High compressed air cylinder filling machine

A high-compression and compression cylinder technology, applied in liquid variable volume machinery, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as easy use that is not suitable for general consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principle and structure of the present invention are now further described in detail as implementation examples in conjunction with the accompanying drawings; however, the implementation examples are only for providing illustration and explanation, and should not be used to limit the practical extension scope of the present invention and its invention claims scope of protection.

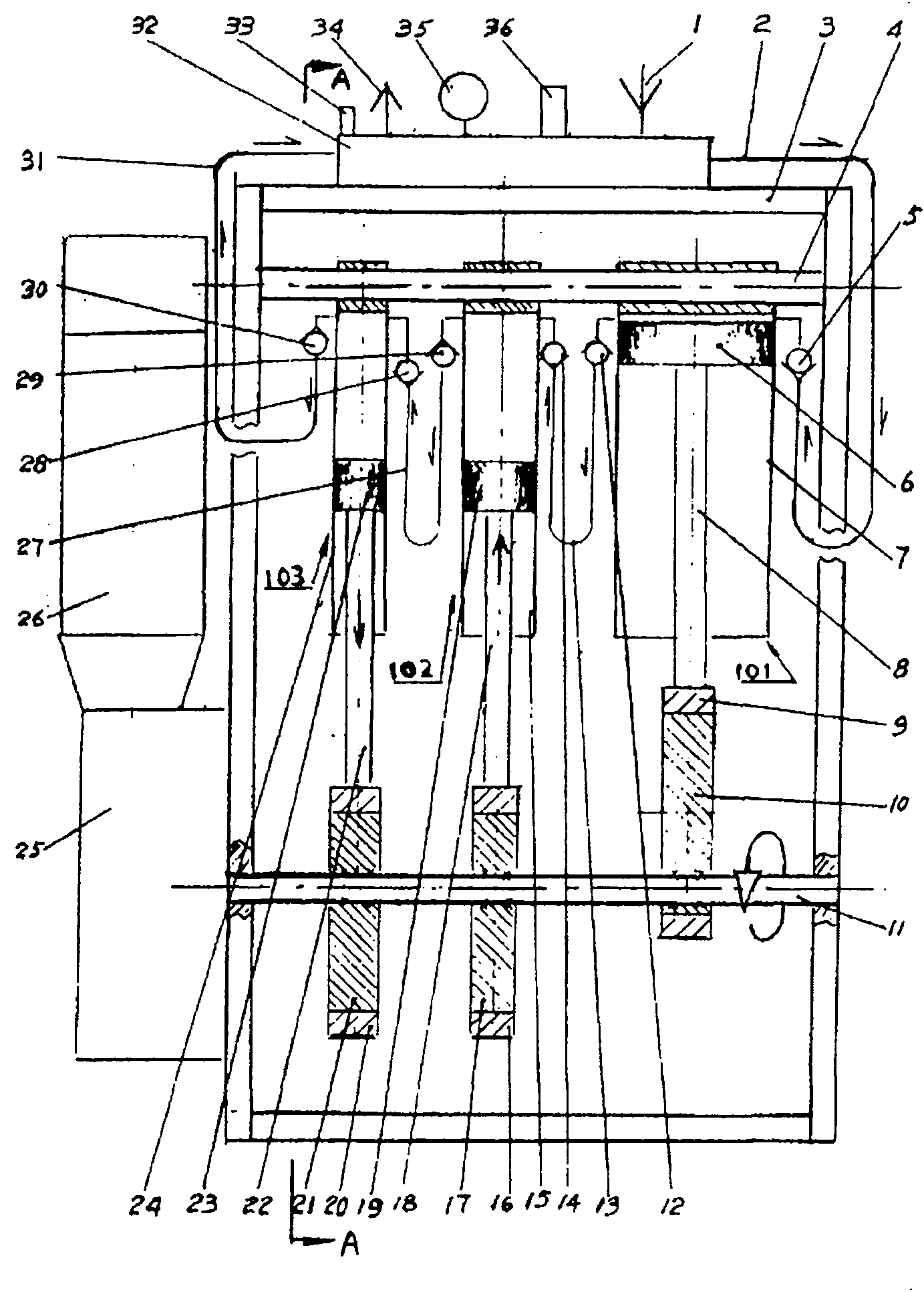

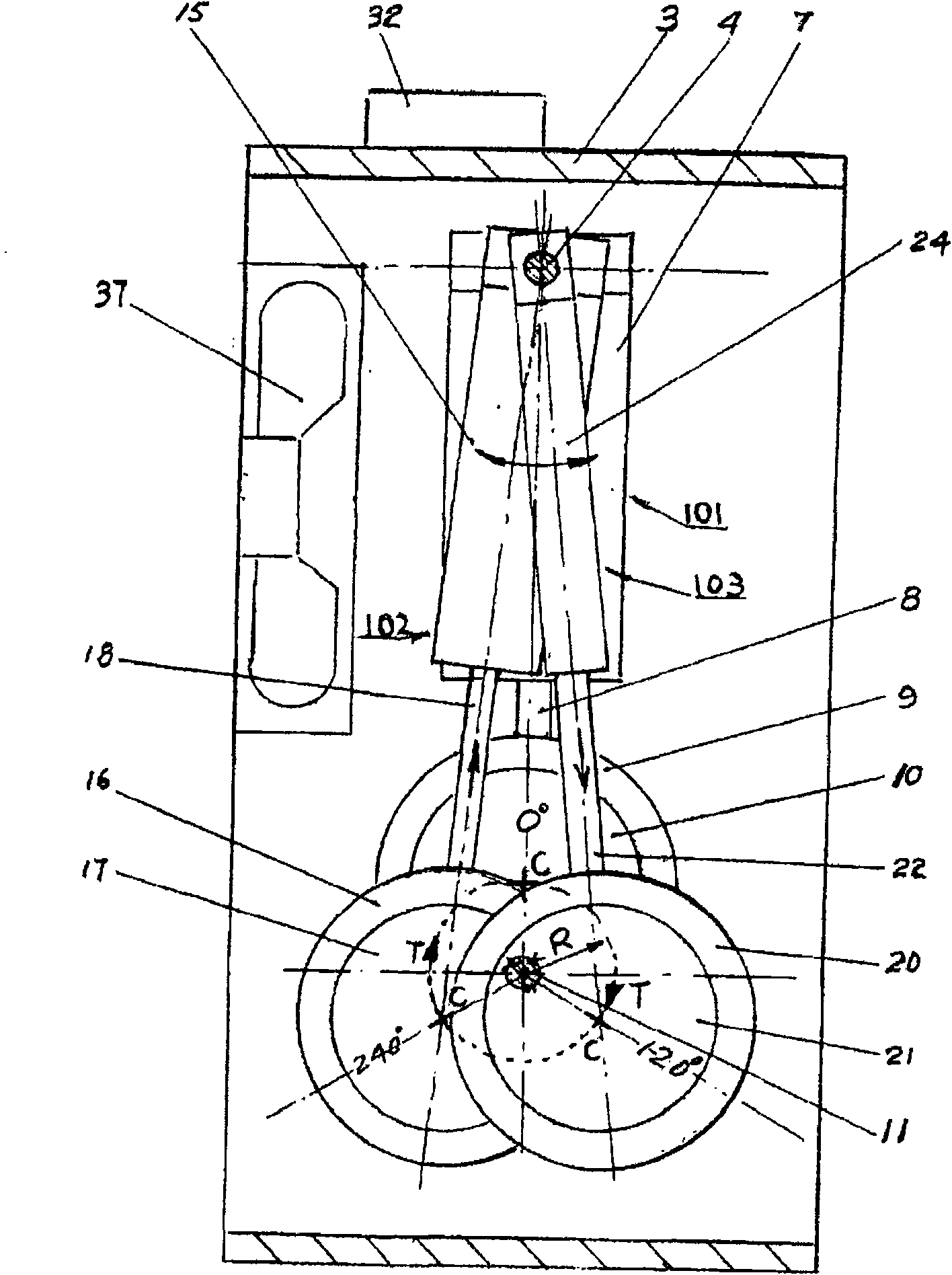

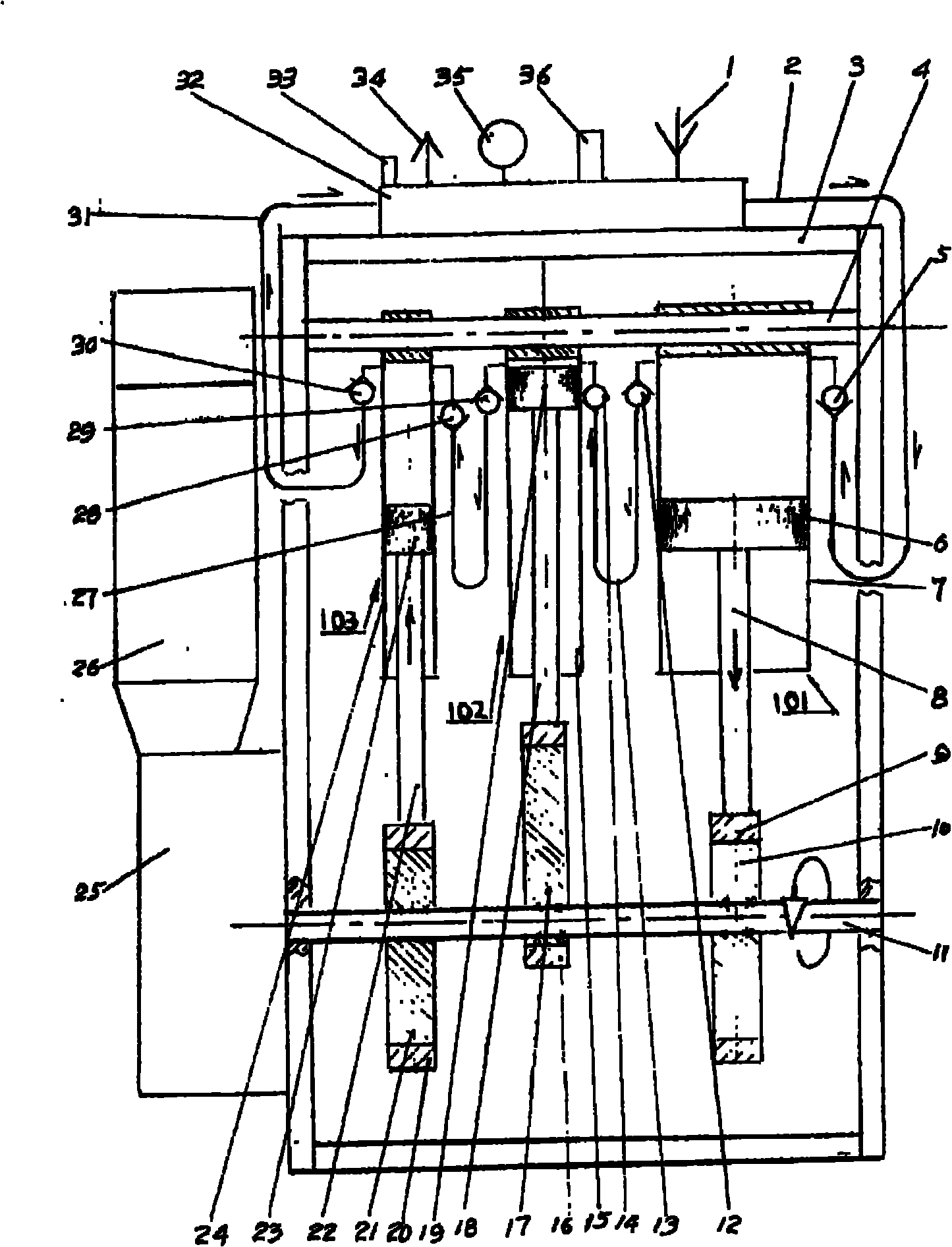

[0022] Such as Figure 1 to Figure 4 Demonstration: According to the preferred implementation example of the high-compression gas bottle filling machine 100 of the present invention, the operating organization of the present invention mainly includes an eccentric drive mechanism and a group of pendulum compression cylinder mechanisms; Box 25, drive shaft 11, and three eccentric drive wheels 10, 17, 21 are formed, and according to the preferred implementation example of the present invention, described one group of pendulum type compression cylinder mechanism is to select three pendulum typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com