Ge-containing low-quenching sensitive aluminum alloy

A quenching sensitivity, aluminum alloy technology, applied in the field of low quenching sensitivity aluminum alloys, can solve the problems of uneven surface and core properties, difficult to obtain cooling rate, reduce cooling rate, etc., to improve the solid solution of solute atoms in the alloy Saturation, good core structure and mechanical properties, the effect of reducing quenching sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

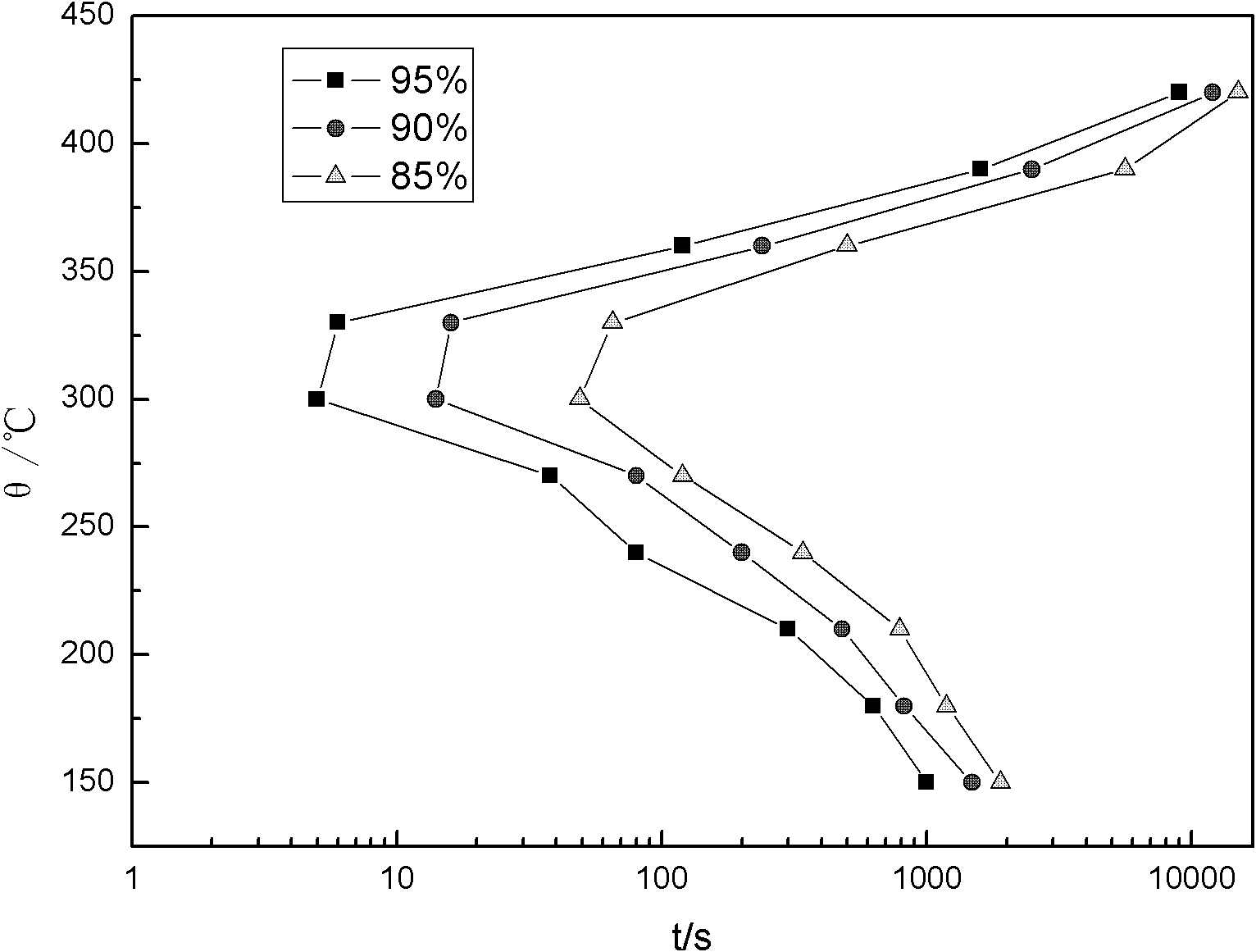

[0034] The alloy composition is 6.0% Zn, 1.1% Mg, 1.6% Cu, 0.13% Zr, 0.08% Ti, 0.5% Ge, the balance is Al, the purity of the Ge is greater than or equal to 99.99%, and it is smelted into an ingot. After homogenization treatment at 450°C / 24h+455°C / 24h, it is hot-rolled into a 4mm thick round bar plate with an extrusion ratio of 25. After the sample was solidified at 470°C / 1h, the nose time of the tested TTP curve was delayed by 25 seconds compared with that of the alloy without Ge, reaching 30 seconds. Although the strength of the Ge-added alloy sample aged after quenching in room temperature water is lower than that of the alloy without Ge, but when quenched in air, the tensile strength of the Ge-added alloy sample is 10Mpa higher than that of the Ge-free alloy, and the yield strength is 60Mpa higher. .

[0035] Energy spectrum analysis shows that after holding at the tip temperature (275°C) for 30 seconds, the precipitated phase of Ge-added alloy is only Mg-Ge compound, whil...

