Redispersable emulsion powder-modified antiblocking agent, preparation method thereof and application thereof

A technology of redispersing latex powder and anti-caking agent, which is applied in the field of redispersible latex powder modified anti-caking agent, which can solve the problems of no caking, affecting the performance of rubber powder, and the shelf life of rubber powder, so as to achieve stable products Quality, the effect of improving anti-caking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

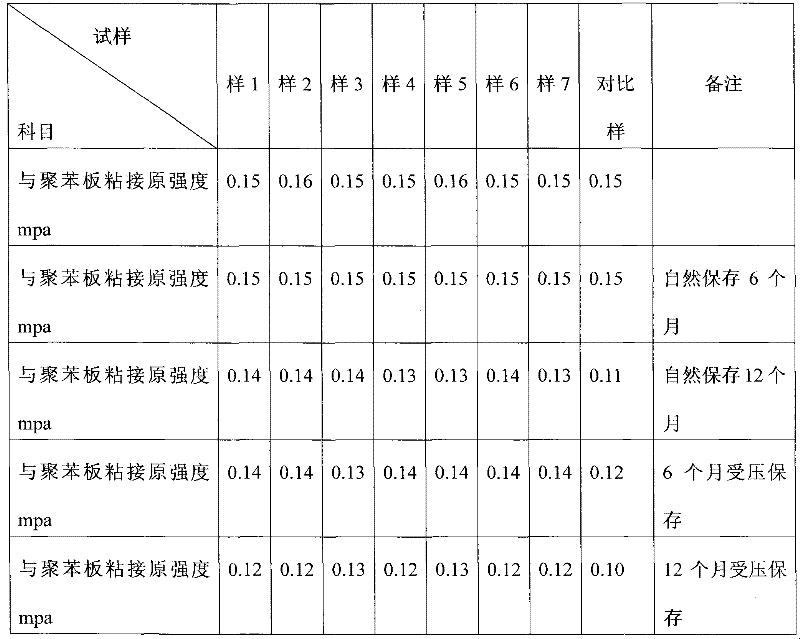

Image

Examples

Embodiment 1

[0021] 100 parts of anhydrite powder (1000 mesh), 3 parts of stearic acid, 0.5 part of a monoalkoxyphthalate coupling agent, and 3 parts of 3-chloro-2-hydroxypropyltrimethylammonium chloride.

[0022] The preparation method is as follows: Add 100 parts of anhydrite (1000 mesh) into the mixing reactor, heat up to 75°C, add 3 parts of molten stearic acid, stir for 30 minutes (speed 50 rpm), and then add phthalic acid Ethanol solution of ester coupling agent, in the ethanol solution containing phthalate coupling agent, the weight content of phthalate coupling agent is 50%, continue stirring for 30 minutes, and finally add 3-chloro-2-hydroxypropyl trimethyl 3 parts of ammonium chloride, and then stirred for 60 minutes to make the finished product.

Embodiment 2

[0024] Anhydrite powder (1100 mesh) 100 parts, stearic acid 5 parts, monoalkoxyphthalate coupling agent 1 part, 3-chloro-2-hydroxypropyltrimethylammonium chloride 4 parts. .

[0025] The preparation method is as follows: add 100 parts of anhydrite (1100 mesh) into the mixing reaction kettle, heat up to 80°C, add 5 parts of molten stearic acid, stir for 30 minutes (speed 40 rpm), and then add phthalic acid 1 part of ester coupling agent, in the ethanol solution containing phthalate coupling agent, the weight content of phthalate coupling agent is 40%, continue stirring for 30 minutes, and finally add 3-chloro-2-hydroxypropyl trimethyl 4 parts of ammonium chloride, and then stirred for 60 minutes to make the finished product.

Embodiment 3

[0027] Anhydrite powder (1200 mesh) 100 parts, stearic acid 4 parts, monoalkoxy phthalate coupling agent 1.5 parts, 3-chloro-2-hydroxypropyltrimethylammonium chloride 5 parts.

[0028] The preparation method is as follows: add 100 parts of anhydrite (1200 mesh) into the mixing reaction kettle, heat up to 85°C, add 4 parts of molten stearic acid, stir for 30 minutes (speed 60 rpm), and then spray phthalate 1.5 parts of ester coupling agent (diluted with 1:1 alcohol), continue to stir for 30 minutes, and finally spray 5 parts of 3-chloro-2-hydroxypropyltrimethylammonium chloride, and stir for 60 minutes to obtain finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com