Dry ash wetting and recycling technology for desulfurizing sintered fume by rotary spraying and drying method

A technology of rotary spray drying and sintering flue gas, applied in waste heat treatment, combined device, lighting and heating equipment, etc., can solve the problems of high operating cost, long process flow, complex system, etc., to improve desulfurization efficiency and easy process operation. , the effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

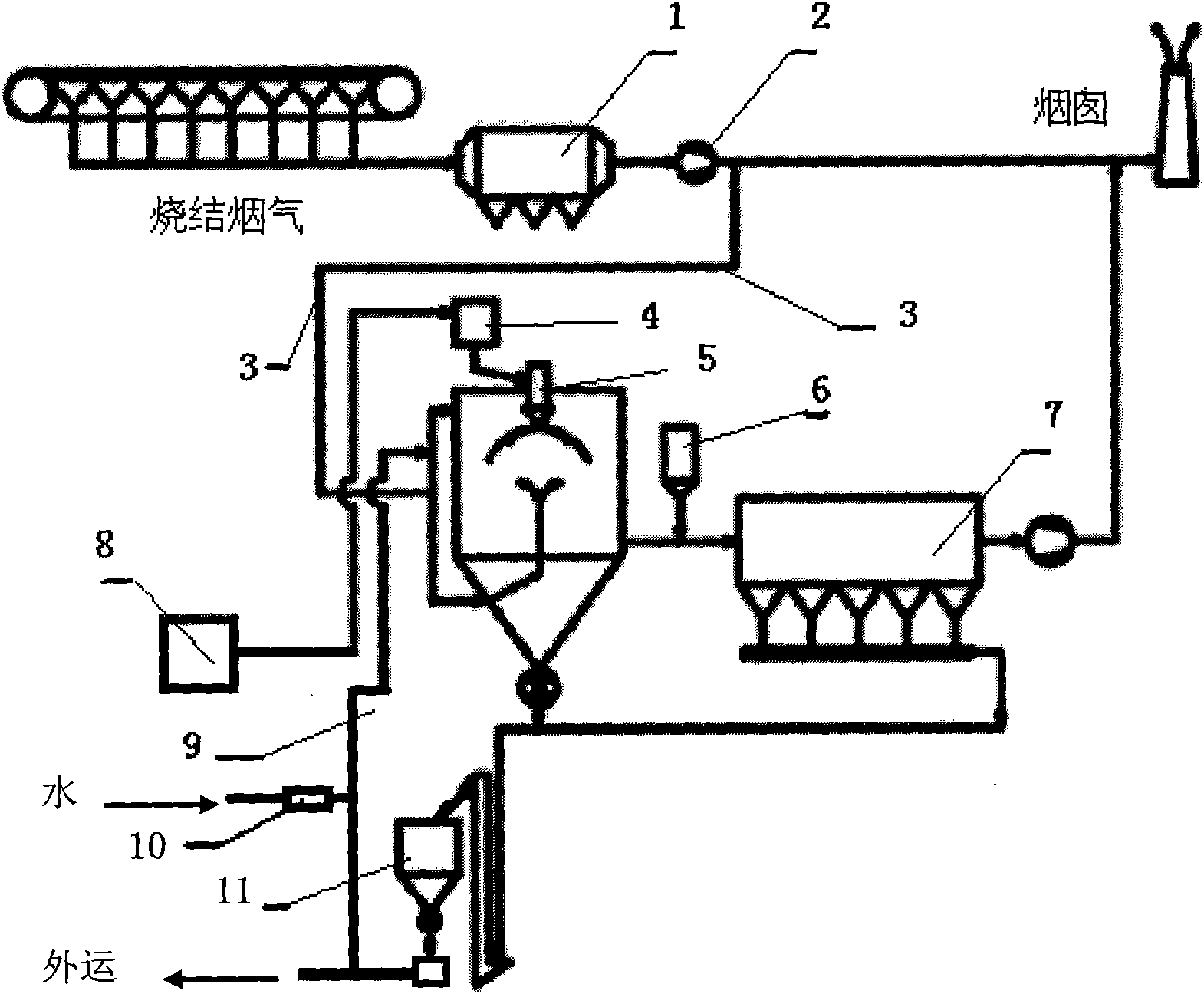

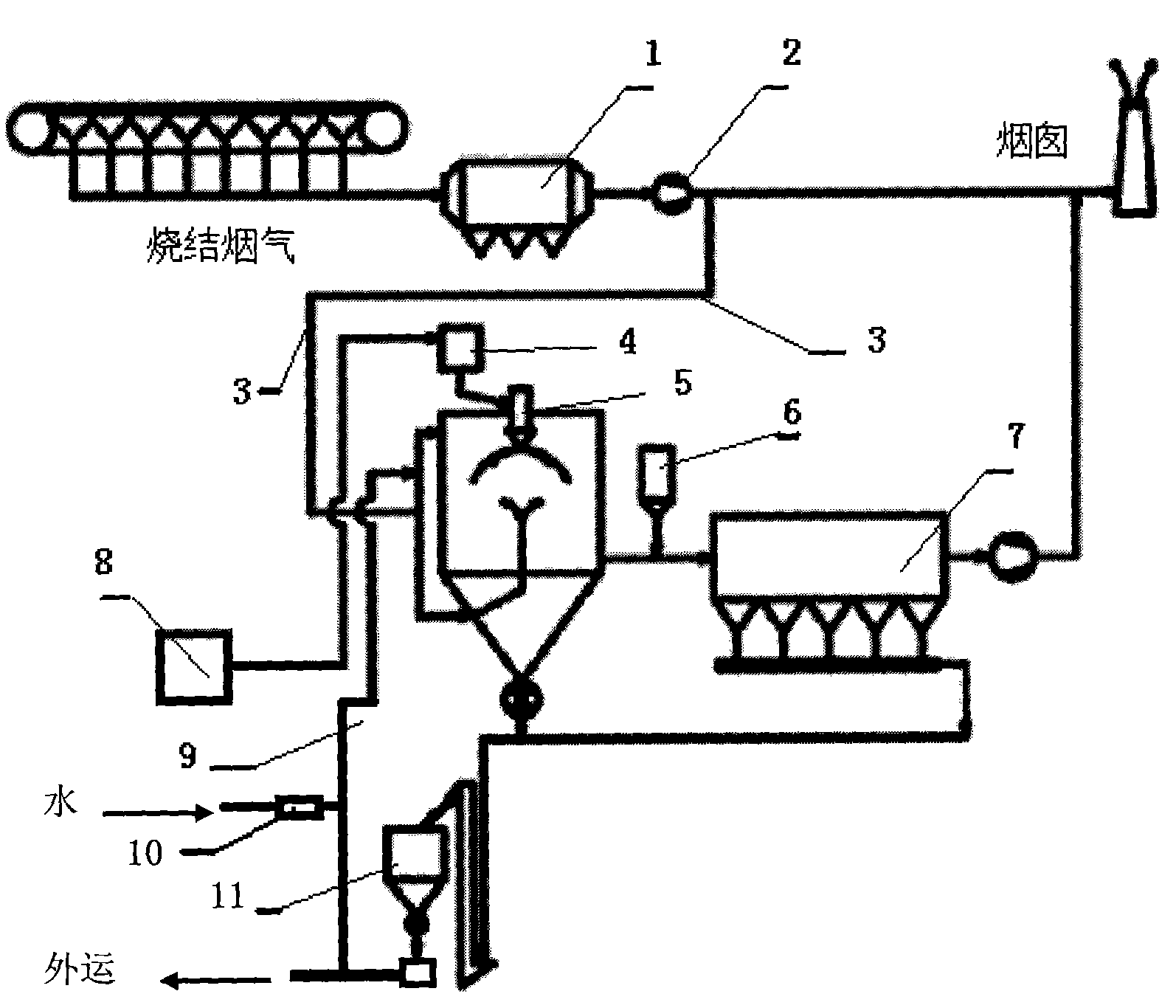

[0010] The process of the present invention will be further described according to the above-mentioned accompanying drawings.

[0011] The lime is prepared into a slurry by the lime slurry preparation device 8 and then pumped to the absorption tower top tank 4 for standby. The wetting water dosing device 10 communicates with the dry ash pipeline 9, and the dry ash pipeline 9 connects the dry ash bin 11 with the flue gas pipeline 3, and the dry ash enters the flue gas pipe after being properly humidified by the wetting water dosing device 10 Road 3 enters the absorption tower after being mixed with flue gas.

[0012] After the sintering flue gas is divided and treated, the low-sulfur flue gas is treated by the electrostatic precipitator 1 and then merged with the clean flue gas discharged from the absorption tower and discharged through the chimney. The high-sulfur flue gas is sent to the absorption tower by the spindle fan 2 through the flue gas pipeline 3, and the dry ash is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com