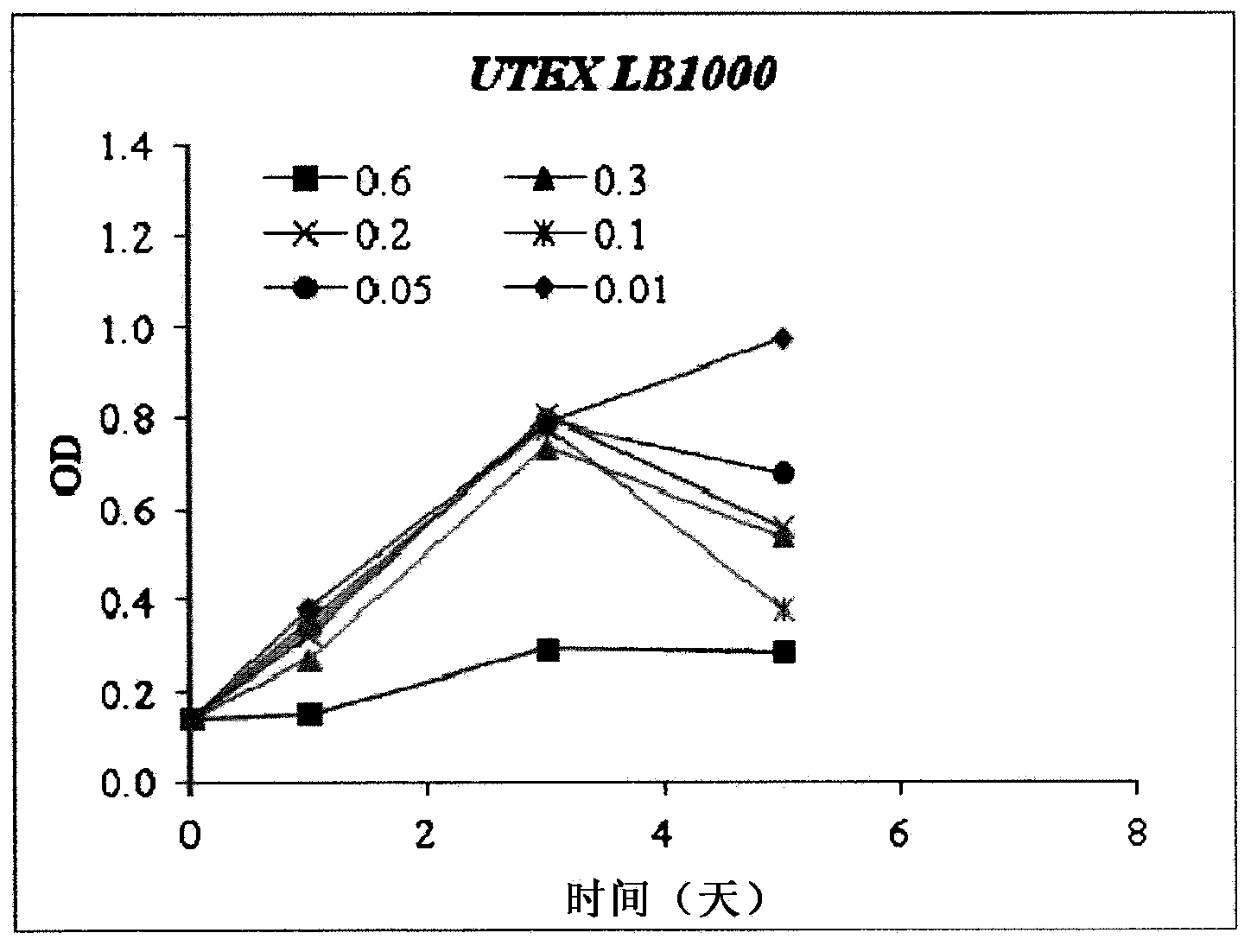

[0053] Dunaliella primolecta (UTEXLB1000) was cultured using artificial seawater medium (UTEX) with reduced concentrations of calcium (5% of the original concentration) and magnesium (10% of the original concentration).

[0054] 2. Well plate culture

[0055] Culture cells in 24-well plates with 2 mL per well. The temperature of the culture room was controlled at 20°C. Different concentrations of sodium bicarbonate were used as an inorganic carbon source, and there was no CO 2 Gas is fed into the culture. Light distribution was measured for each sample using light at a wavelength of 750 nm.

[0056] Dunaliella salina grew to its maximum growth on the third day of culture (Fig. 2). When the pH exceeded 10.0, the pH further increased after 3 days of culture, and the final pH was close to 10.5 in some cultures. Furthermore, its growth in 0.3M bicarbonate was at the same level as growth using lower concentrations, but 0.6M bicarbonate result...

Embodiment 2

[0061] 1. Strains and media

[0062] The unicellular blue-green algae (Euhalothece) ZM001 was cultured with 1.0M sodium bicarbonate concentration, and its composition was:

[0063] composition

concentration

refer to

NaHCO 3

84g / L

KNO 3

2.5g / L

KCl

2g / L

Na 2 SO 4

1.4g / L

K 2 HPO 4

0.38g / L

A5 trace elements

1mL / L

(Mikhodyuk et al., 2008)

pH

9.5

[0064] 2. Cultivation in the Photo-bioreactor

[0065] Cells were grown in the photobioreactor with agitation but without aeration. The optical path for the photobioreactor is about 0.5 cm, and the photobioreactor is placed at an intensity of 100 μmol / m 2 / s light. The culture temperature was 35°C.

[0066] The initial pH was adjusted to 9.5 with sodium hydroxide. Using an inoculum concentration of 1.2 g / L, the final biomass concentration in this culture was 4.8 g / L and the daily...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com