Manufacture method of high grade high density bamboo fiber woolen blanket

A manufacturing method, the technology of high-density bamboo, is applied in the manufacture of blankets and the manufacture of high-count and high-density bamboo fiber blankets to achieve the effects of enhancing grades, improving wrinkle resistance, and strong hand feeling and plush feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

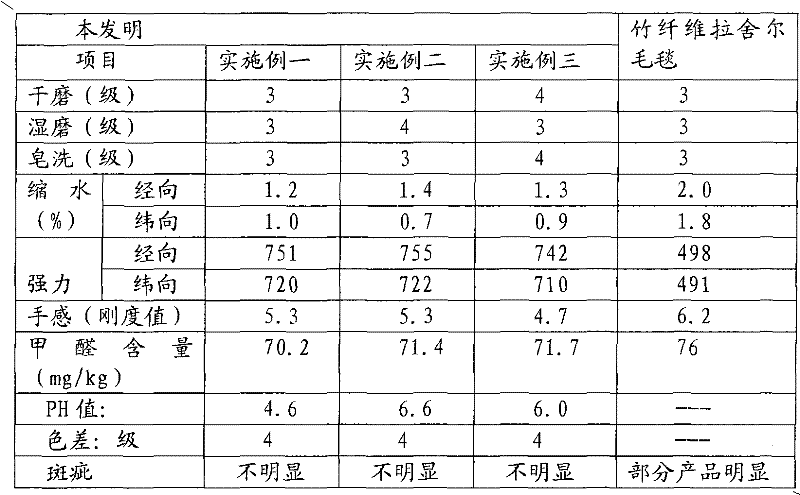

Embodiment 1

[0021] A kind of manufacture method of high count and high density bamboo fiber blanket, at first select the bamboo fiber yarn of 12S to make gray cloth, in the padding liquid of gray cloth, the solid content of NaOH is 38g / L in the padding liquid, H The solid content of O2 is 15g / L, the content of stabilizer GJ101 is 8g / L, the content of scouring agent 22ECO is 8g / L, and the excess rate is 105%. After bleaching, it is steamed at 100 degrees Celsius; The steps of washing the bristles of the high-speed brushing machine. After washing, the gray cloth is printed, and the printing is specifically: using Marcocion & reg; P-type dyes for the printing process, using printing drying, steaming (baking), washing, soaping, and washing, Marcocion & reg; P-type dyes It contains 5% urea, 2.5% baking soda, 1% anti-staining salt and 40% sodium alginate. After printing, it is pre-dried at about 100°C, and then steamed in water vapor at 103°C. 3 minutes: after baking for 2 minutes at a tempera...

Embodiment 2

[0023] A kind of manufacture method of high count and high density bamboo fiber blanket, at first select the bamboo fiber yarn of 12S to make gray cloth, in the padding liquid of gray cloth, the solid content of NaOH is 38g / L in the padding liquid, H The solid content of O2 is 15g / L, the content of stabilizer GJ101 is 8g / L, the content of scouring agent 22ECO is 8g / L, and the excess rate is 108%. After bleaching, it is steamed at 100 degrees Celsius; The steps of washing the bristles of the high-speed brushing machine. After washing, the gray cloth is printed, and the printing is specifically: using Marcocion & reg; P-type dyes for the printing process, using printing drying, steaming (baking), washing, soaping, and washing, Marcocion & reg; P-type dyes It contains 5% urea, 2.5% baking soda, 1% anti-staining salt and 40% sodium alginate. After printing, it is pre-dried at about 100°C, and then steamed in water vapor at 103°C. 3 minutes: after baking for 1 minute at a temperat...

Embodiment 3

[0025] A kind of manufacture method of high count and high density bamboo fiber blanket, at first select the bamboo fiber yarn of 12S to make gray cloth, in the padding liquid of gray cloth, the solid content of NaOH in the padding liquid is 38g / L, H 2 o 2 The solid content is 15g / L, the content of stabilizer GJ101 is 8g / L, the content of scouring agent 22ECO is 8g / L, and the excess rate is 106%. After bleaching, it is steamed at 100 degrees Celsius; then steamed The final gray cloth is washed by the bristles of a high-speed brushing machine. After washing, the gray cloth is printed, and the printing is specifically: using Marcocion & reg; P-type dyes for the printing process, using printing drying, steaming (baking), washing, soaping, and washing, Marcocion & reg; P-type dyes It contains 5% urea, 2.5% baking soda, 1% anti-staining salt and 40% sodium alginate. After printing, it is pre-dried at about 100°C, and then steamed in water vapor at 103°C. 3 minutes: after baking f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com