Submerged guide roller of copper foil post-processor

A technology of machine fluid and guide roller, which is applied in the direction of household components, etc., can solve the problems of insufficient resistance to strong acid and strong alkali, easy formation of copper lumps, single performance, etc., and achieve the effect of performance improvement, reduction of unevenness, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below through specific examples.

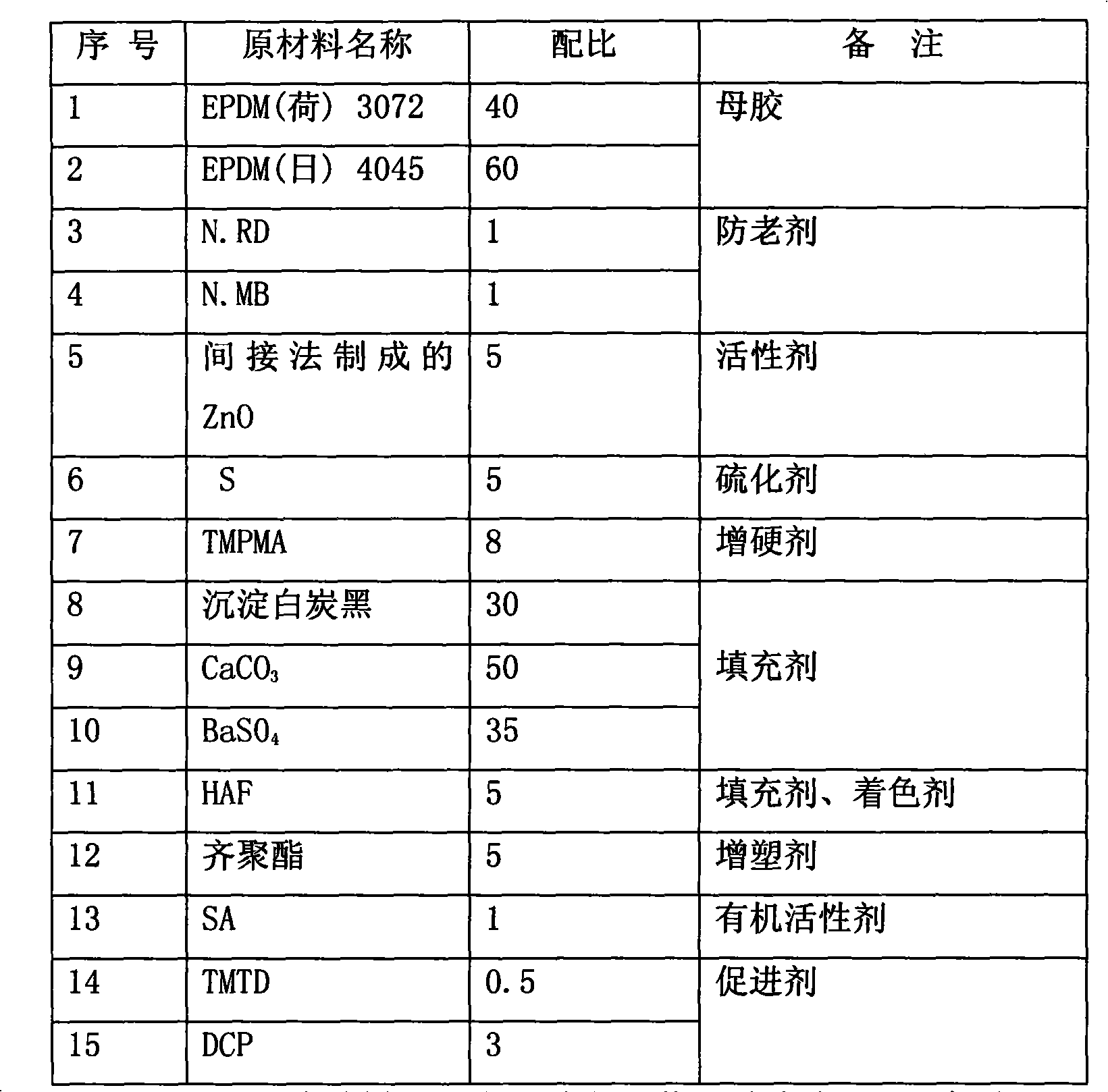

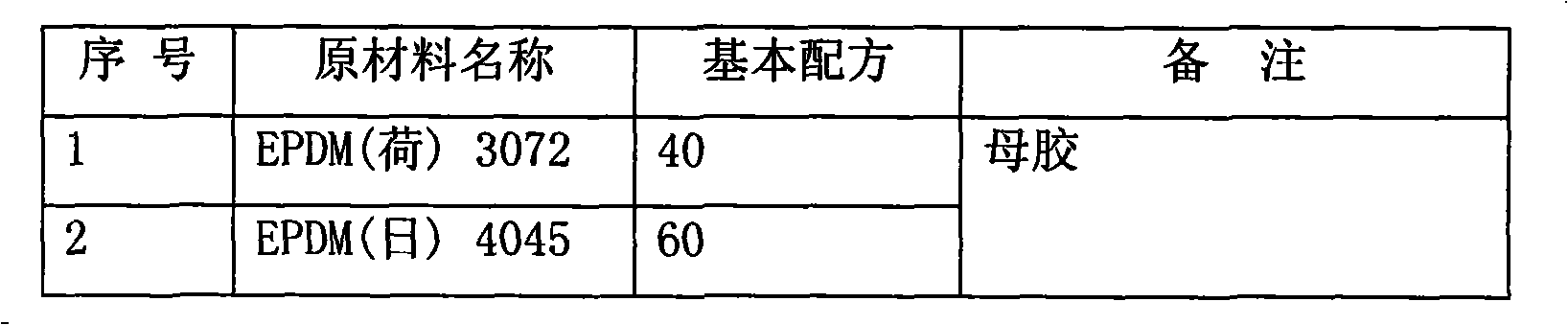

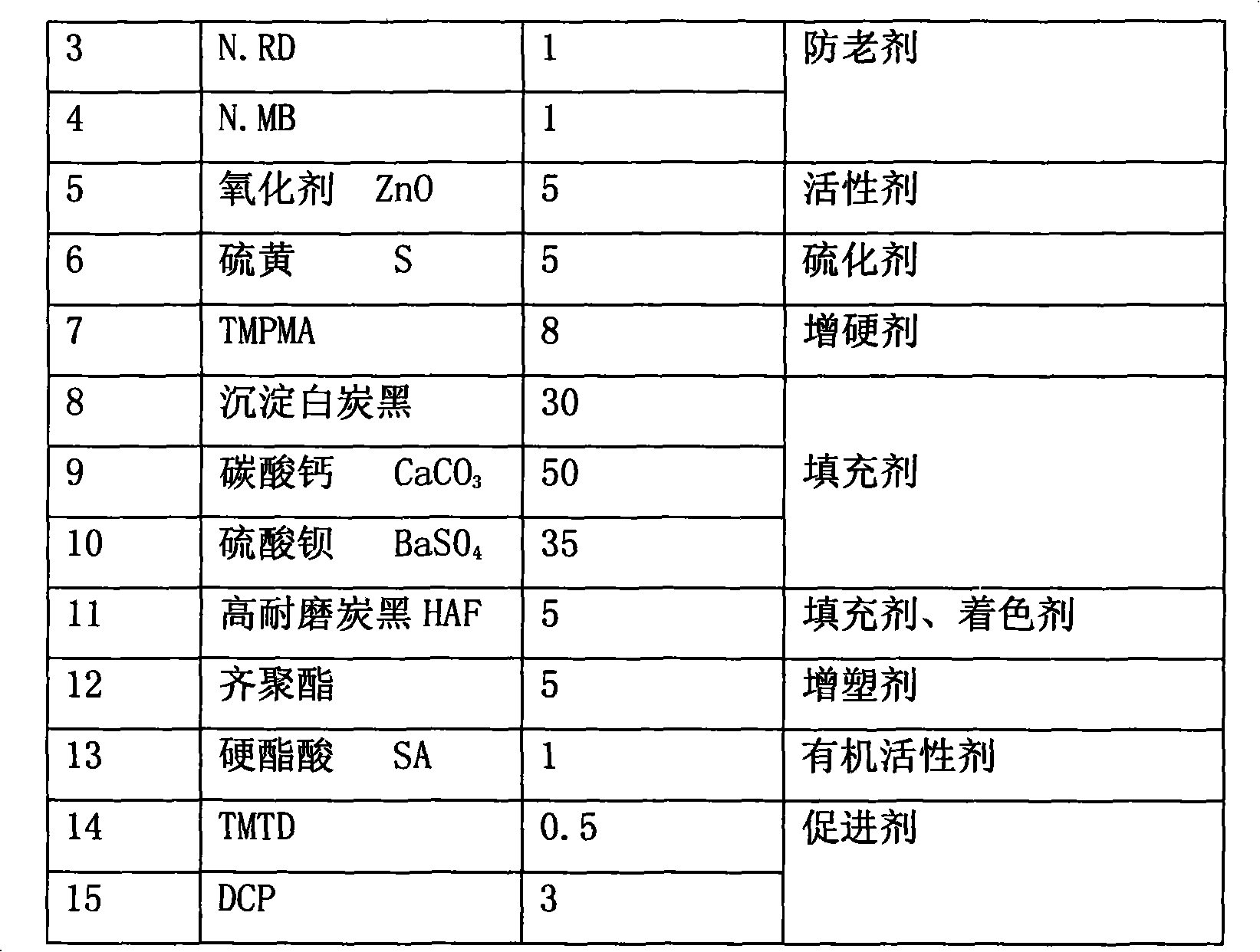

[0022] A copper foil post-processing machine liquid guide roller, which is compounded by the following raw materials in parts by weight;

[0023]

[0024]

[0025] Prepared by the following process, the process comprises the following steps in turn:

[0026] (1) Material preparation: check the raw materials, check whether the manufacturer, batch number, and material list are qualified, weigh the weight according to the formula requirements, and subcontract the label;

[0027] (2) Mixing and inspection by conventional methods: including plasticizing small materials, book-passing, throwing large materials, book-passing, making triangular bags and making small test pieces in sequence, and finally inspecting hardness, tensile strength, tear strength, permanent Deformation, abrasion, insulation performance, etc.;

[0028] (3) Filtration: After all the indicators have passed the inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com