Road repairing and building asphalt mixture warm-mixing additive, preparation method thereof and using method thereof

A kind of asphalt mixture and additive technology, which is applied in building insulation materials, buildings, roads, etc., can solve the problems of high cost, complicated production, and no substantial progress, so as to improve the bonding state, strengthen the adhesion, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

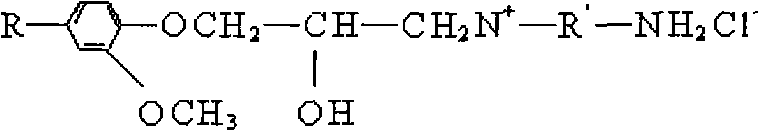

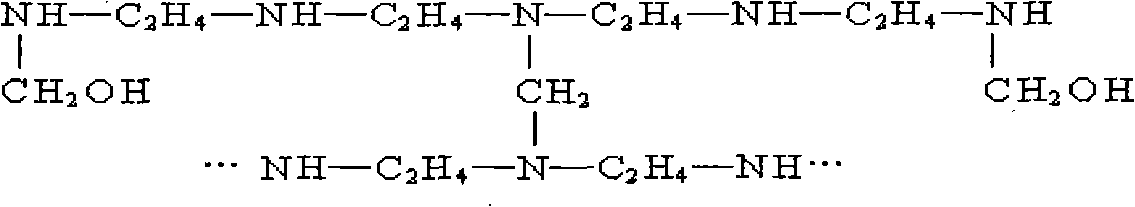

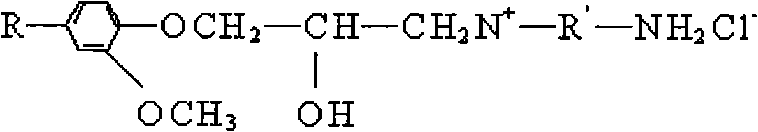

Method used

Image

Examples

Embodiment 1

[0030] Put 30 grams of lignin and 6 grams of epichlorohydrin into the reaction kettle, start stirring and raise the temperature to 75°C for 2 hours, the reaction pressure rises to 0.15MPa, then add 51 grams of tallow diamine, and then heat up to 150°C for reaction 3 After 1 hour, the temperature was raised to 180° C. for 2.5 hours, and then the temperature was raised to 220° C. for 3 hours. The reactant was cooled to 70° C. and discharged to obtain lignin amine salt. Take 30 grams of the obtained lignin amine salt and add 210 grams of industrial water into the dissolving equipment, and stir and dissolve at a temperature of 54-56°C. Then 10.9 grams of octylphenol polyoxyethylene ether (OP-10, 70% content), 0.08 grams of amine anti-stripping agent, and 10 grams of hydrochloric acid with a mass concentration of 37% are added to the dissolution equipment successively, and stirred After uniformity, 260.98 grams of warm mix additives for asphalt mixture were prepared.

Embodiment 2

[0032] The other operating conditions of this embodiment are the same as in Example 1, except that decyl diamine is used instead of tallow diamine, and the amount of decyl diamine is 43.4 grams.

Embodiment 3

[0034] Other operating conditions of this embodiment are the same as in Example 1, except that m-phenylenediamine is used instead of tallow diamine, and the amount of m-phenylenediamine is 33.5 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com