Working vehicle and amount controlling method of working oil thereof

A technology for operating vehicles and hydraulic oil, which is applied to control devices, vehicle components, mechanically driven excavators/dredgers, etc., can solve problems such as power loss, and achieve the effect of improving operating efficiency and increasing hydraulic oil volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

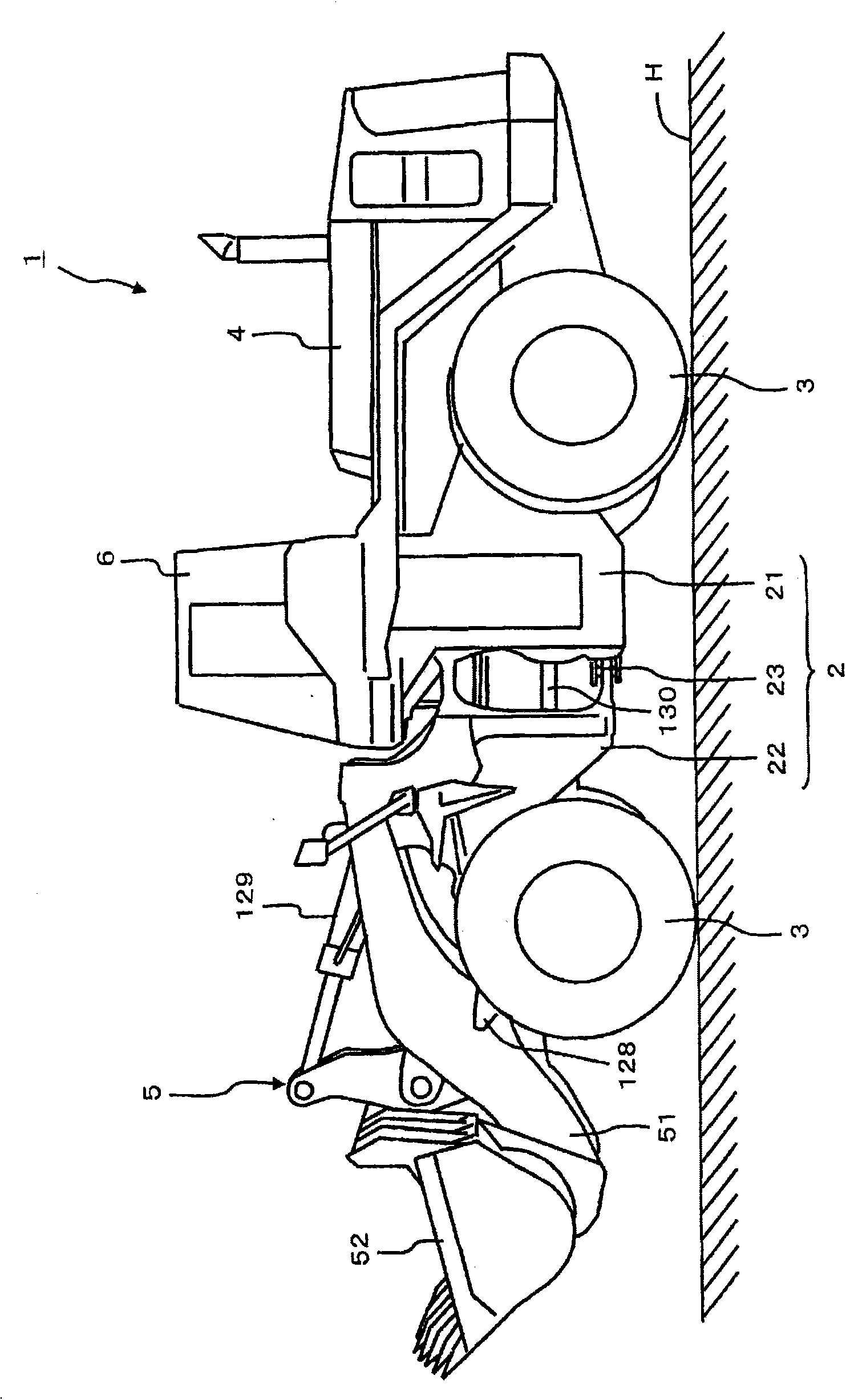

[0052] Next, a case where an embodiment of the present invention is applied to a wheel loader as a work vehicle will be described as an example. However, this embodiment can also be applied to work vehicles other than wheel loaders.

