High temperature-resistant two-component acrylicester adhesive and preparation method thereof

A technology of acrylate and dimethacrylate, applied in the field of two-component acrylate adhesive and its preparation, can solve the problems of high temperature resistance performance limitation, affecting the application range of acrylate adhesive, etc., to improve high temperature resistance performance and excellent tensile strength. The effect of tensile and shear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

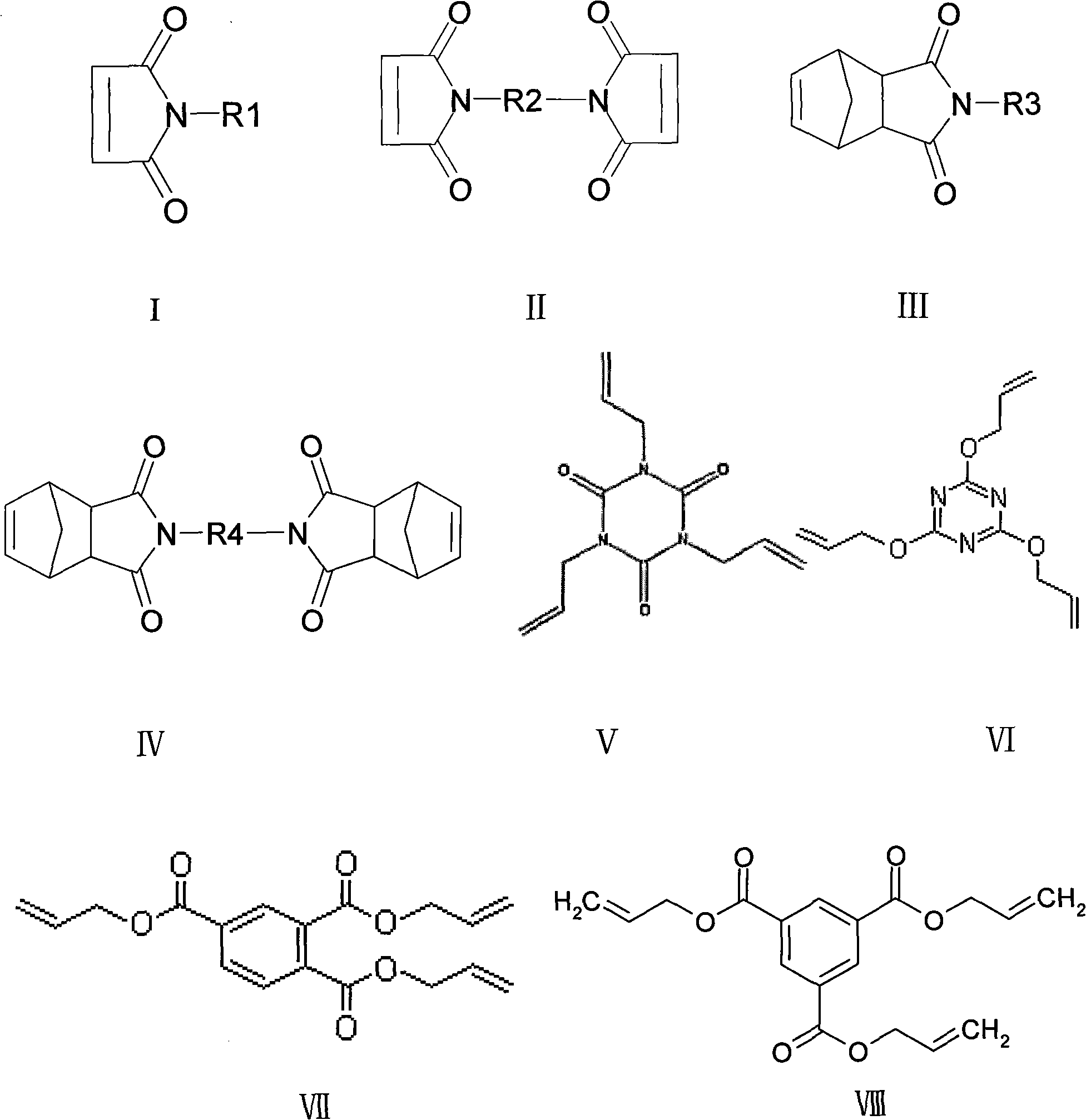

Method used

Image

Examples

Embodiment 1

[0019] Proportion A component B component

[0020] Methyl methacrylate 55% 42%

[0021] Methacrylic acid 5% 20%

[0022] Hydroxyethyl Methacrylate 15%

[0023] Nitrile Rubber 10%

[0024] ABS 25%

[0025] Substituted Thiourea 3%

[0026] Hydroquinone 0.1%

[0027] Cumyl Hydroperoxide 4.9%

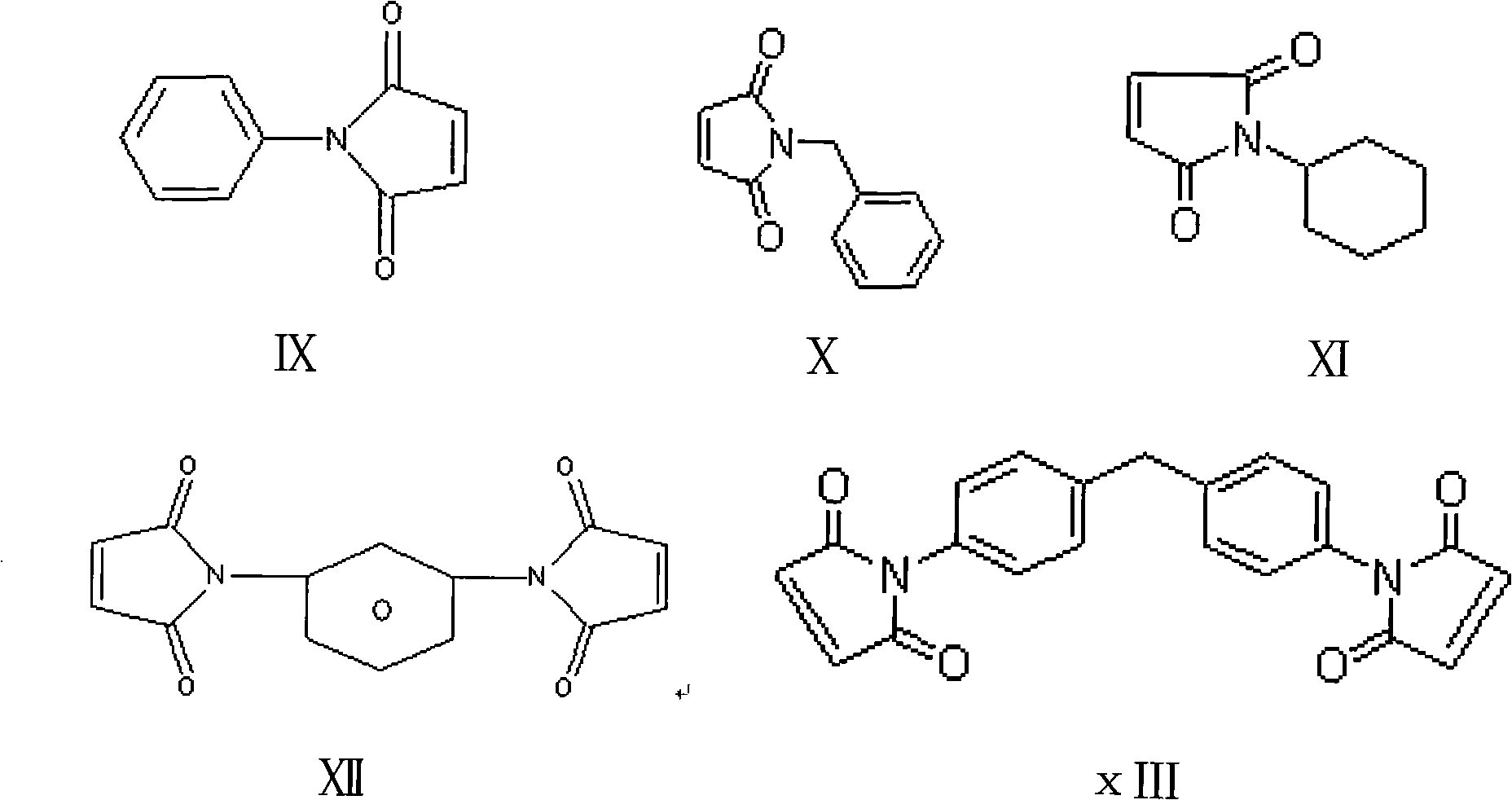

[0028] N-Phenylmaleimide ("NPM") 10% 10%

[0029] Preparation method: (1) Preparation of component A, add methyl methacrylate, methacrylic acid, and hydroquinone in a quantitative manner in a stirred tank and stir evenly, add ABS in a quantitative manner and stir until completely dissolved, then add NPM, in Stir at 30°C to 50°C for 3 to 4 hours, then add cumene hydroperoxide and stir evenly;

[0030] (2) For the preparation of component B, add methyl methacrylate, methacrylic acid, and hydroxyethyl methacrylate in a quantitative manner in a stirred tank and stir evenly, add nitrile rubber in a quantitative manner and replace thiourea and stir until completely dissolved, Then add NP...

Embodiment 2

[0034] Proportion A component B component

[0035] Diethylene glycol diacrylate 60% 50%

[0036] Methacrylic acid 5% 20%

[0037] Hydroxyethyl Methacrylate 10%

[0038] Nitrile rubber 7%

[0039] ABS 20%

[0040] Substituted Thiourea 3%

[0041] Hydroquinone 0.1%

[0042] Cumyl Hydroperoxide 4.9%

[0043] N-Phenylmaleimide ("NPM") 10% 10%

[0044] Preparation method: with reference to Example 1.

