OLED (Organic Light Emitting Diode) lighting substrate, OLED lighting device and manufacturing methods thereof

A technology for lighting devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as cathode-anode short-circuit light emission, high current intensity, and electrode burnout, so as to reduce the concentration of current intensity, Increase resistance, reduce the effect of easy short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

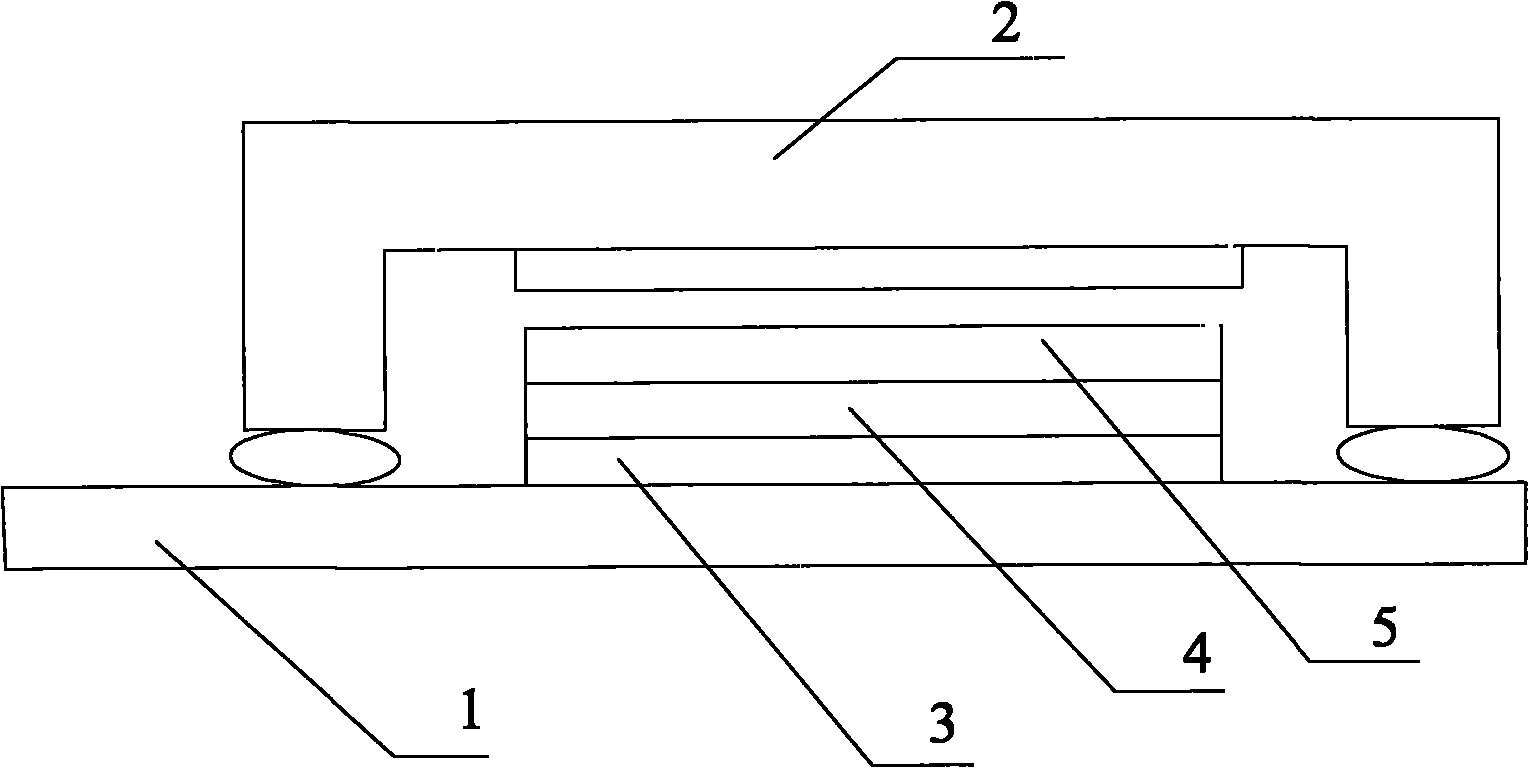

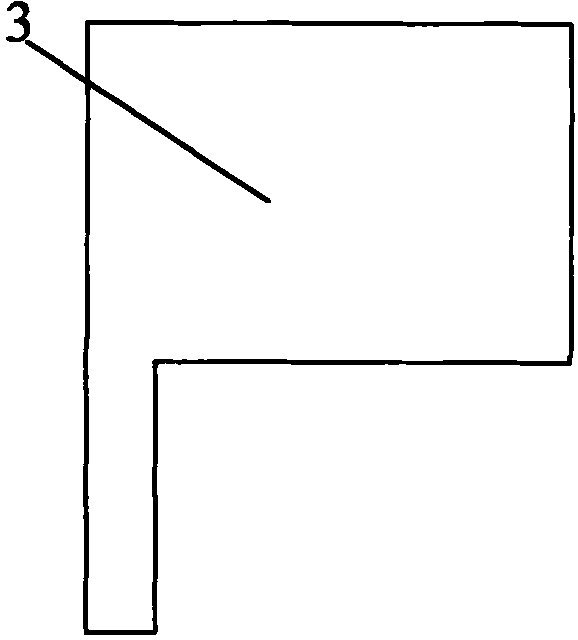

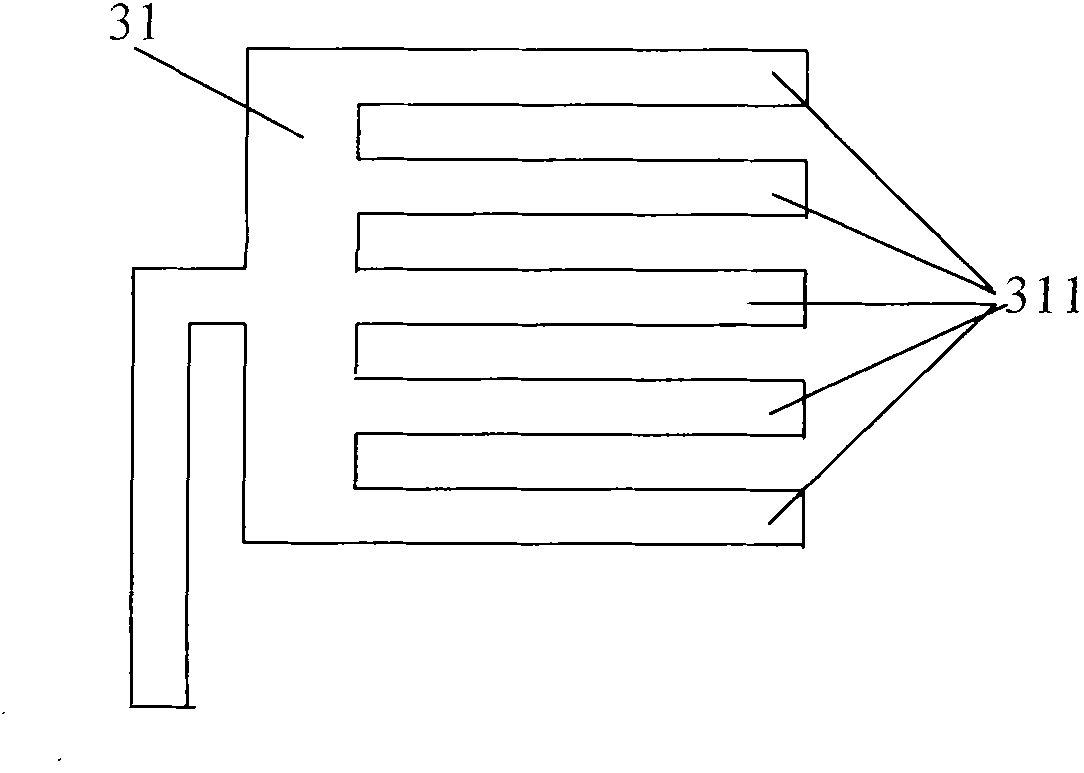

[0052] The substrate includes an anode, an organic functional layer and a cathode arranged in layers, and the anode is a transparent anode, wherein the anode is split into at least two branch anodes. Such as image 3 As shown, it is a schematic diagram of the structure of the substrate anode in this embodiment. The anode 31 includes five branch anodes 311 arranged in parallel. The overall design of the anode in the prior art, in this embodiment, the branch current on each branch anode 311 is about 1 / 5 of the original current, even if a current aggregation effect occurs on a branch anode 311, the accumulated current intensity is greatly weakened .

[0053] By subdividing the anode 31 of the substrate into a plurality of branch anodes, the resistance on each branch anode is increased, so that the branch anodes play a role of shunting, and even if current aggregation occurs on the branch anodes, the concentration of the generated current intensity will be greatly weakened, there...

Embodiment 2

[0056] The substrate includes a stacked anode, an organic functional layer and a cathode, and the anode is a transparent anode. In this embodiment, the substrate anode 41 includes three branch anodes 411 arranged in parallel, such as Figure 4a As shown, it is a schematic cross-sectional view of the substrate anode in this embodiment, and the anode 41 is formed in a comb shape as a whole.

[0057] Since the resistance of each branch anode 411 is relatively large, it will increase loss and generate heat easily. In this embodiment, in order to adjust the resistance of the branch anode 411, in this embodiment, in the direction of each branch anode 411, the organic function The surface of the layer is also covered with an auxiliary electrode layer 412, which is used to reduce the resistance on the branch anode 411. Since the auxiliary electrode layer 412 is opaque, in order not to affect the light-emitting area too much, the line width of the auxiliary electrode layer 412 is small...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com