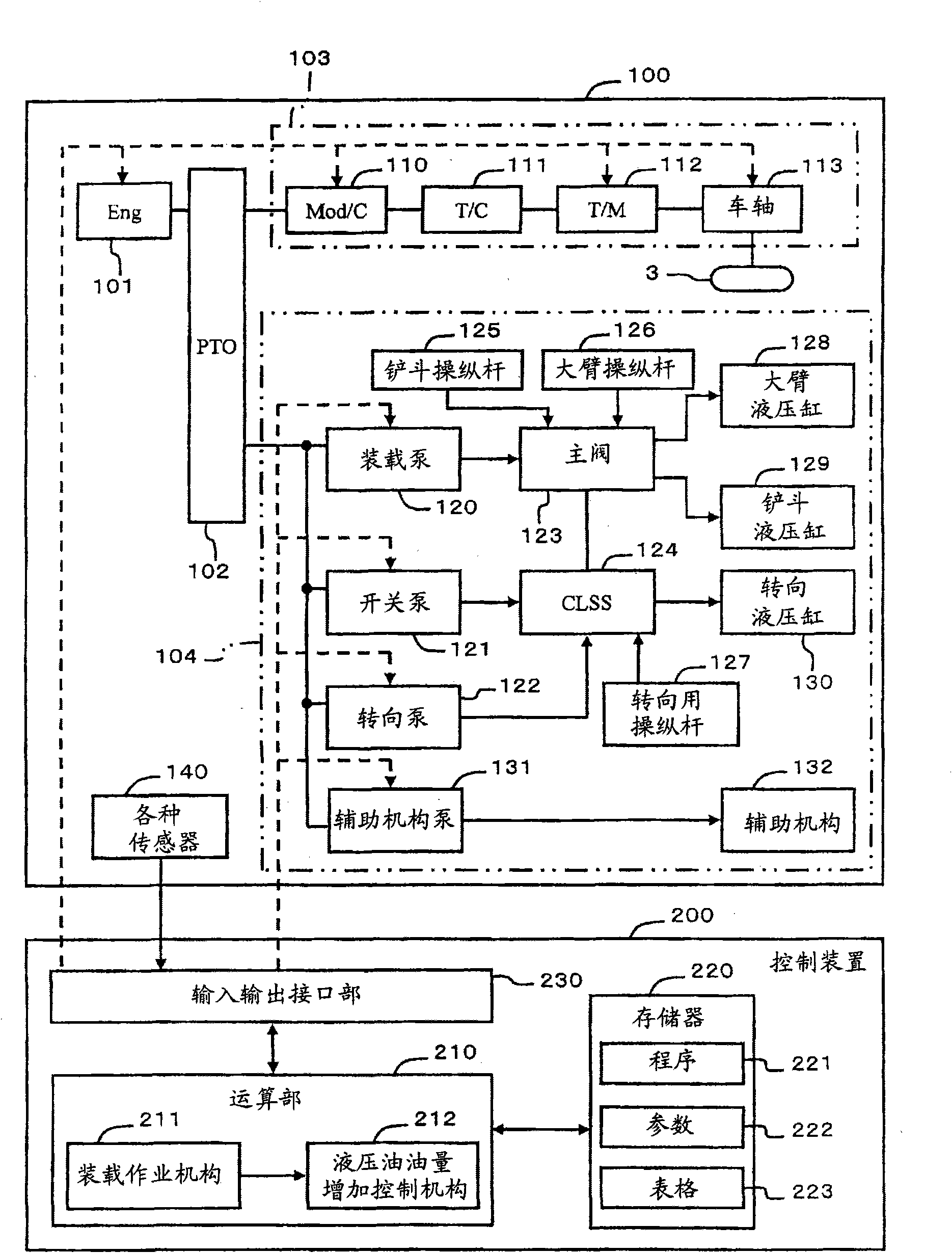

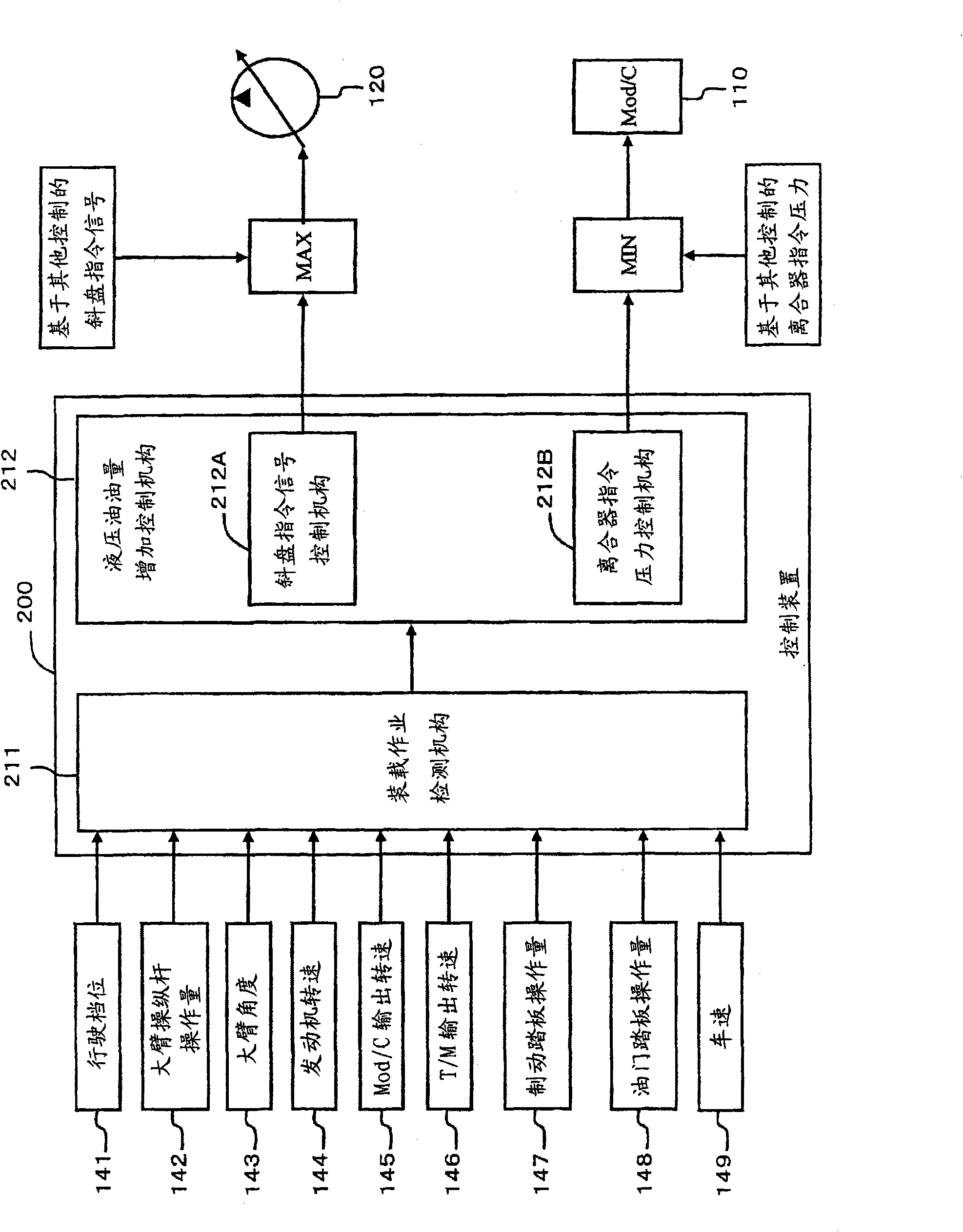

[0053] figure 1 It is an explanatory diagram schematically showing the overall structure of the wheel loader. The wheel loader is roughly divided into a mechanical structure 100 and a control structure (hereinafter referred to as a controller) 200 . First, the mechanical structure 100 will be explained, and then the controller 200 will be explained.

[0054] The mechanical structure 100 has, for example, an engine 101 , an output distributor (PTO: Power Take Off) 102 for distributing the output of the engine 101 to a traveling system 103 and a hydraulic system 104 , and a traveling system 103 for driving the wheel loader 1 , And the hydraulic device system 104 mainly used to drive the working device 5 .

[0055] refer here image 3 . image...

Embodiment 2

[0110] Next, a modified example of the processing for detecting loading work will be described. The following embodiments correspond to modified examples of the first embodiment. exist Figure 11 In the shown second embodiment, the controller 200 determines whether the boom joystick 126 is operated in the upward direction (S10) and whether the boom angle θb is greater than the specified angle θ1 (S11). When both conditions are satisfied, It is determined that the loading operation is being performed (S14).

[0111] The present embodiment constituted in this way also obtains the same effects as those of the first embodiment described above. In this embodiment, since the process of detecting the loading operation is simpler than that of the first embodiment, the control program can be simplified compared with the first embodiment.

Embodiment 3

[0113] exist Figure 12 In the third embodiment shown, the controller 200 respectively determines the first condition (S10) and the fourth condition (S13) described in the first embodiment, and when the two conditions are satisfied, it is determined that the loading operation is in progress (S14). The present embodiment configured in this way also obtains the same effects as those of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com