PU double-component multifunctional undercoat and preparation method thereof

A multi-functional, two-component technology, which is applied in the field of primer coatings and PU two-component multi-functional primers, can solve the problems of affecting product appearance, low surface gloss, and prone to scratches, etc., to achieve increased protection Excellent durability, scratch resistance, and excellent functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

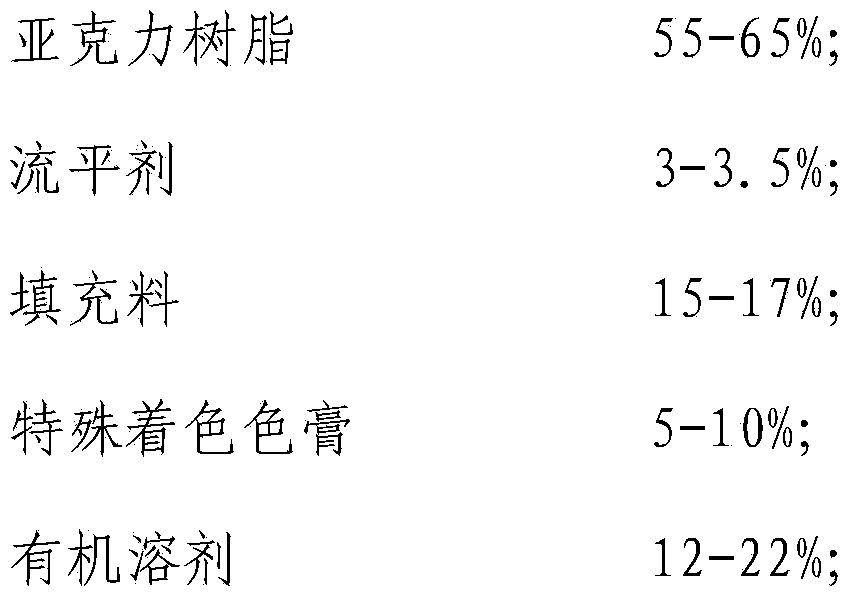

[0037] Example 1: After mixing the acrylic resin, 3% inorganic nano-denatured oligomer, 22% organic solvent, and 15% aluminum potassium silicate, which are respectively 55% by mass, they are dispersed at a high speed, and then ground, Wherein the grinding temperature is lower than 60 degrees, and after the grinding is completed, a special coloring paste with a mass percentage content of 5% is added for color blending.

Embodiment 2

[0038] Example 2: Mix the acrylic resin, 3% inorganic nano-denatured oligomer, 12% organic solvent, and 15% aluminum potassium silicate in mass percentages of 65% and then disperse at a high speed, and then grind, Wherein the grinding temperature is lower than 60 degrees, and after the grinding is completed, the mass percentage is 5% by adding a special coloring paste for color blending.

Embodiment 3

[0039] Example 3: Mix the acrylic resin, 3.5% inorganic nano-denatured oligomer, 13% organic solvent, and 15.5% potassium aluminum silicate with a mass percentage content of 60% respectively, and then perform high-speed dispersion, and then grind, Wherein the grinding temperature is lower than 60 degrees, and after the grinding is completed, the mass percentage is 8% by adding a special coloring paste for color blending.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com