Active reflection compensation servo-type single-board wave making device

A wave-making device and compensating technology, which is applied in measuring devices, fluid dynamics tests, and machine/structural component tests, etc., can solve problems such as low control accuracy, wave environment simulation distortion, and high cost, and simplify the drive mechanism , Improve the frequency response, improve the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

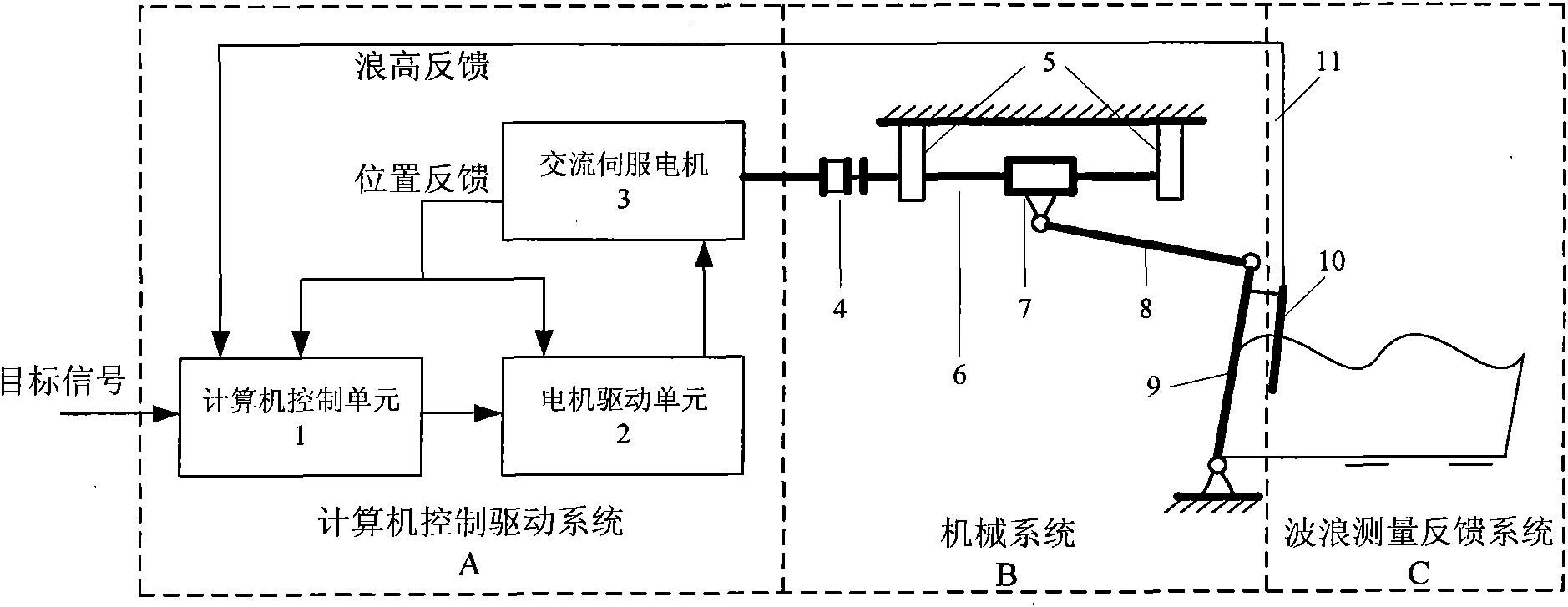

[0018] Such as figure 1 As shown, the present invention includes a computer-controlled drive system A, a mechanical system B and a wave measurement feedback system C connected in sequence.

[0019] See figure 1 , The computer-controlled drive system A is composed of a computer control unit 1, a motor drive unit 2 and an AC servo motor 3. The computer control unit 1 receives the target signal, drives the AC servo motor 3 through the motor drive unit 2, the AC servo motor 3 transmits the kinetic energy to the mechanical system B, and feeds back the position signal to the computer control unit 1 and the motor drive unit 2, and the computer control unit 1 Simultaneously receive the wave height feedback signal from the wave measurement feedback system C.

[0020] See figure 1 , Mechanical system B is composed of coupling 4, bearing 5, screw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com