Continuous large-area zinc oxide nano-sheet and preparation method thereof

A zinc oxide nanometer and large-area technology, applied in the field of nanomaterials, can solve the problems of lack of zinc oxide nanostructures and the inability to realize large-area, repeatable and low-cost preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Further illustrate content of the present invention below in conjunction with example:

[0028] Case 1: Preparation of porous zinc oxide film on the surface of metal aluminum without nanostructure

[0029] Set the surface area to 100cm 2Industrial pure aluminum, grade 1A95, soaked in acetone for 10 minutes, rinsed with deionized water, then immersed in a mixture of 6.0% by weight phosphoric acid and 1.8% by weight chromic acid at 60°C for 30 minutes to remove the surface oxide layer.

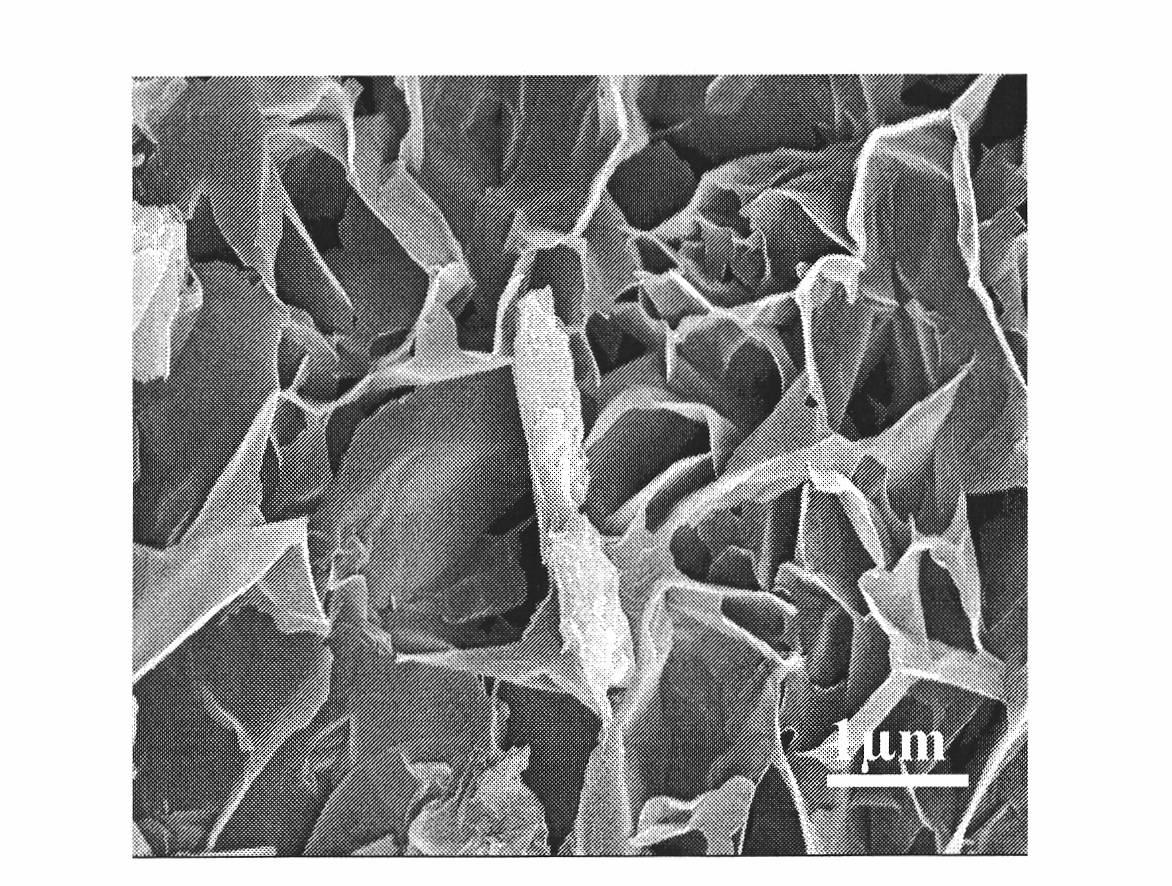

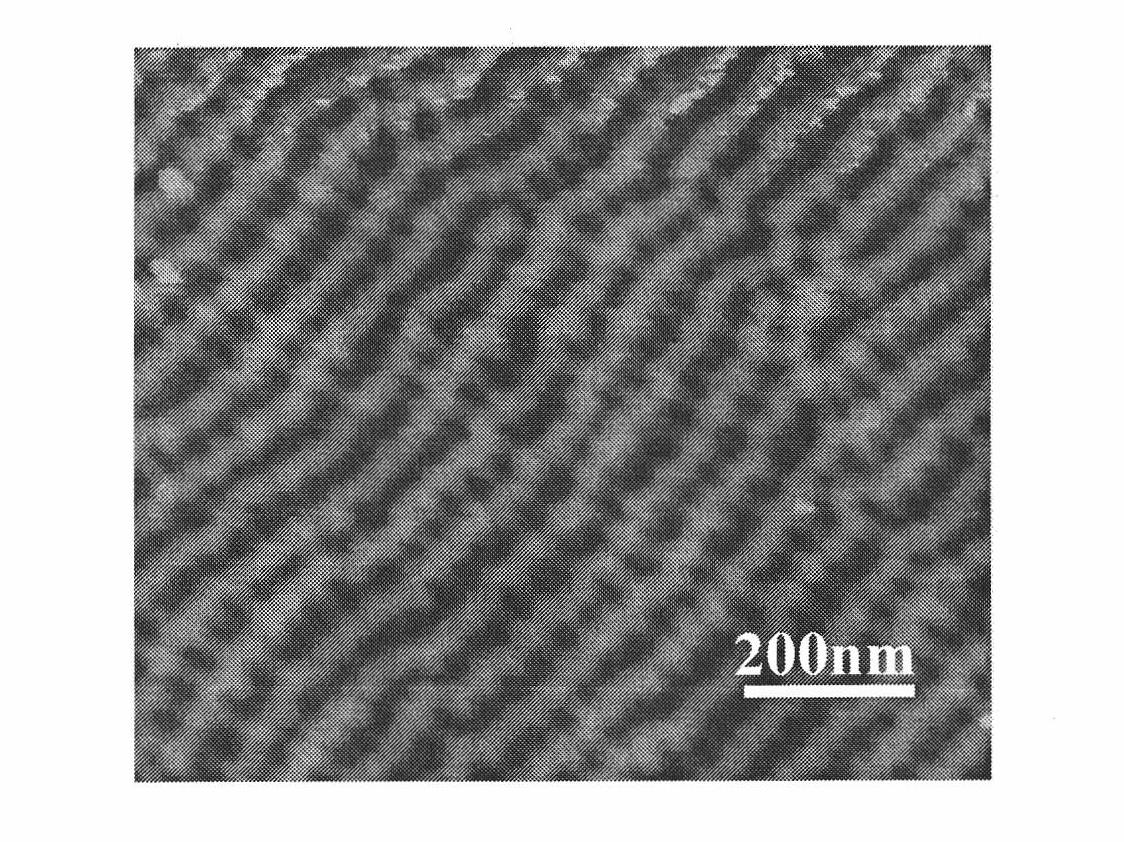

[0030] Put the aluminum substrate into the beaker, add 0.005mol Zn(NO 3 ) 2 , 0.005 mol of hexamethylenetetramine was prepared into 1000ml of solution, and heated in an oven at 100°C for 1 hour. After the reaction, the sample was taken out from the beaker, and dried in an oven at 60°C. The surface morphology of the obtained porous ZnO is as follows: figure 1 shown. The thickness of the zinc oxide flakes is about 10-20 nm, and many zinc oxide flakes are interconnected to form a contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com