Ordered mesoporous carbon material with ultra-large aperture and controllable wall thickness and preparation method thereof

A technology of mesoporous materials and mesoporous carbon, applied in the field of advanced nanoporous materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

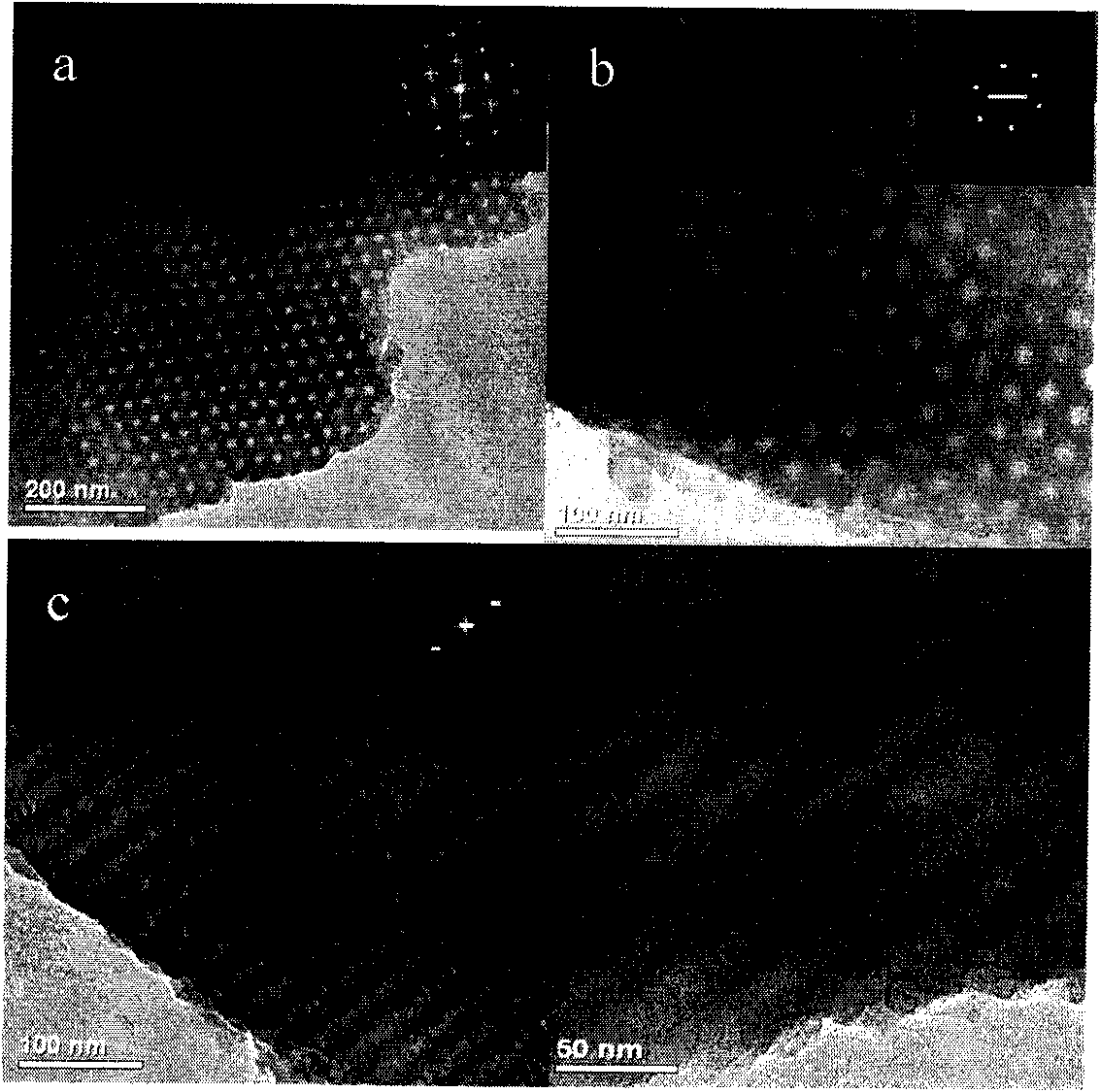

[0019] Synthesis of Mesoporous Carbon Materials with Ultra-Large Pore Size:

[0020] 1. Combine A-stage phenolic resin (Resol) and block copolymer surfactant PEO containing polyoxyethylene segment 45 -b-PMMA 30 -b-PS 48 Dissolve in tetrahydrofuran. Wherein, the content of A-stage phenolic resin is 4.5-14 wt%, the block copolymer surfactant containing polyoxyethylene segment is 1 wt%, and the rest is solvent.

[0021] 2. Pour 4.5 g of the mixed solution in the above step into two petri dishes with a diameter of 15 cm, and let the solvent evaporate naturally for 1 day at room temperature to form a mesoscopic structure.

[0022] 3. After the above-mentioned solvents are completely evaporated, the samples obtained from the evaporation are baked in an environment of 100 degrees for 48 hours to cure the phenolic resin to fix the mesoscopic structure.

[0023] 4. Put the cured sample in a tube furnace under the protection of inert gas and burn it at high temperature to remove the...

