Kilowatt-grade high-power movable type laser washing system

A high-power laser, laser cleaning technology, applied in the direction of laser welding equipment, cleaning methods and tools, manufacturing tools, etc., can solve the problems that the thick rust layer cannot be removed quickly, the volume and weight of the equipment are large, and it is not provided. Facilitate engineering application, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

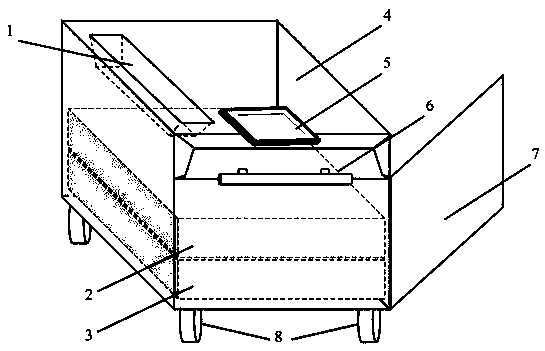

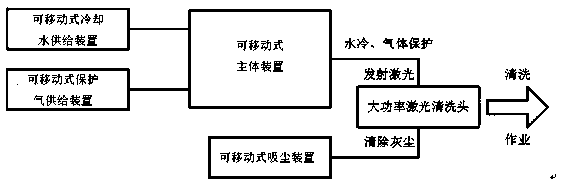

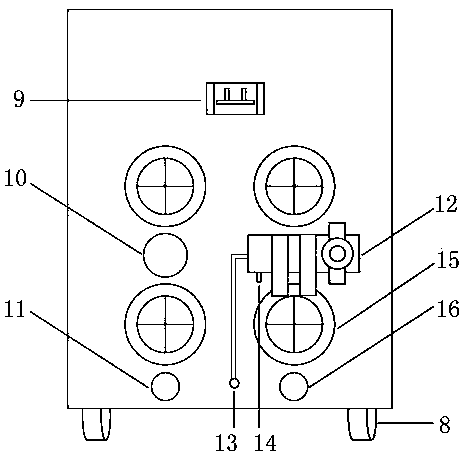

[0021] The specific implementation manner of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0022] Such as Figure 1-3 As shown, a kilowatt-level high-power portable laser cleaning system includes a movable main unit, a high-power laser cleaning head, a movable cooling water supply device, a movable protective gas supply device and a movable dust collector. device, the movable main body device, the movable cooling water supply device, the movable protective gas supply device and the movable dust collection device are all conveniently moved by setting rollers on them, and other conventional realizations that they can be moved The means are also within the protection scope of the present invention; the cooling water supply device, the shielding gas supply device and the dust suction device all belong to the prior art, and will not be described in detail here. The movable main device includes a kilowatt-level high-power las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com