Methods and apparatus for cooling syngas within gasifier system

一种合成气、合成气冷却器的技术,应用在激冷环领域,能够解决表面不均匀、受限空间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

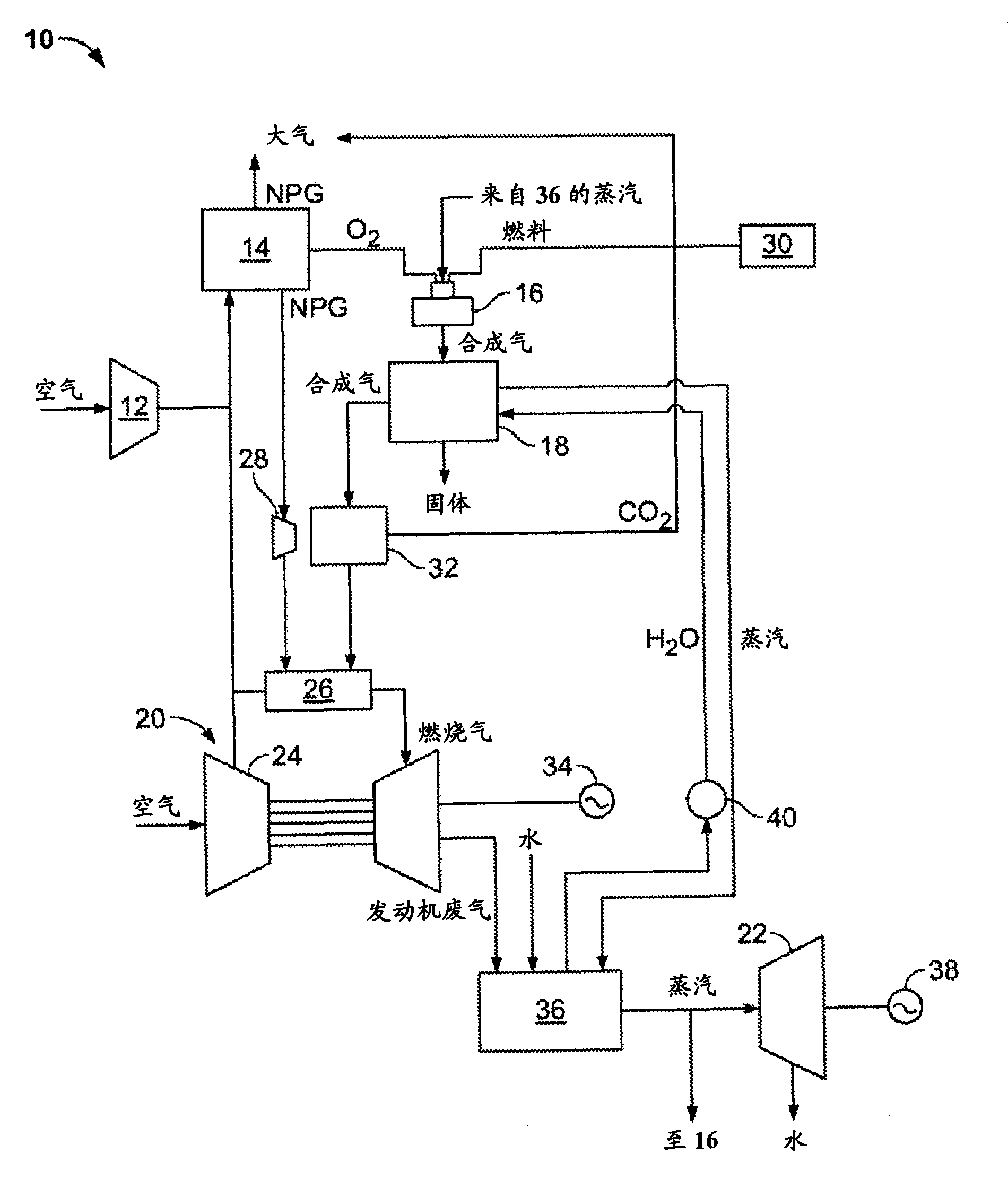

[0012] figure 1 is a schematic diagram of an exemplary integrated gasification combined cycle (IGCC) power generation system 10 . The IGCC system 10 generally includes a main air compressor 12, an air separation unit (ASU) 14 coupled in flow communication to the compressor 12, a gasifier 16 coupled in flow communication to the ASU 14, a gasifier 16 coupled in flow communication to the gas A syngas cooler 18 of the carburetor 16 , a gas turbine engine 20 coupled in flow communication to the syngas cooler 18 , and a steam turbine 22 coupled in flow communication to the syngas cooler 18 .

[0013] In operation, compressor 12 compresses ambient air, which is then channeled to ASU 14 . In the exemplary embodiment, compressed air from gas turbine engine compressor 24 is supplied to ASU 14 in addition to compressed air from compressor 12 . Alternatively, compressed air from gas turbine engine compressor 24 is supplied to ASU 14 instead of compressed air from compressor 12 . In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com