C.i. pigment red 112 with improved dispersion

A pigment red, dispersing technology, applied in organic dyes, azo dyes, household appliances, etc., can solve problems such as performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1.1) Preparation of the diazonium salt solution of 2,4,5-trichloroaniline:

[0047] 250 parts of water were previously added and at room temperature first 40.3 parts of 2,4,5-trichloroaniline were added with stirring and admixed with 193 parts by volume of 31% strength hydrochloric acid. It was then cooled to 0°C with ice. The diazotization was carried out with 29 parts by volume of a 40% strength sodium nitrite solution. The diazonium salt solution formed is filtered off into a receiving vessel after addition of a clarification aid. Excess nitrite was removed by adding sulfamic acid and the temperature was maintained at 10°C by external cooling.

[0048] 1.2) Preparation of a solution of the coupling component (naphthol):

[0049] At room temperature, 190 parts of water and 28 parts by volume of 33% sodium hydroxide solution, and 1 part of alkylsulfonate were pre-added, and 60 parts of N-(2-methylphenyl)-2-hydroxy-3 - Naphthamide. The mixture was stirred until a c...

Embodiment 2

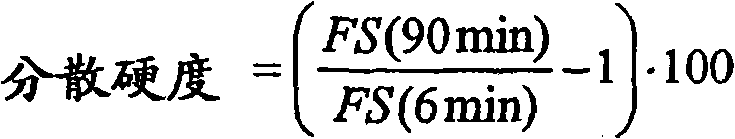

[0057] The synthesis was carried out as described in Example 1, where step 1.3) was followed by grinding the precipitated coupler via a Dispax mill. The dispersion hardness is 25, the residual coupler content is 0.69%, and the polychlorinated biphenyl content is 3ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com