Intelligent fault diagnosis system in tread extrusion process and diagnosis method thereof

A fault diagnosis system and fault diagnosis technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem of taking a lot of time to find faults, achieve the effects of reducing labor intensity, practical structure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

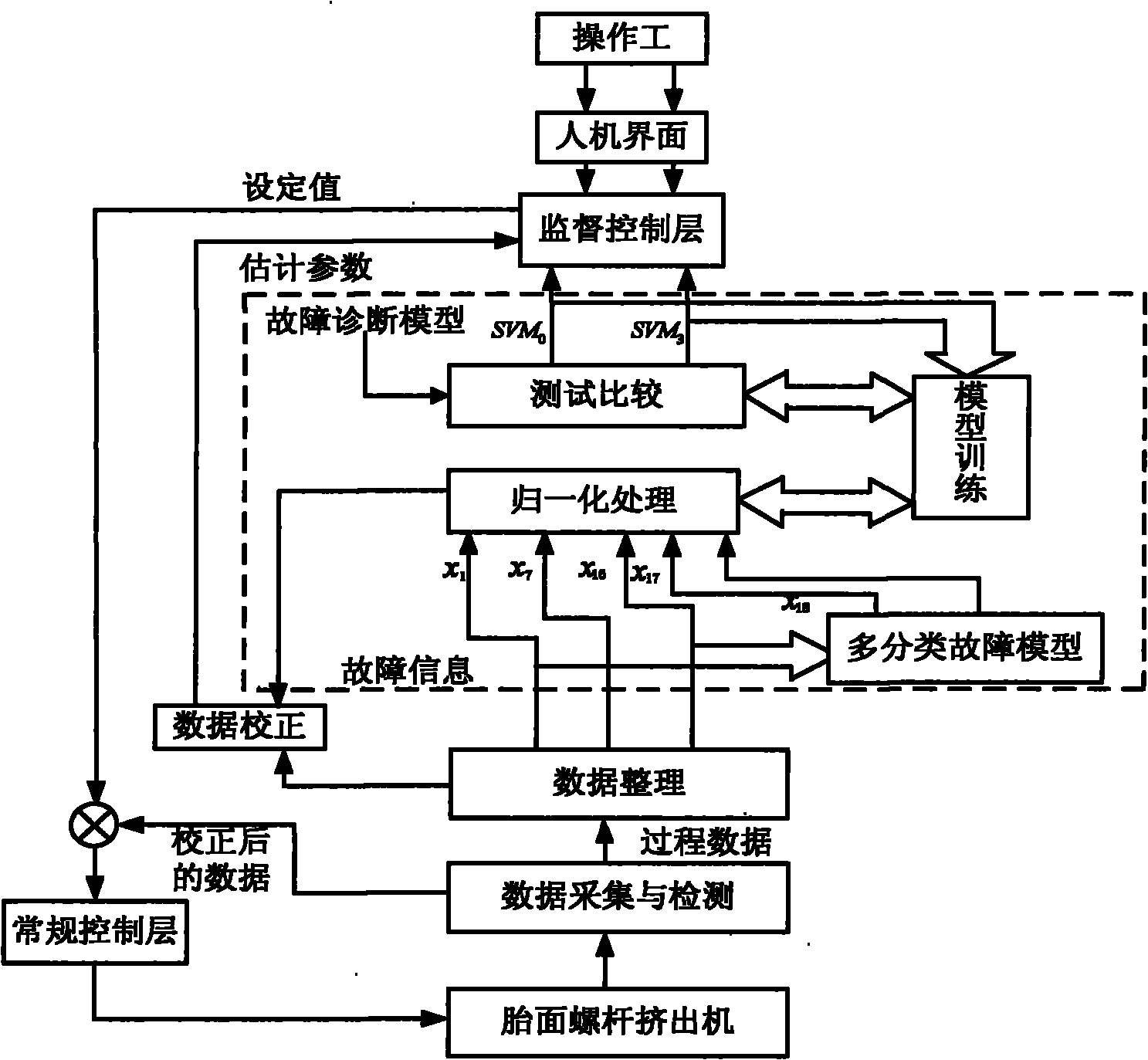

[0010] The fault diagnosis system of the present invention realizes the connection with the field equipment through the PLC control network; uses the digital technology to combine the physical manufacturing system into an information-based system to make it operate effectively; at the same time, realizes the equipment status monitoring with the help of multimedia audio-visual technology for diagnosis and control. Therefore, fault diagnosis has practical significance for the reliable, continuous and safe production of tread extrusion production process.

