Metal copper powder film coating equipment and coating method

A technology of thin film coating and copper powder, which is applied in the coating process and coating of metal materials, which can solve the problems of uneven coating, time-consuming and labor-intensive production, and cost of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

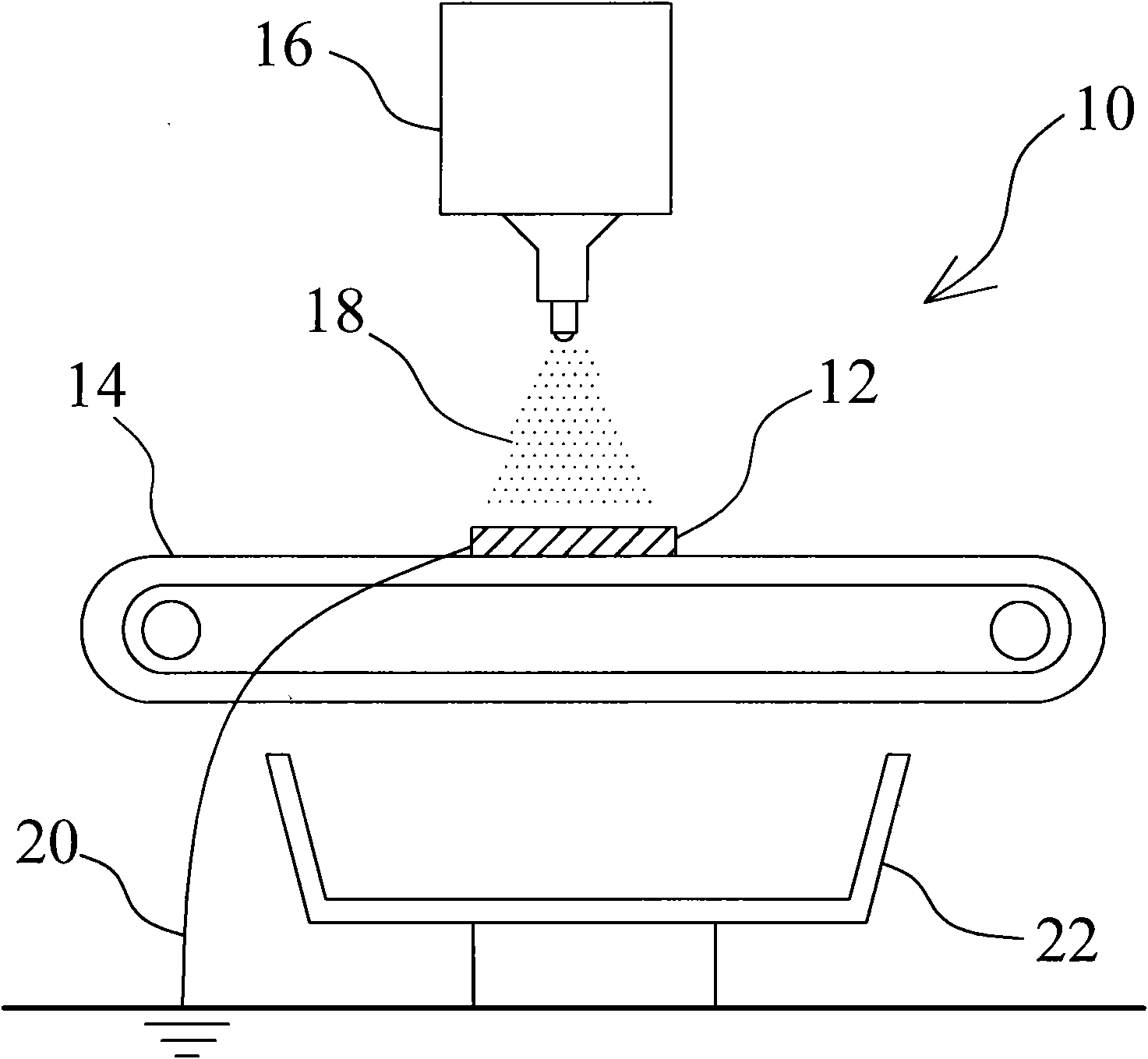

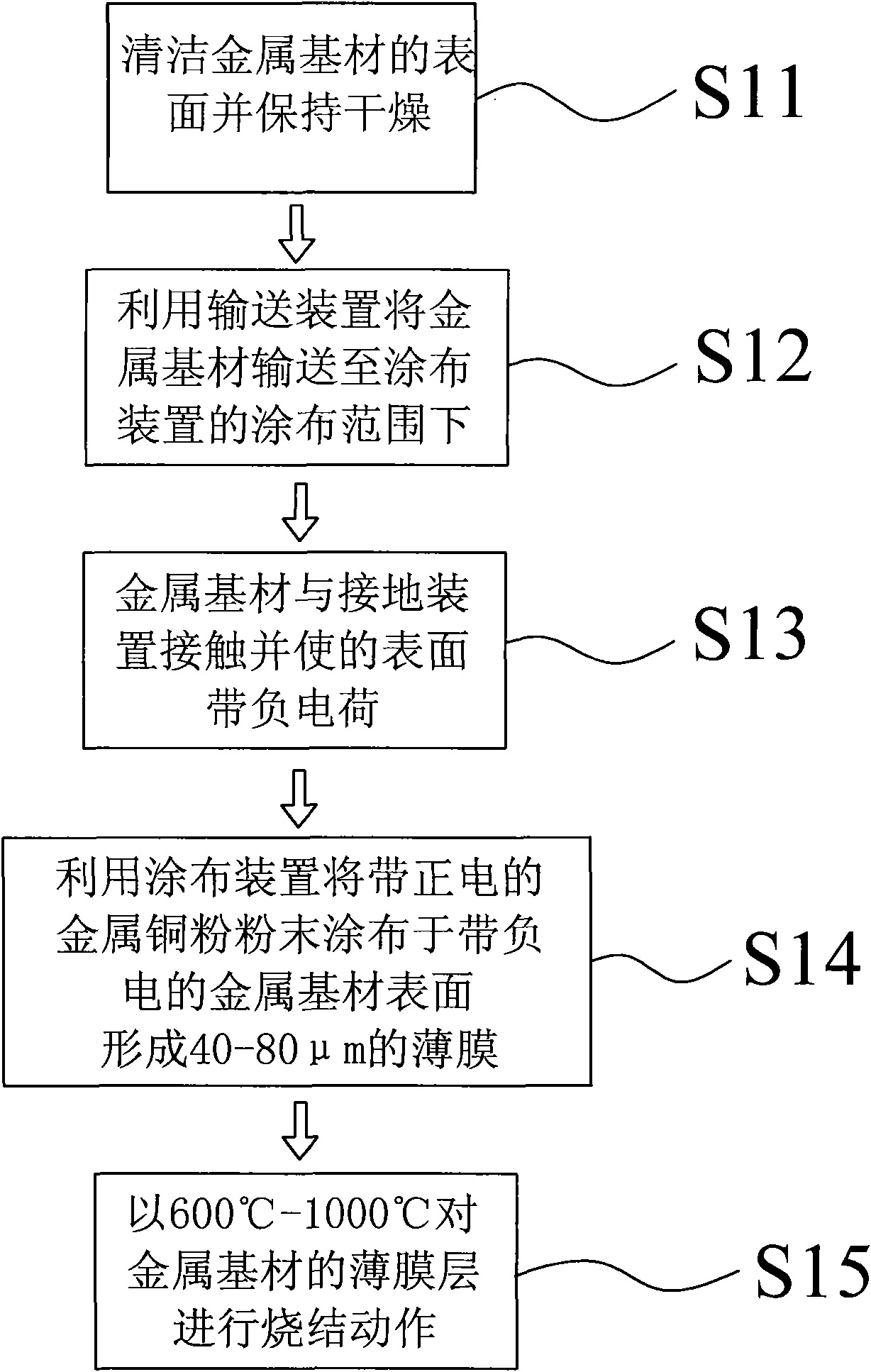

[0012] figure 1 It is a schematic structural view of the metal copper powder film coating equipment of the present invention, as shown in the figure, a metal copper powder film coating equipment 10 is mainly used for the film coating operation of the metal base material 12 of the cooling plate, and the metal base material 12 is copper Material, the metal substrate 12 needs to go through the surface cleaning step before coating. The surface cleaning step uses pure water grade or ultrapure water grade to minimize the particles and impurities in the coating environment and keep the overall coating environment dry . Metal copper powder film coating equipment 10 of the present invention comprises a conveying device 14, can convey metal base material 12, and conveying device 14 is a conveyor belt; A coating dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com