[0045] Performance test: with embodiment 1.

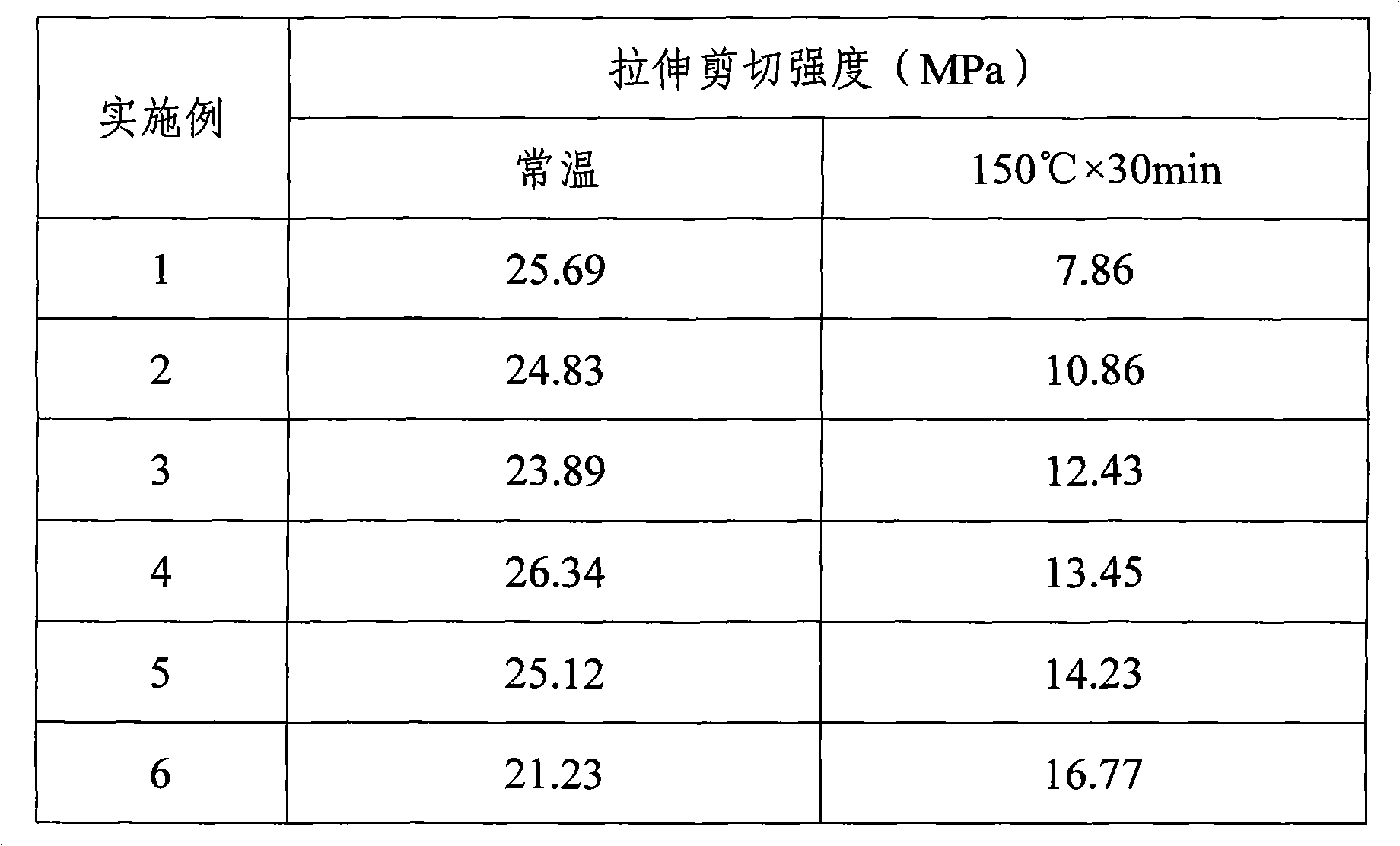

[0046] The test results are shown in Table 1.

Embodiment 3

[0048] Proportion A component B component

[0049] Ethoxylated bisphenol A dimethacrylate 60% 50%

[0050] Methacrylic acid 5% 20%

[0051] Hydroxyethyl Methacrylate 10%

[0052] Nitrile rubber 7%

[0053] ABS 20%

[0054] Substituted Thiourea 3%

[0055] Hydroquinone 0.1%

[0056] Cumyl Hydroperoxide 4.9%

[0057] N-Benzylmaleimide ("N-BEMI") 10% 10%

[0058] Preparation method: with reference to Example 1.

[0059] Performance test: with embodiment 1.

[0060] The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com