Spoke-like vehicle body automatic ordering buffer area and ordering method thereof

A technology of automatic sorting and buffering, which is applied in the direction of motor vehicles, conveyor objects, transportation and packaging, etc., can solve the problems of long sorting time and weak sorting ability, and achieves the effect of fast operation, improved flexibility and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

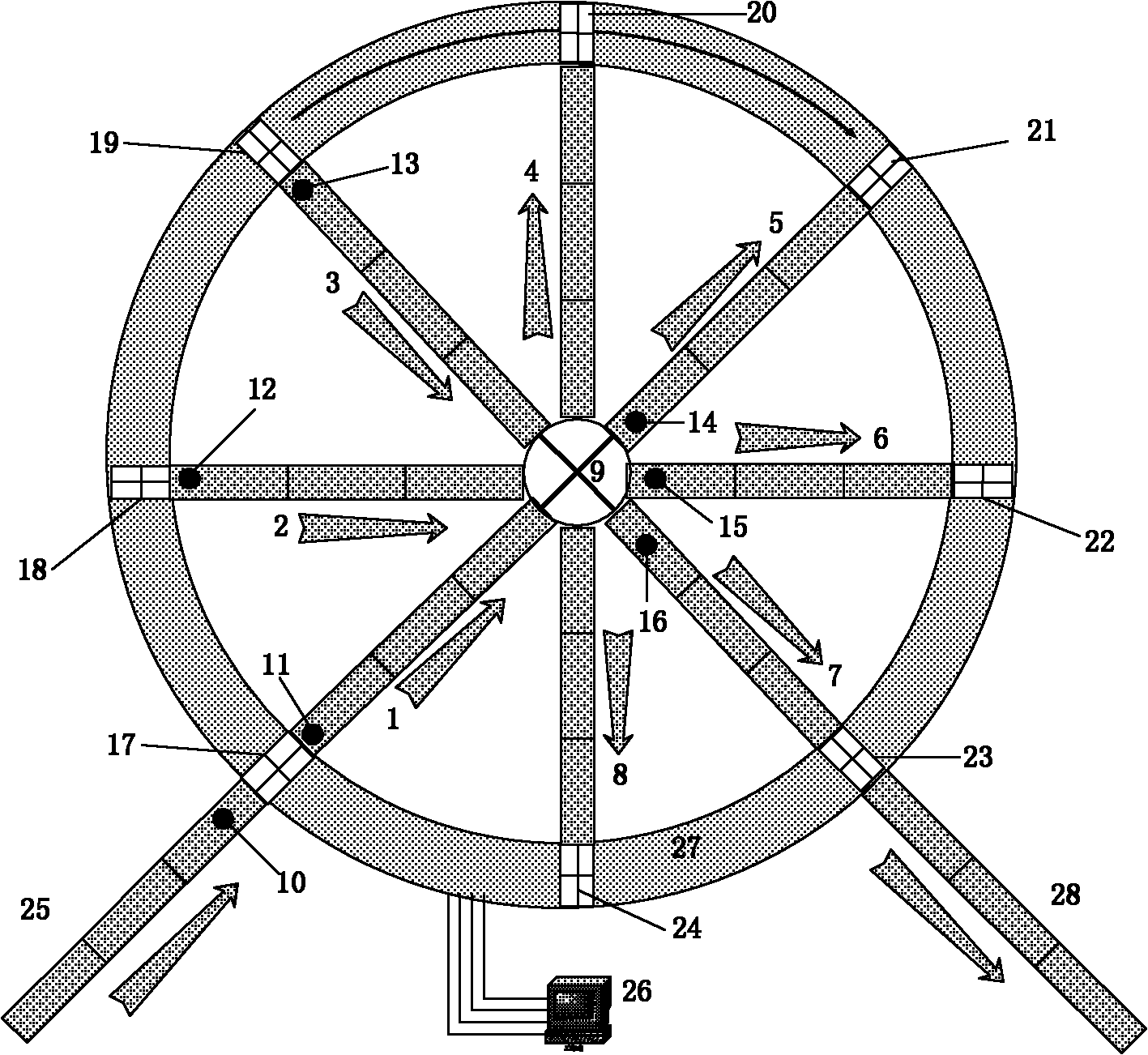

[0039] figure 1 Instructions marked in the middle: 1-3 is the first-level adjustment buffer track, 4-the second-level adjustment buffer front-adjustment track, 5-7 is the second-level adjustment buffer track, 8-the first-level adjustment buffer callback track, 9-transit adjustment Steering wheel, 10-16 are sensors, 17-24 are cross track, 25-entrance track, 26-intelligent monitoring system terminal computer, 27-segmented arc scheduling track, 28-exit track.

