Extrusion dewaterer

A dehydrator and extrusion technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of affecting the efficiency of solid-liquid separation, the variable pitch screw and flow channel space cannot be made too small, blockage, etc., to achieve The effect of low operating cost, simple structure, and high solid-liquid separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

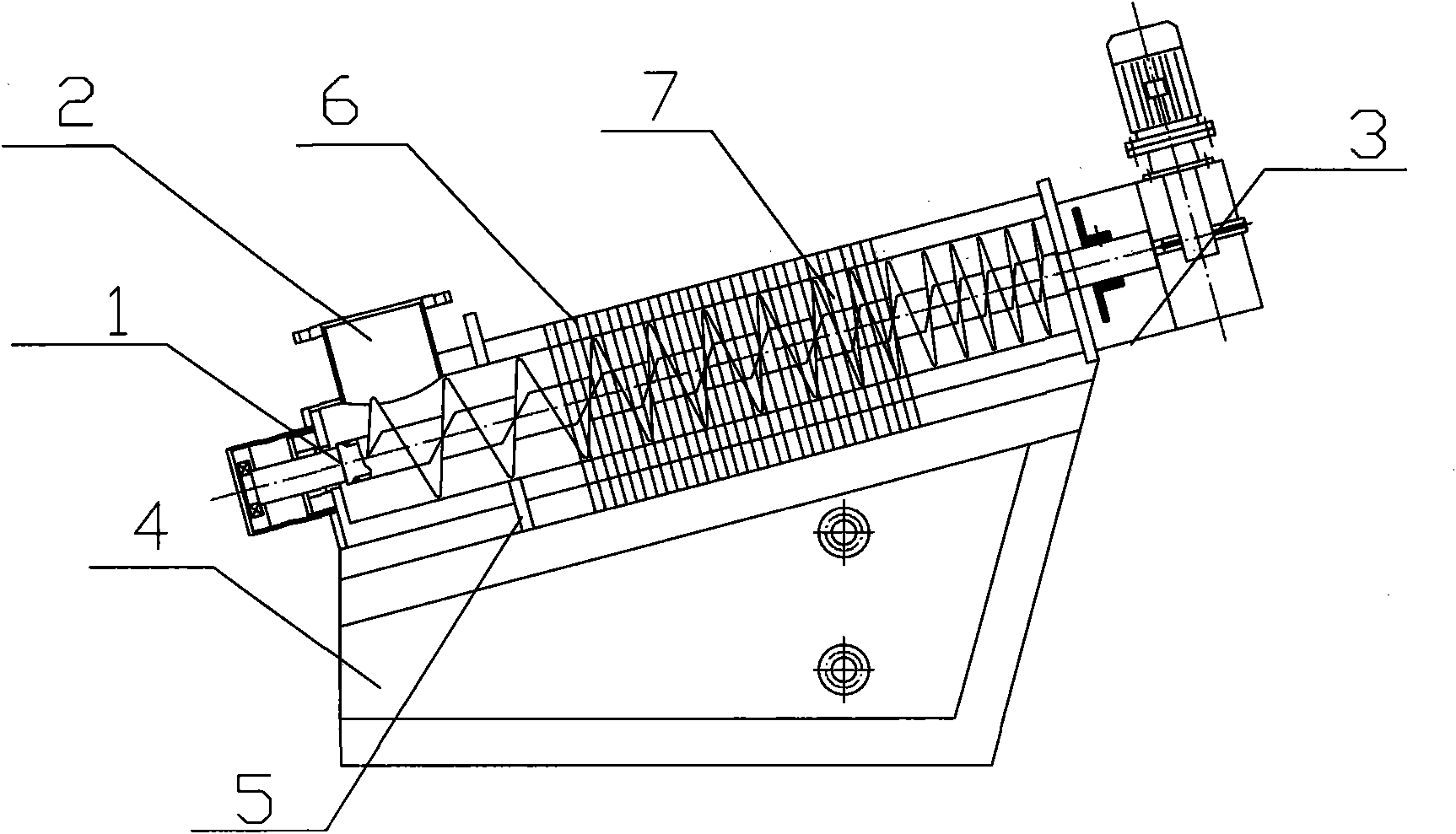

[0015] Such as figure 1 , the extruding dehydrator includes a tunnel-type screw extruder 1 that is inclined. The lower end of the screw extruder 1 is provided with a sludge inlet 2, and the higher end is provided with a mud outlet 3. A water tank 4 is provided, and the water tank 4 communicates with the screw extruder 1 through a water