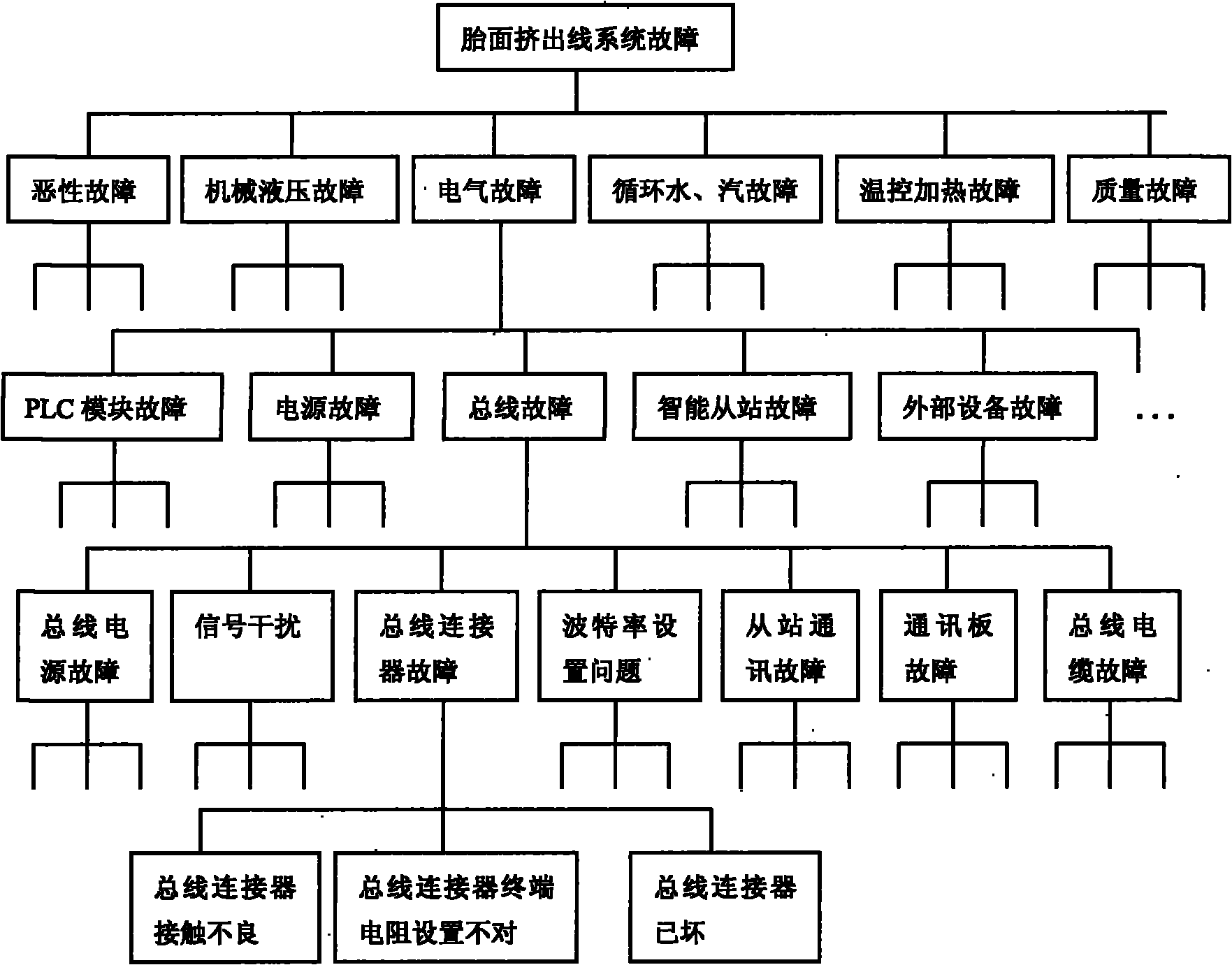

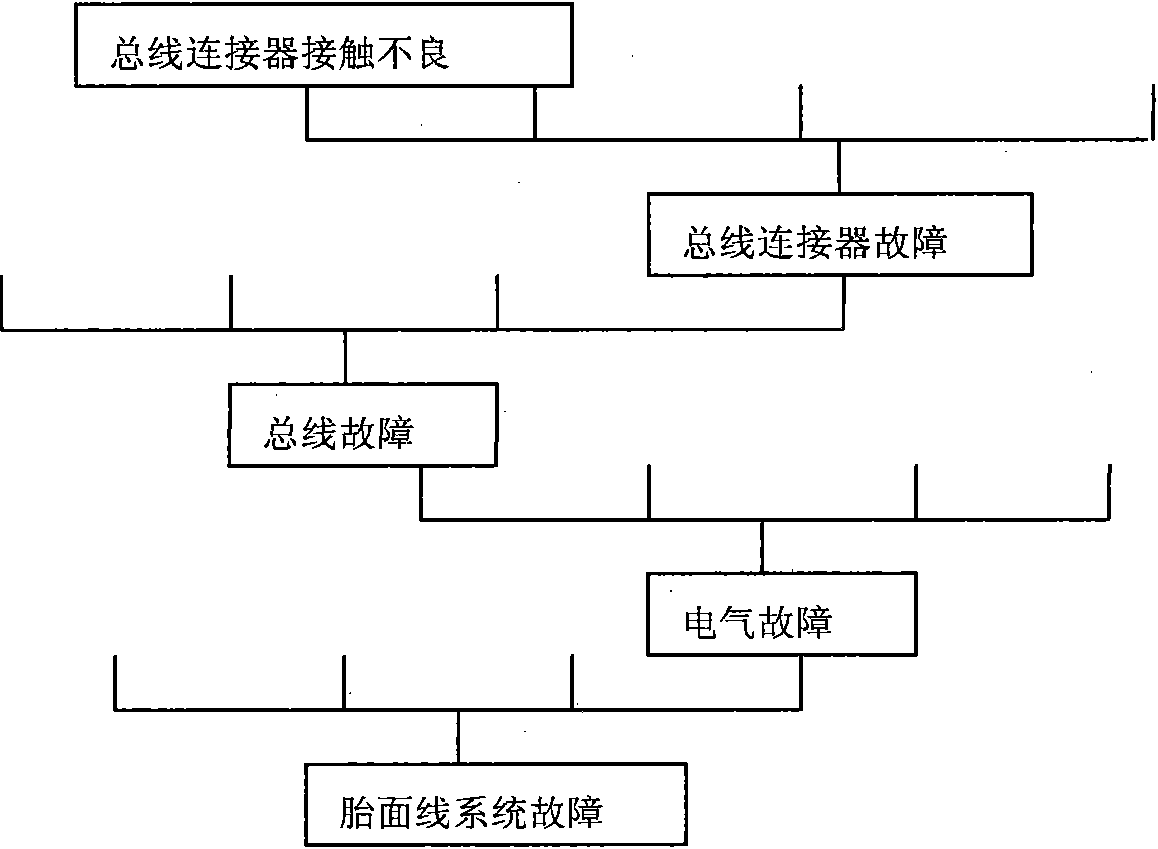

[0011] The present invention establishes a tree-shaped fault model aiming at external equipment faults, intelligent slave station faults, PLC system faults, and bus faults of the control system of the tread extrusion production line, and uses the above-mentioned faults as the root node of the upper-end event tree to directly generate system faults. The reason is used as the branch node of the lower-end event (intermediate even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com