Refining method of methyl or ethyl vanillin

A technology of ethyl vanillin and a refining method, which is applied in the field of compound refining, can solve the problems of increasing energy consumption and other costs, the impact of recrystallization yield, and the reduction of product yield, so as to achieve low production cost, low viscosity and high product yield. good color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

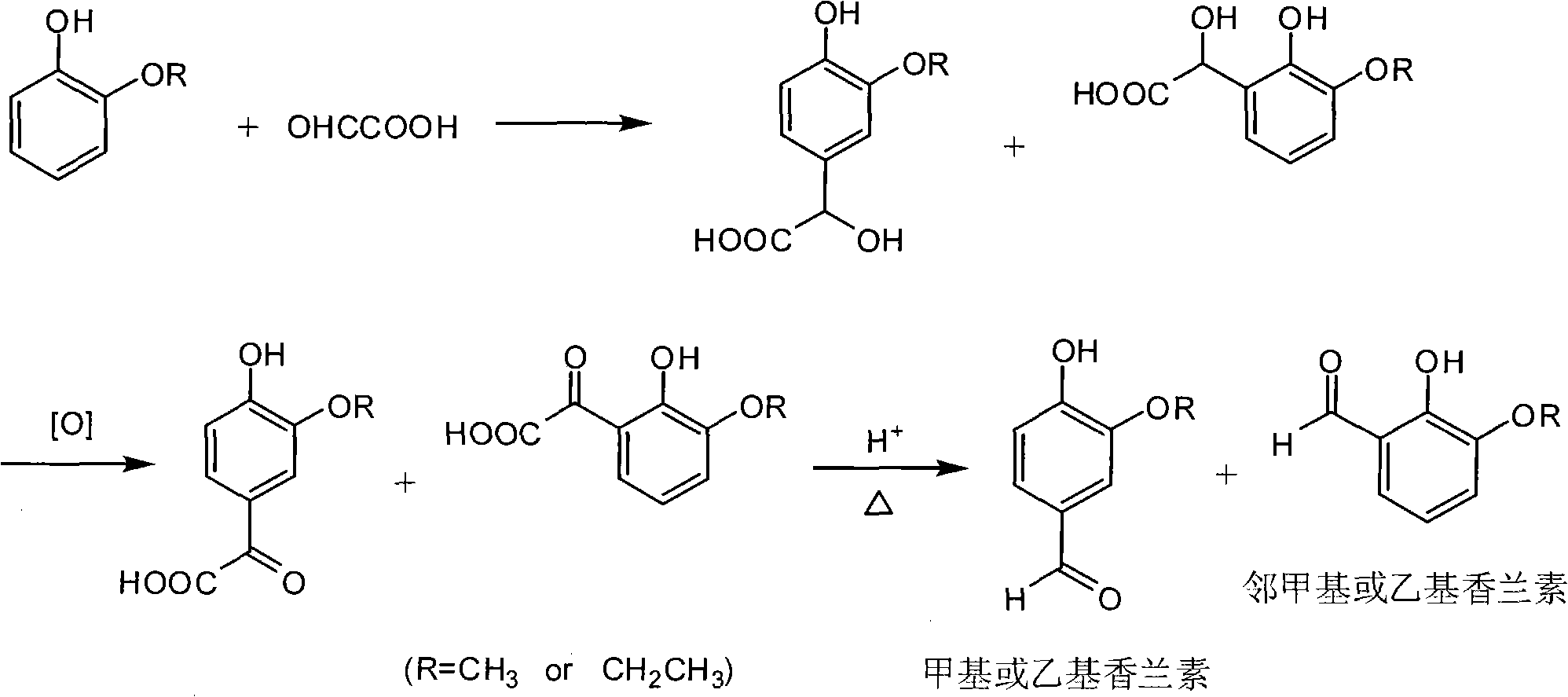

Method used

Image

Examples

Embodiment 1

[0019] Take 10.0 g of crude methyl vanillin (yellow solid, the content of methyl vanillin as measured by HPLC is 95.3%), add 22 mL of petroleum ether with a boiling range of 60 to 90 ° C and 13 mL of toluene, heat to 65 ° C and stir to dissolve The solid was completely dissolved, cooled, and crystallized, filtered to obtain 9.20 g of white crystals (the content of methyl vanillin measured by HPLC method was 99.5%), and the yield was 96% (based on pure product analyzed by HPLC).

Embodiment 2

[0021] Take 10.0 g of crude methyl vanillin (yellow solid, the content of methyl vanillin as measured by HPLC is 95.3%), add 22 mL of n-heptane and 13 mL of toluene, heat to 65 °C and stir to completely dissolve the solid, cool and precipitate Crystallized and filtered to obtain 9.18 g of white crystals (the content of methyl vanillin measured by HPLC method was 99.3%), and the yield was 95.6% (based on the pure product analyzed by HPLC).

Embodiment 3

[0023] Take 10.0 g of crude methyl vanillin (yellow solid, the content of methyl vanillin as measured by HPLC is 95.3%), add 10 mL of n-hexane, 12 mL of n-heptane and 13 mL of toluene, heat to 65°C and stir to dissolve the solid completely , cooling, crystallization, and filtration to obtain 9.20 g of white crystals (the content of methyl vanillin measured by HPLC method is 99.3%), and the yield is 95.8% (based on pure product analyzed by HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com