drop hole 5 arranged at the bottom of the tunnel. The inner wall of the tunnel screw extruder 51 is provided with several sets of fixed rings 6 and moving rings 7 that match each other, and the axial gap between the fixed rings 6 and the moving rings 7 is from the sludge inlet to the sludge outlet. The direction gradually becomes smaller. At the same time, the screw pitch of the screw extrusion shaft also gradually decreases from the sludge inlet to the sludge outlet. A pressed plate is provided inside the mud outlet 3 .

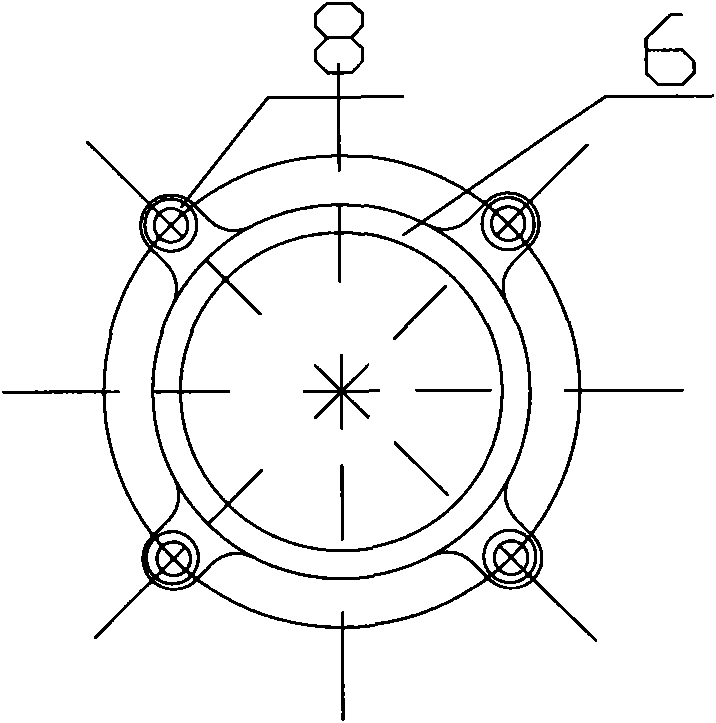

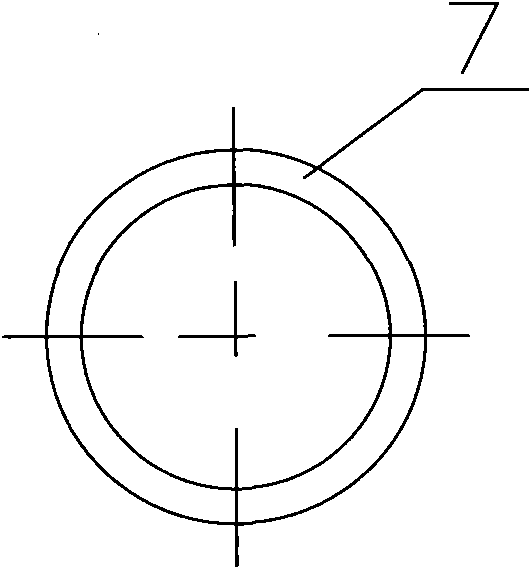

[0016] Such as figure 2 and image 3 As shown, the fixed ring 6 is fixed by four shafts installed on the inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com