High-frequency electric sealing device for solar vacuum tubes and sealing method thereof

A vacuum tube and high-frequency electricity technology, applied in the field of solar vacuum tube processing equipment, can solve the problems of physical and mental health injury, immature technology, frequent operation, etc., and achieve high-frequency heating temperature, easy automatic control, and improve the effect of sealing and separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

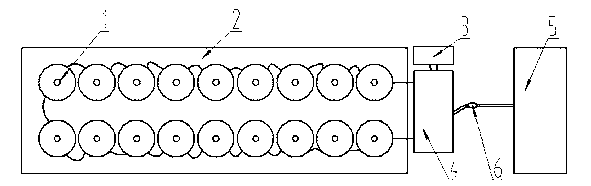

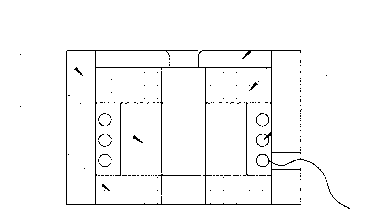

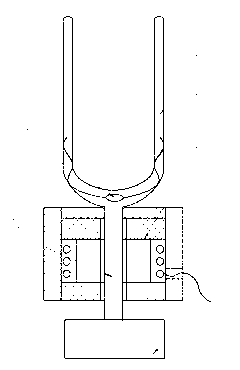

[0029] like figure 1 The solar vacuum tube high-frequency electrical sealing device shown in the figure includes a high-frequency sealing furnace 1 , a sealing table panel 2 , an inductor cooling device 3 , a transformer 4 , and a high-frequency power supply host 5 . The sealing table panel 2 is made of non-conductive, non-magnetic and high-temperature-resistant materials (such as mullite), and a circular fixing hole seat is arranged on its surface for fixing the high-frequency sealing furnace 1 . The high-frequency induction generator 11 of each high-frequency sealing furnace 1 is connected to the transformer 4 in series or in parallel. The high-frequency induction generator 11 and the transformer 4 adopt a set of cooling device, that is, the inductor cooling device 3 . The transformer 4 and the high-frequency power main unit 5 are connected by flexible wires, and there is a quick power connector 6 in the middle of the line, which can realize quick connection and disassembly ...

Embodiment 2

[0034] Taking the processing of solar vacuum tubes 13 as an example to illustrate the process, the exhaust pipe 16 has a diameter of 10-20 mm and a wall thickness of 1-3 mm. The high-frequency induction generator 11 and vacuum equipment 17 seal off 30 solar vacuum tubes 13 in total. Operation, the height of the induction heating body 10 is 10-15mm, the inner diameter is 12-22mm and the outer diameter is 40-50mm, and the thickness of the upper insulation board 9 is 10-18mm.

[0035] The present invention is not limited to processing glass exhaust pipes of such specifications, and the sealing and separating process described in the present invention is applicable to the sealing and separating operation of all glass vacuum pipe exhaust pipes, and the number of stations is adjustable.

[0036] The high-frequency sealing and separating process of the vacuum tube exhaust pipe of the present invention, the specific operation steps are as follows:

[0037] (1) The solar vacuum tube 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com