Embodiment 2

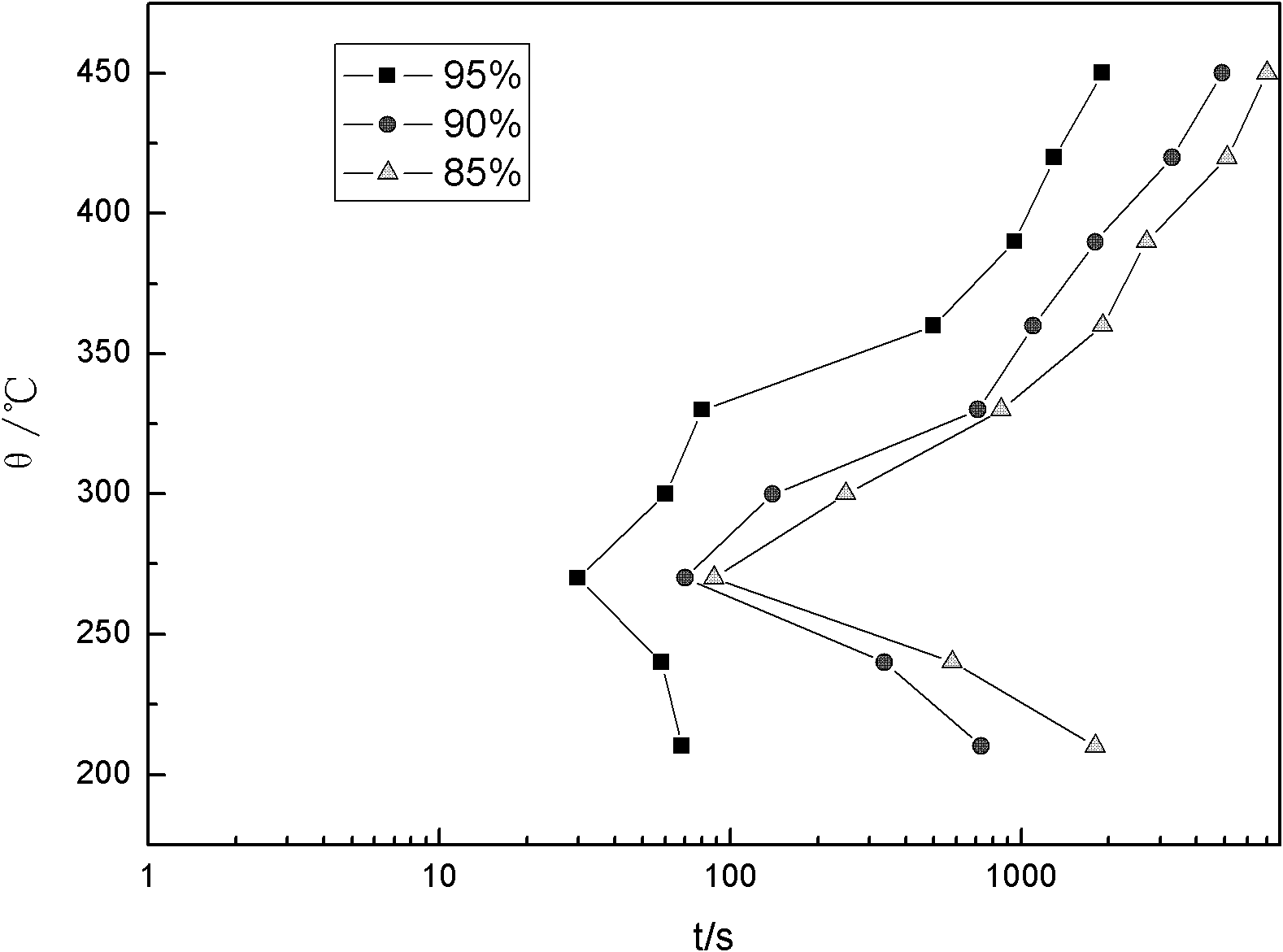

[0037] The alloy composition is 6.5% Zn, 1.4% Mg, 1.3% Cu, 0.13% Zr, 0.08% Ti, 0.1% Ge, the balance is Al, the purity of the Ge is greater than or equal to 99.99%, and it is smelted into an ingot. After homogenization treatment at 450°C / 24h+455°C / 24h, it is hot-rolled into a plate with a thickness of 4mm, and the extrusion ratio is 25. After the sample was solidified at 470°C / 1h, it was quenched in water and air at room temperature, and aged at 120°C / 24h. Tensile property tests show that although the strength of Ge-added alloy samples aged after quenching in room temperature water is lower than that of un-added Ge alloys, the tensile strength of Ge-added alloy samples is higher than that of non-Ge-added alloys when quenched in air 10Mpa, yield strength increased by 99Mpa.

Embodiment 3

[0039] The alloy composition is 7.0% Zn, 1.4% Mg, 1.6% Cu, 0.13% Zr, 0.08% Ti, 0.05% Ge, the balance is Al, the purity of the Ge is greater than or equal to 99.99%, and it is smelted into an ingot. After homogenization treatment at 450°C / 24h+455°C / 24h, it is hot-rolled into a plate with a thickness of 4mm. After the sample was solidified at 470°C / 1h, it was quenched in water and air at room temperature, and aged at 120°C / 24h. Tensile property tests show that although the strength of Ge-added alloy samples aged after quenching in room temperature water is lower than that of the alloy without Ge, when quenched in air, the tensile strength of Ge-added alloy samples is higher than that of the alloy without Ge Increased by 14Mpa, the yield strength increased by 60Mpa. EDS analysis was performed on the precipitated phases of the aluminum alloy treated in this example, and the results are shown in Table 1. The results showed that the precipitated phases were Mg-rich and Ge-rich phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com