Benzoic acid modified waterborne alkyd resin and amino plastic baking varnish prepared by same

A water-based alkyd resin, alkyd amino technology, applied in coatings, polyester coatings, etc., can solve the problems of limited use range, poor hardness, low gloss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

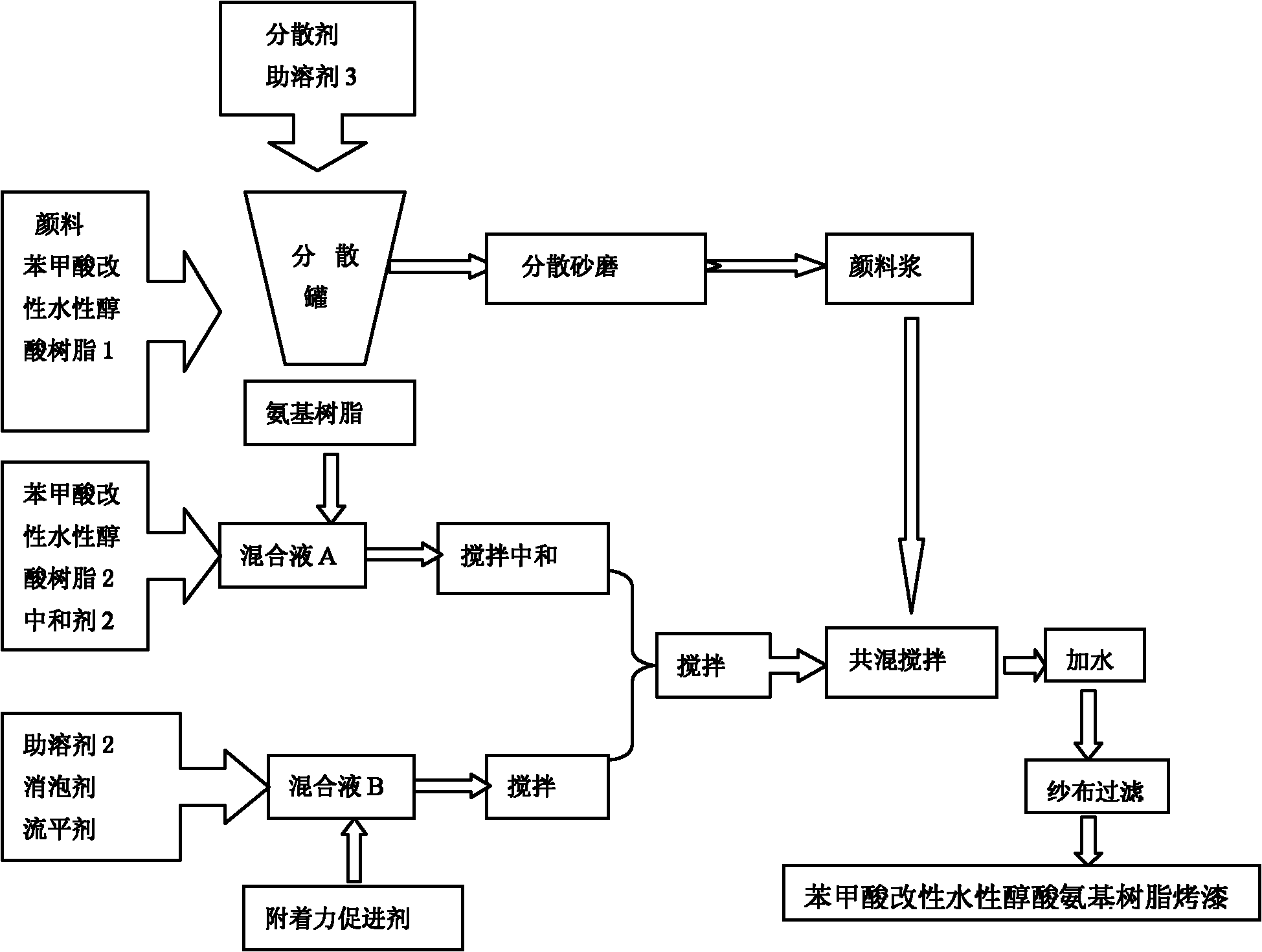

Image

Examples

Embodiment 1

[0080] A, preparation of benzoic acid modified water-based alkyd resin:

[0081] 26g of castor oil and 30.1g of trimethylolpropane were heated to 180°C for 1.5h under nitrogen protection, and then 24.5g of isophthalic anhydride, 6g of benzoic acid and 0.007g of terephthalic acid esterification catalyst were added ( Esterification catalyst 4100) produced by Guangzhou Zhiyi Trading Co., Ltd., and install a water separator, continue heating to 220°C, keep warm for reaction, track and monitor the acid value of the reaction system, until the acid value of the system is as low as 10mgKOH / g, cool down to 150°C , add 8g of trimellitic anhydride, keep warm at 170°C until the acid value is 55mgKOH / g, cool down to 100°C, remove the water separator and nitrogen, add 28g of ethylene glycol monobutyl ether, 11g of triethylamine, and react for 0.5 h made benzoic acid modified water-based alkyd resin 120g, sealed and kept for later use.

[0082] B, prepare benzoic acid modified water-based a...

Embodiment 2

[0102] Preparation method and step are with embodiment 1, difference is, the raw material consumption of preparing benzoic acid modified water-based alkyd amino resin baking varnish in step B is as follows:

[0103] Pigment paste:

[0104] Benzoic acid modified water-based alkyd resin 50g

[0105] Iron red 30g

[0106] BYK-190 1.5g

[0107] Ethylene glycol monobutyl ether 18.5g

[0108] Benzoic acid modified water-based alkyd amino resin baking varnish:

[0109] Benzoic acid modified water-based alkyd resin 24.5g

[0110] Pigment paste 18.8g

[0111] Hexamethoxymelamine resin 7.4g

[0112] Triethylamine 2g

[0113] W-100 1.8g produced by BSK

[0114] Ethylene glycol monobutyl ether 15.2g

[0115] BYK-346 0.2g

[0116] BYK-024 0.1g

[0117] water 30g

[0118] Other operations and conditions were the same as in Example 1 to obtain 100 g of benzoic acid modified water-based alkyd amino resin baking varnish.

Embodiment 3

[0120] Preparation method and step are with embodiment 1, difference is, the raw material consumption of preparing benzoic acid modified water-based alkyd amino resin baking varnish in step B is as follows:

[0121] Pigment paste:

[0122] Benzoic acid modified water-based alkyd resin 50g

[0123] Everlasting Yellow 20g

[0124] Ethylene glycol monobutyl ether 29.2g

[0125] BYK-190 0.8g

[0126] Benzoic acid modified water-based alkyd amino resin baking varnish:

[0127] Benzoic acid modified water-based alkyd resin 14.4g

[0128] Pigment paste 31.5g

[0129] Hexamethoxymelamine resin 6.7g

[0130] Triethylamine 2g

[0131] W-100 2.6g produced by BSK

[0132] Ethylene glycol monobutyl ether 12.5g

[0133] BYK-346 0.2g

[0134] BYK-024 0.1g

[0135] water 30g

[0136] Other operations and conditions were the same as in Example 1 to obtain 100 g of benzoic acid modified water-based alkyd amino resin baking varnish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com