Device and method for preparing magnesium oxide-based film with high secondary emission performance

An oxide film and thin film technology, applied in sputtering coating, vacuum evaporation coating, ion implantation coating and other directions, can solve the problems of poor resistance to electron/ion beam bombardment, unstable emission performance, limited composition control and so on , to achieve the effect of good secondary emission performance, stable secondary emission performance and adjustable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

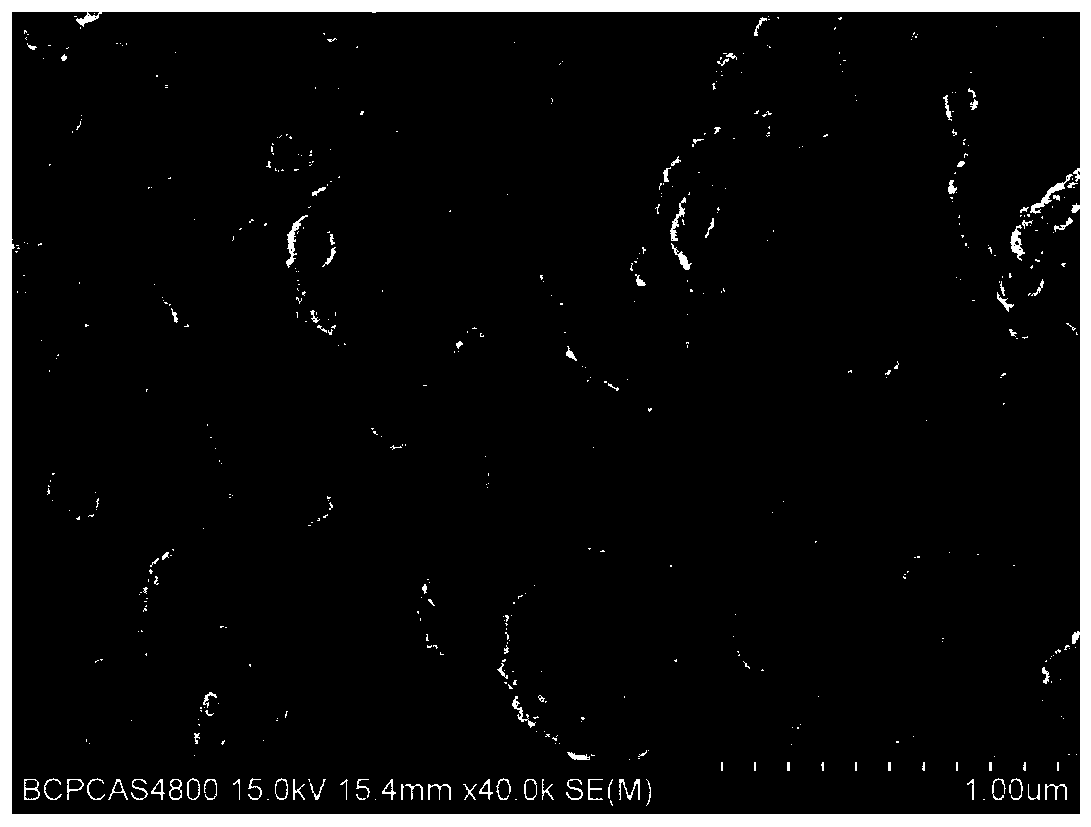

Embodiment 1

[0041] Weigh about 0.4g of high-purity magnesium particles, clean the surface according to the above method, and place it on the tungsten boat of the evaporation source in the vacuum chamber of the thermal evaporation apparatus. The tungsten boat is covered with a pure tungsten mesh. The flap above the tungsten boat remains closed. Adhere the cleaned FTO glass to the stainless steel substrate, and then place the substrate upside down on the sample holder. The vertical distance between the FTO glass to be evaporated and the evaporation source tungsten boat below it is 20 cm. Close the vacuum chamber door of the evaporation apparatus, and evacuate to 9.8×10 -4 Pa, turn on the evaporation power switch, adjust the current to 90A for 2min, and preheat the material to be evaporated. At the same time, the sample stage was turned on to rotate at 20 r / min. Increase the current to 110A, and open the flap above the tungsten boat, and stop loading the current after 2 minutes of thermal...

Embodiment 2

[0043] Weigh about 0.4g of high-purity magnesium particles, and clean the surface according to the above method. Weigh 0.4g of high-purity zinc wire, wind it into a roll, and place it and magnesium particles on two evaporation source tungsten boats in the vacuum chamber of the thermal evaporation apparatus, and cover the tungsten boats where the magnesium particles are located with pure tungsten mesh. The flaps above the two tungsten boats remain closed. Adhere the cleaned silicon wafer to the stainless steel substrate, and then place the substrate upside down on the sample holder. The vertical distance between the silicon wafer to be evaporated and the evaporation source tungsten boat below it is 20 cm. Close the vacuum chamber door of the evaporation apparatus, and evacuate to 9.8×10 -4 Pa, turn on the evaporation power switch, adjust the current to 90A for 2min, and preheat the material to be evaporated. At the same time, the sample stage was turned on to rotate at 20 r / ...

Embodiment 3

[0045] Weigh about 0.4g of high-purity magnesium particles, and clean the surface according to the above method. Weigh 0.4g of high-purity aluminum wire, polish the surface with 2000# sandpaper, clean it with ethanol, dry it with cold air, and wind it into a roll. Magnesium grains and aluminum wires are respectively placed on two evaporation source tungsten boats in the vacuum chamber of the thermal evaporation apparatus, and the tungsten boats where the magnesium grains are located are covered with pure tungsten mesh. The flaps above the two tungsten boats remain closed. Adhere the cleaned silicon wafer to the stainless steel substrate, and then place the substrate upside down on the sample holder. The vertical distance between the silicon wafer to be evaporated and the evaporation source tungsten boat below it is 20 cm. Close the vacuum chamber door of the evaporation apparatus, and evacuate to 9.8×10 -4 Pa, turn on the evaporation power switch, adjust the current to 90A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com