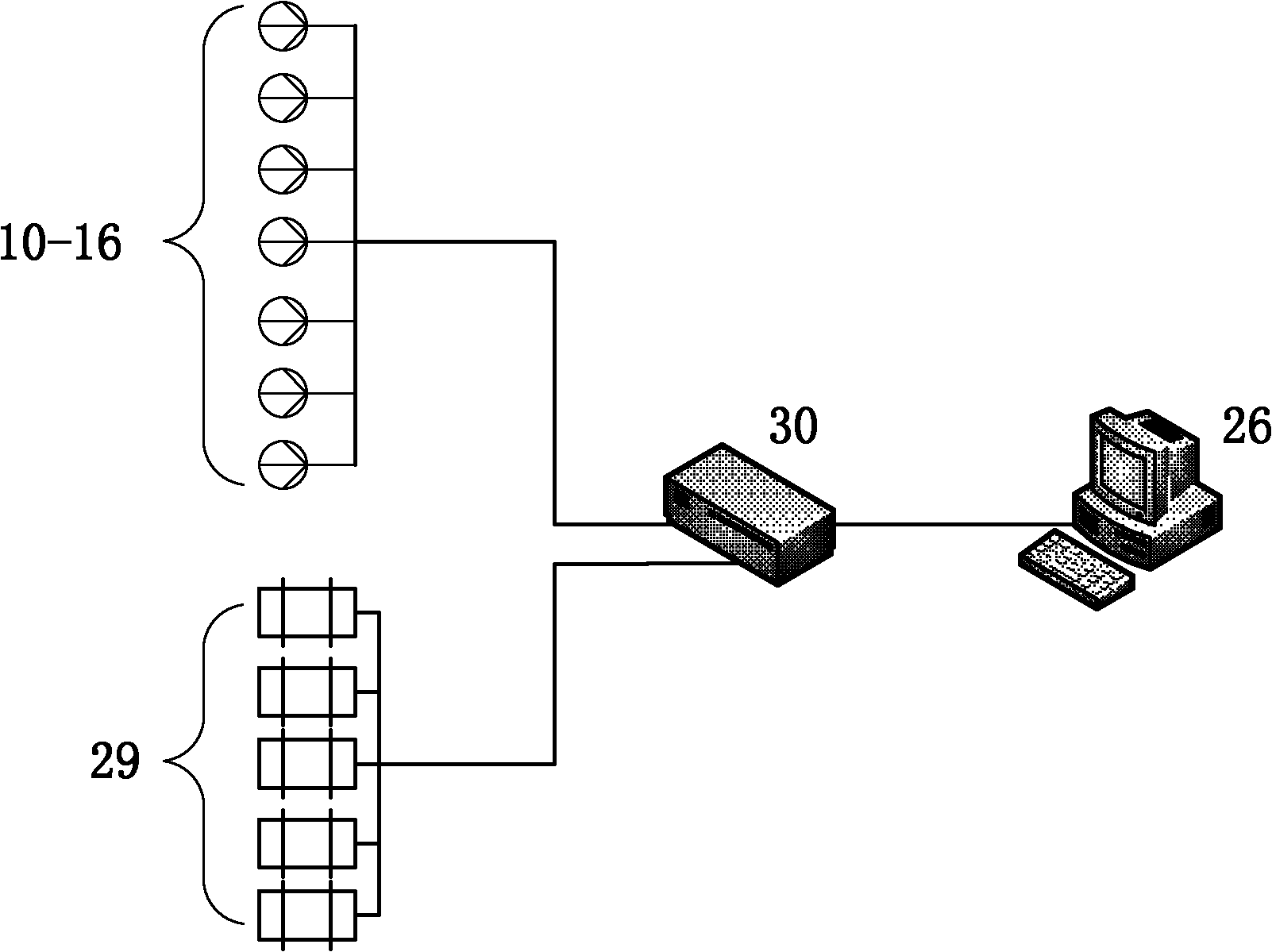

[0040] figure 2 Instructions marked in the middle: 10-16 is the sensor, 29-control motor, 30-signal conversion module, 26-computer

[0041] Figure 4 Explanation of middle marks: the horizontal axis represents different colors, and the vertical axis represents the quantity of each color body

[0042] Figure 5 Explanation of marks in middle: the horizontal axis represents different types of ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com