Preparation method of high-activity segregative TiO2 photocatalyst

A photocatalyst and easy-separation technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low catalytic efficiency of photocatalysts, insufficient firmness of stationary phase, and limited practical use. Achieve the effect of wide application, easy separation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

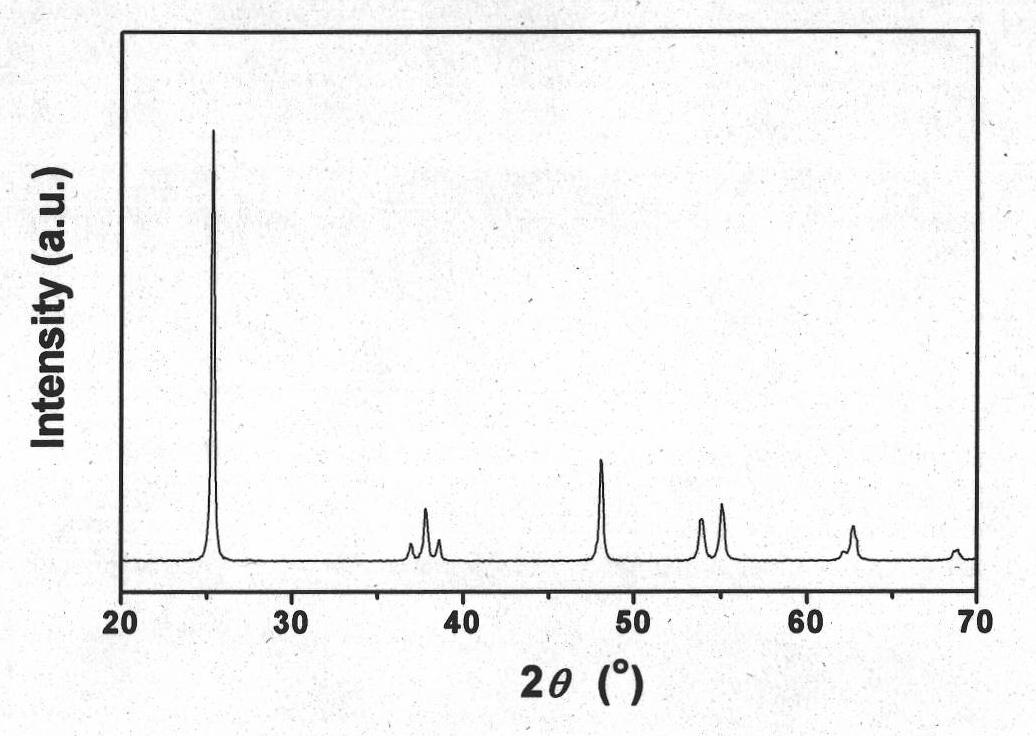

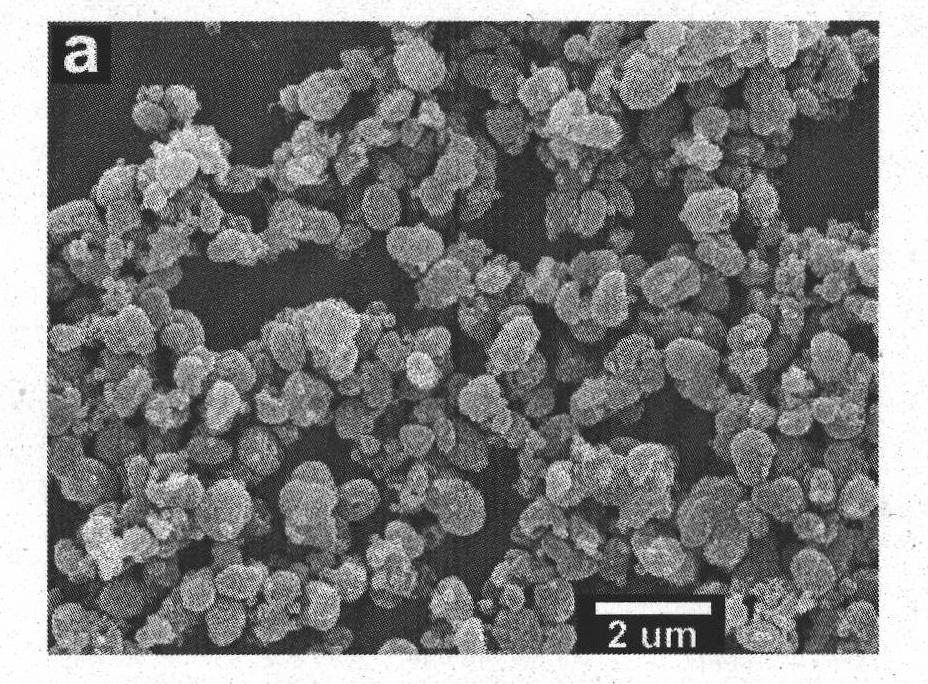

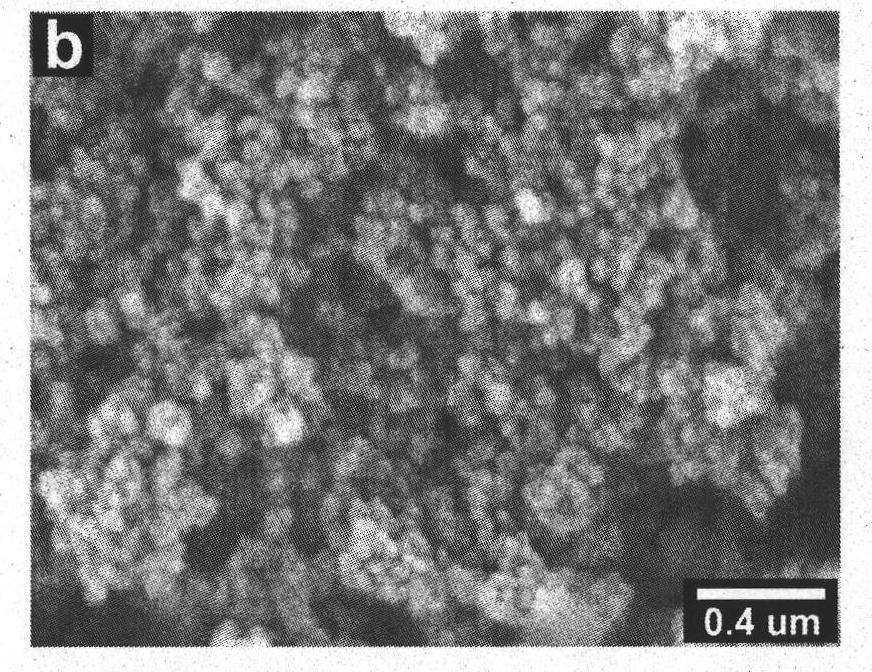

[0028] Take by weighing 5.4g urea and join the Ti(SO 4 ) 2 In the aqueous solution, stir to dissolve the urea completely, then transfer it to a hydrothermal kettle, and conduct a hydrothermal reaction at 160°C for 20 hours. After the product is washed with deionized water and dried at 110°C, it is roasted at 800°C for 5 hours to obtain TiO 2 Powder photocatalyst. The TiO 2 The crystal form of powder photocatalyst is anatase (see figure 1 ), the average particle size is about 900nm (see Figure 2).

Embodiment 2

[0030] Weigh 3.6g urea and join to 60ml 0.5mol / L of Ti(SO 4 ) 2 In the aqueous solution, stir to dissolve the urea completely, then transfer it to a hydrothermal kettle, and conduct a hydrothermal reaction at 100°C for 10 hours. After the product is washed with ion-free water and dried at 110°C, it is roasted at 400°C for 5 hours to obtain TiO 2 Powder photocatalyst.

Embodiment 3

[0032] Take by weighing 10.8g urea and join the Ti(SO 4 ) 2 In the aqueous solution, stir to completely dissolve the urea, then transfer it to a hydrothermal kettle, and conduct a hydrothermal reaction at 200°C for 40 hours. After the product is washed and dried, it is roasted at 900°C for 5 hours to obtain TiO 2 Powder photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com