Embodiment 2

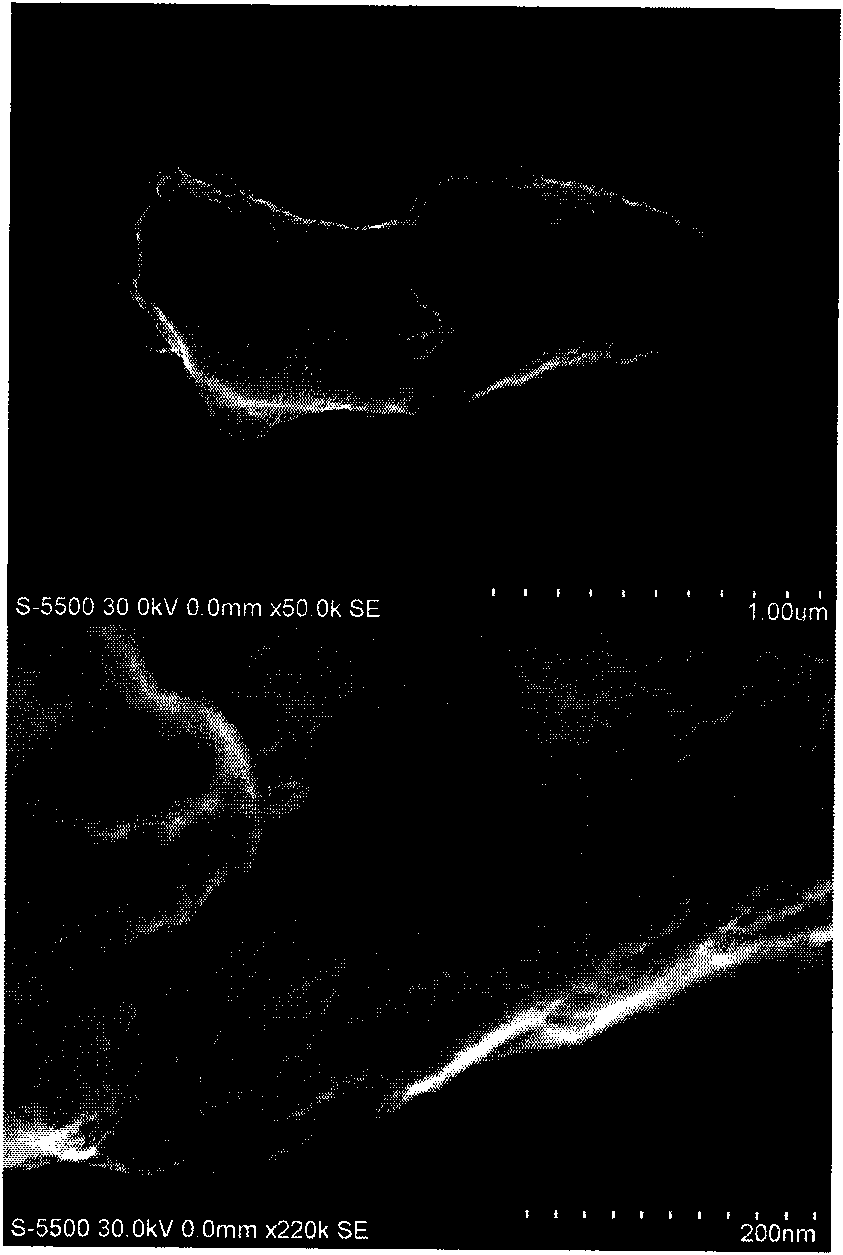

[0025] Synthesis of Mesoporous Polymer Materials with Ultra-Large Pores

[0026] 1. Combine A-stage phenolic resin (Resol) and block copolymer surfactant PEO containing polyoxyethylene segment 45 -b-PMMA 30 -b-PS 48Dissolve in tetrahydrofuran. Wherein, the content of A-stage phenolic resin is 4.5 wt%, the block copolymer surfactant containing polyoxyethylene segment is 1 wt%, and the rest is solvent.

[0027] 2. Pour 4.5 g of the mixed solution in the above step into two petri dishes with a diameter of 15 cm, and let the solvent evaporate naturally for 1 day at room temperature to form a mesoscopic structure.

[0028] 3. After the above-mentioned solvents are completely evaporated, the samples obtained from the evaporation are baked in an environment of 100 degrees for 48 hours to cure the phenolic resin to fix the mesoscopic structure.

[0029] 4. Put the cured sample in a tube furnace under the protection of inert gas to burn at high temperature to remove the surfactant,...

Embodiment 3

[0031] Synthesis of Mesoporous Carbon Materials with Ultra-Large Pore Size

[0032] 1. Combine A-stage phenolic resin (Resol) and block copolymer surfactant PEO containing polyoxyethylene segment 100 -b-PMMA 80 -b-PS 70 Dissolve in tetrahydrofuran. Wherein, the content of A-stage phenolic resin is 4.5-14 wt%, the block copolymer surfactant containing polyoxyethylene segment is 1 wt%, and the rest is solvent.

[0033] 2. Pour 4.5 g of the mixed solution in the above step into two petri dishes with a diameter of 15 cm, and let the solvent evaporate naturally for 1 day at room temperature to form a mesoscopic structure.

[0034] 3. After the above-mentioned solvents are completely evaporated, the samples obtained from the evaporation are baked in an environment of 100 degrees for 48 hours to cure the phenolic resin to fix the mesoscopic structure.

[0035] 4. Put the cured sample in a tube furnace under the protection of inert gas and burn it at high temperature to remove the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com