Method for preparing antimony tetrasulfide tricopper film of solar cell absorption layer through gas-solid reaction

A solar cell and gas-solid reaction technology, applied in coatings, circuits, electrical components, etc., can solve the problems of increased process difficulty due to selective deposition characteristics and difficulty in effectively controlling components, so as to achieve less strict control conditions and lower operating costs. The effect of difficult process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

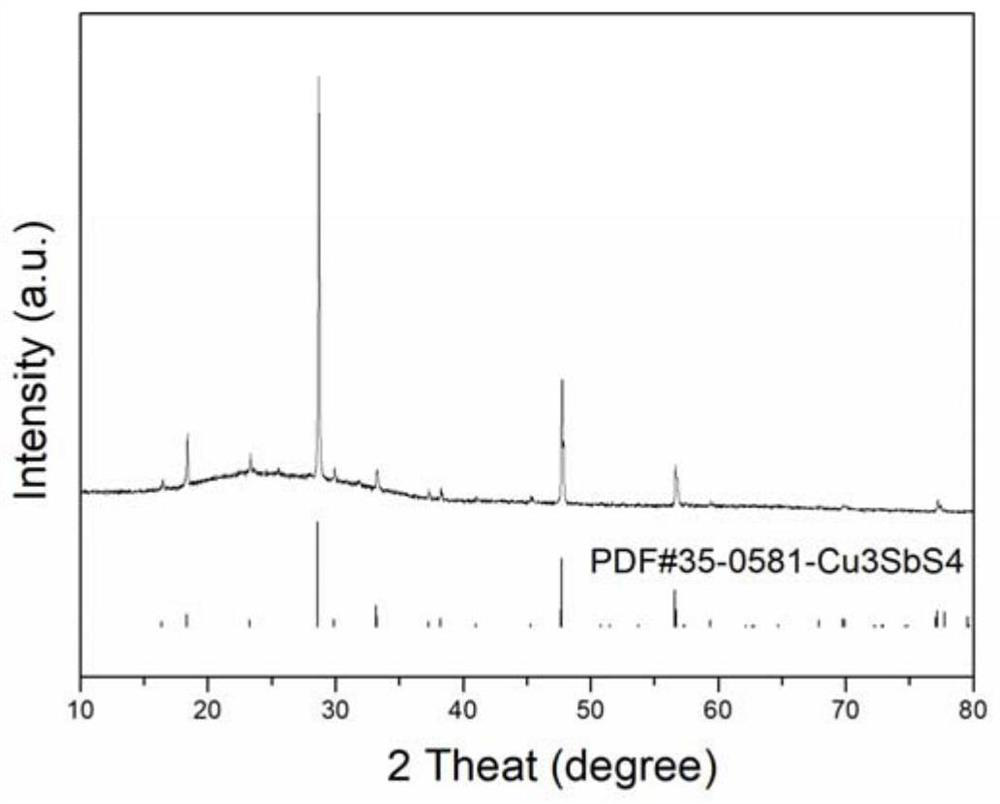

Image

Examples

Embodiment 1

[0026] Preparation of solar cell absorber layer Cu by a gas-solid reaction 3 Sb 4 thin film method

[0027] 1. First, clean the glass substrate: immerse the glass substrate in detergent, acetone, ethanol and deionized water solution for ultrasonic cleaning, and then dry it to obtain a clean glass substrate;

[0028] 2. Place the cleaned glass substrate in the magnetron sputtering studio;

[0029] 3. Use the magnetron sputtering coating system to pump the background vacuum of the sputtering system to less than 10 -4 Pa;

[0030] 4. Sputtering gas Ar bombards the target through the magnetron sputtering coating machine,

[0031] The sputtering gas uses argon with a purity of 99.9%;

[0032] The target material adopts a copper target with a purity of 99.8%;

[0033] The working air pressure in the magnetron sputtering studio is 0.3Pa;

[0034] 5. The setting parameters are: power: 120W; gas flow: 60sccm; deposition time: 2h;

[0035] 6. The sputtered copper is attached to ...

Embodiment 2

[0039] Preparation of solar cell absorber layer Cu by a gas-solid reaction 3 Sb 4 thin film method

[0040] 1. First, clean the glass substrate: immerse the glass substrate in detergent, acetone, ethanol and deionized water solution for ultrasonic cleaning, and then dry it to obtain a clean glass substrate;

[0041] 2. Place the cleaned glass substrate in the magnetron sputtering studio;

[0042] 3. Use the magnetron sputtering coating system to pump the background vacuum of the sputtering system to less than 10 -4 Pa;

[0043] 4. Sputtering gas Ar bombards the target through the magnetron sputtering coating machine,

[0044] The sputtering gas uses argon with a purity of 99.9%;

[0045] The target material adopts a copper target with a purity of 99.8%;

[0046] The working air pressure in the magnetron sputtering studio is 0.3Pa;

[0047] 5. The setting parameters are: power: 60W; gas flow: 60sccm; deposition time: 2h;

[0048] 6. The sputtered copper is attached to t...

Embodiment 3

[0051] 1. First, clean the glass substrate: immerse the glass substrate in detergent, acetone, ethanol and deionized water solution for ultrasonic cleaning, and then dry it to obtain a clean glass substrate;

[0052] 2. Place the cleaned glass substrate in the magnetron sputtering studio;

[0053] 3. Use the magnetron sputtering coating system to pump the background vacuum of the sputtering system to less than 10 -4 Pa;

[0054] 4. Sputtering gas Ar bombards the target through the magnetron sputtering coating machine,

[0055] The sputtering gas uses argon with a purity of 99.9%;

[0056] The target material adopts a copper target with a purity of 99.8%;

[0057] The working air pressure in the magnetron sputtering studio is 0.3Pa;

[0058] 5. The setting parameters are: power: 75W; gas flow: 60sccm; deposition time: 0.5h;

[0059] 6. The sputtered copper is attached to the substrate, and the thickness of the Cu film is 100nm;

[0060] 7. Use the Cu precursor film obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com