Touch type liquid crystal display, touch method, array substrate and manufacture method thereof

A technology for liquid crystal displays and array substrates, applied in the fields of touch-type liquid crystal displays, array substrates and their manufacture, and touch methods, capable of solving the problems of increasing liquid crystal panels, floating images, increasing manufacturing processes and production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

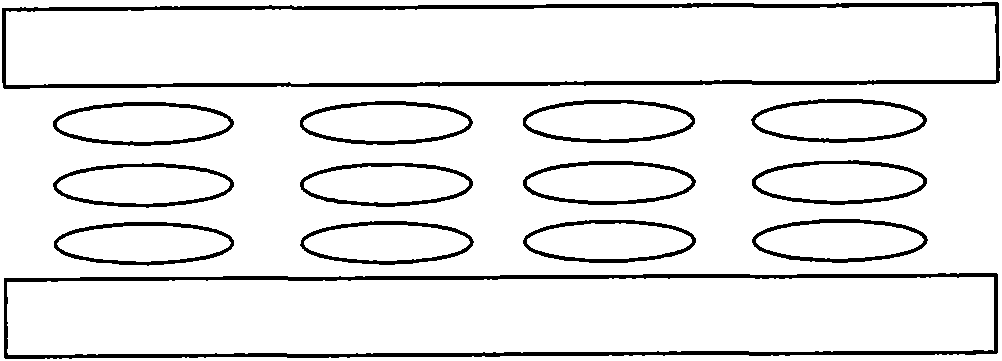

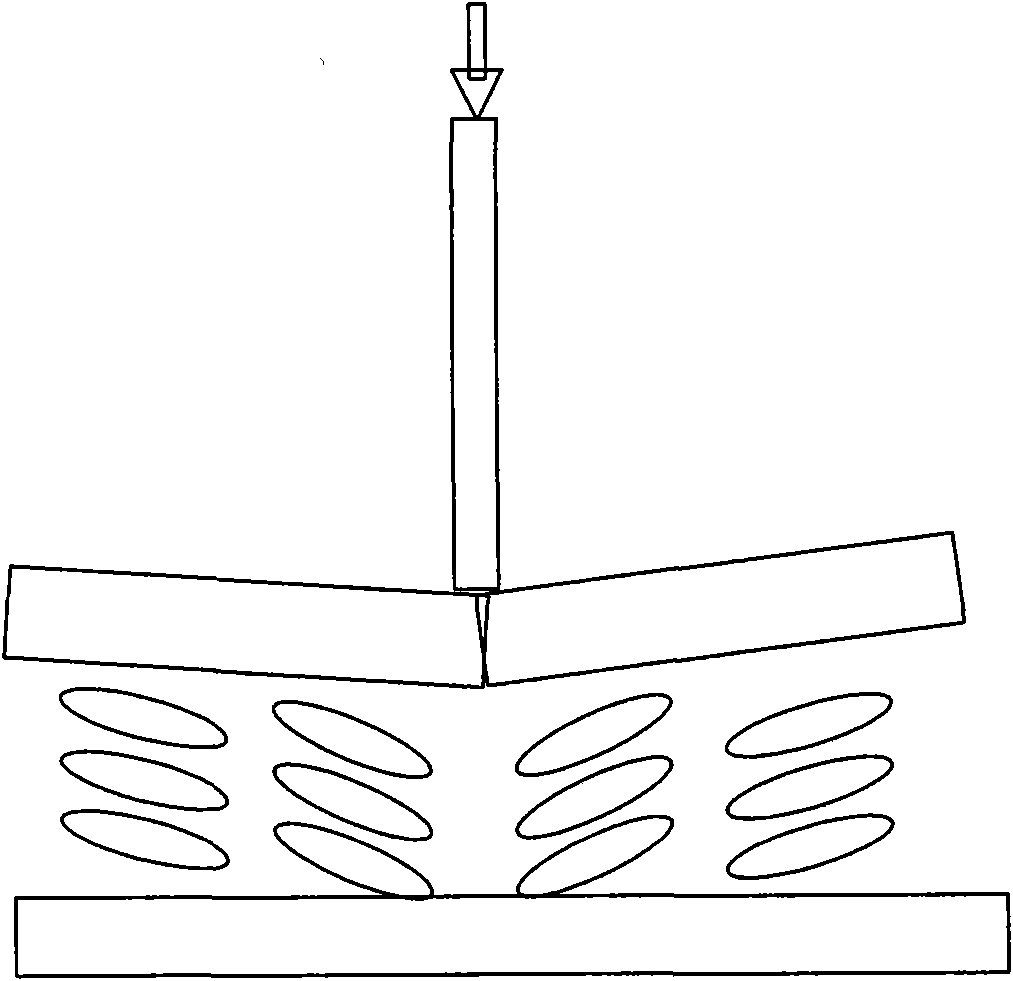

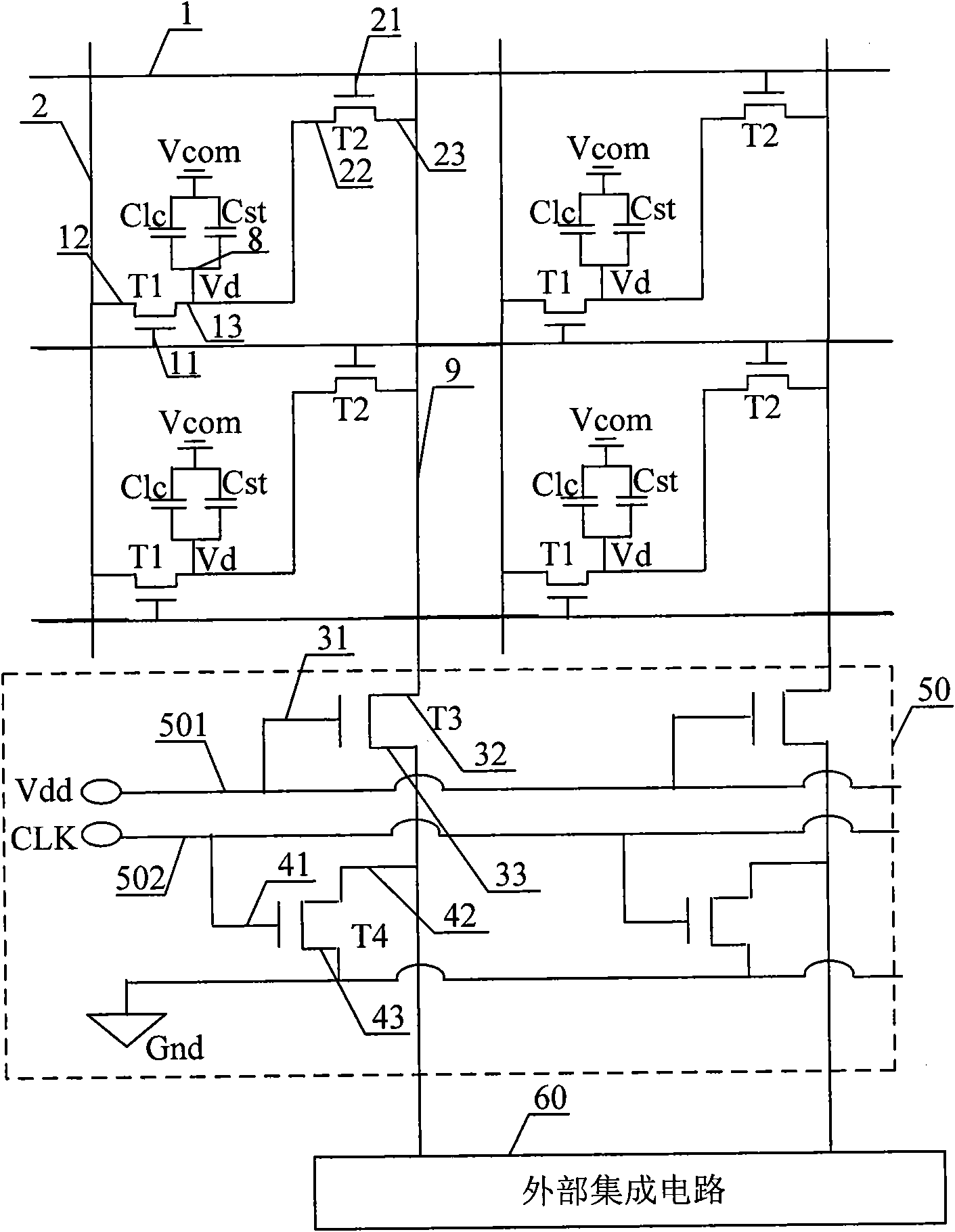

[0068] figure 1 Shown is a schematic diagram of liquid crystal arrangement when the liquid crystal panel of the present invention is not touched, figure 2 Shown is a schematic diagram of liquid crystal arrangement when the liquid crystal panel of the present invention is touched, as figure 1 and figure 2 As shown, the liquid crystal material is filled between the pixel electrode and the common electrode. When the liquid crystal panel is touched, the gap between the liquid crystal cells will change, and then the orientation of the liquid crystal will change. Because the liquid crystal has anisotropic characteristics, that is, its vertical dielectric The electrical constant and the horizontal dielectric constant are different from each other, so the change of the orientation of the liquid crystal will cause the chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com