Preparation method of metal sulfide and carbon composite material and application of metal sulfide and carbon composite material in sodium ion battery

A metal sulfide and composite material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unfavorable sodium ion reversible de-intercalation, small lattice constant, poor electrical conductivity, etc., and is suitable for large-scale development and Application, high specific capacity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

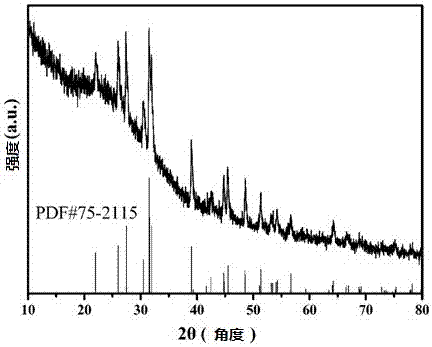

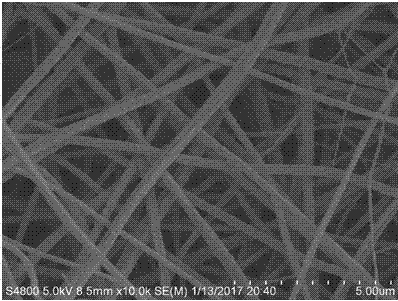

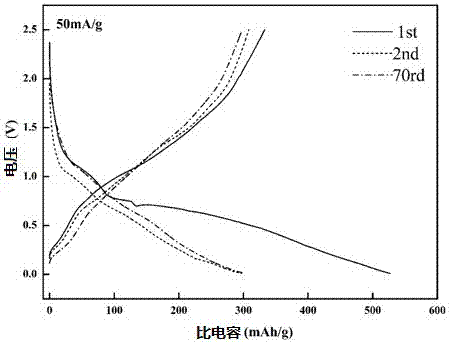

[0032] In this embodiment, an in-situ method is adopted to introduce a sulfur source, and stannous sulfide and a carbon composite material are prepared by electrospinning as a negative electrode material for a sodium ion battery. The specific steps are:

[0033]The metal salt is 0.006mol of tin tetrachloride, the spinning polymer is mixed with 0.65g of polyacrylonitrile and 0.00945mol of L-cysteine and dissolved in 10ml of organic solvent dimethylformamide (DMF), and the mixture is heated at 40°C Under the condition of PH value 6, magnetic stirring for 12 hours, the electrospinning precursor solution was obtained; under the condition of temperature 40 °C and humidity 10%, the precursor solution flowed to the spinning needle at a constant speed of 10 μl / min, and the distance from the needle to the receiver was adjusted to 20cm, under the action of an electrostatic field of 12kV, nanofibers are formed, and the receiver is used to receive the fibers to form spun fiber cloth; the...

Embodiment 2

[0036] In this embodiment, a post-treatment method is adopted to introduce a sulfur source, and a composite material of antimony trisulfide and carbon is obtained by electrospinning as a negative electrode material for a sodium ion battery. The specific steps are:

[0037] 0.01mol of antimony chloride and 0.6g of polyacrylonitrile were mixed and dissolved in 10ml of DMF. The mixture was stirred at 40°C with a pH value of 6 and magnetically stirred for 12 hours to obtain an electrospinning precursor solution; at a temperature of 40°C and a humidity of 10%, Flow the precursor solution to the spinning needle at a constant speed of 10 μl / min, adjust the distance from the needle to the receiver to 20cm, form nanofibers under the action of an electrostatic field of 12kV, and use the receiver to accept the fibers to form spinning fiber cloth; Carry out pre-oxidation in a muffle furnace, the heating rate is 2-10°C / min, the pre-oxidation temperature is 250°C, keep warm for 1h, and cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com