Composite flue gas desulfurization agent and preparation method thereof

A desulfurizer and composite technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of difficult preparation process and complicated preparation method, achieve low cost, less consumption, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

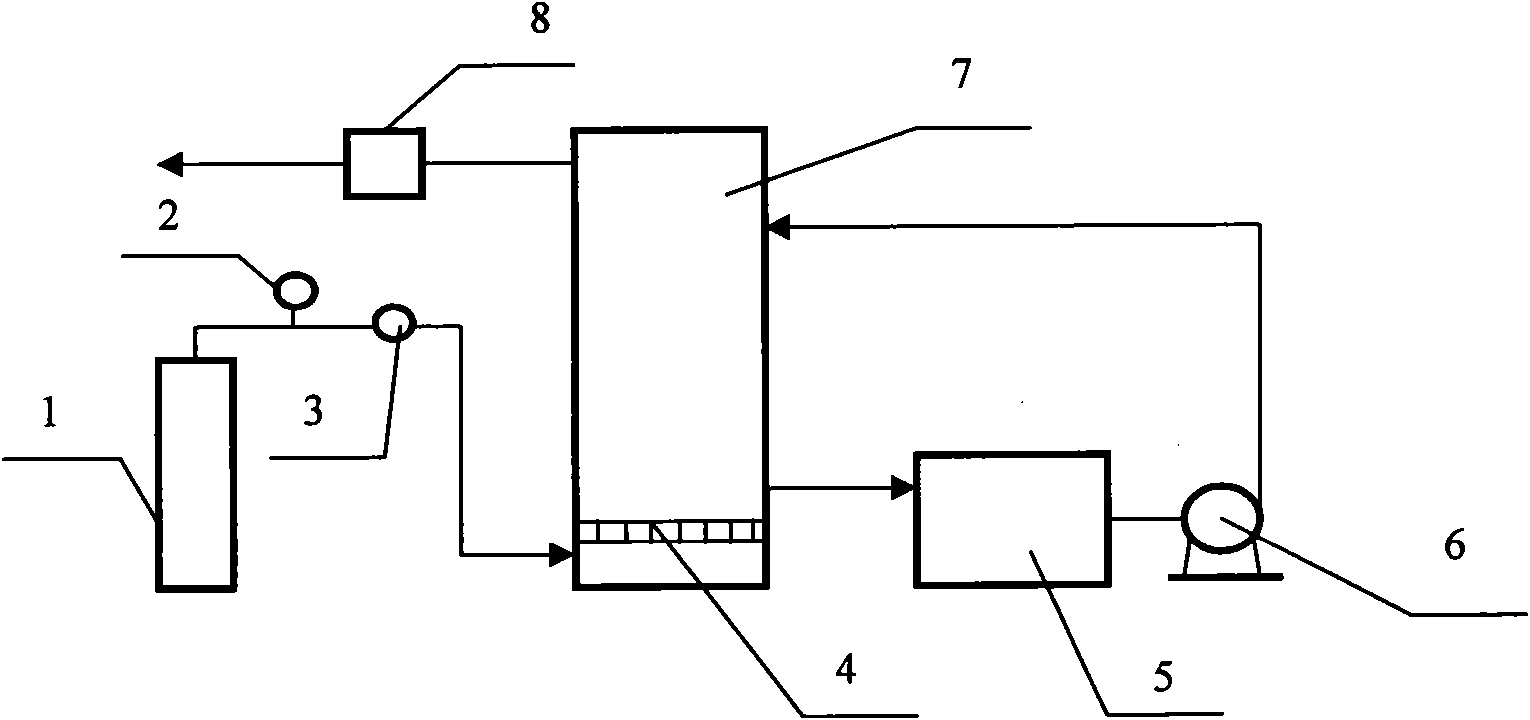

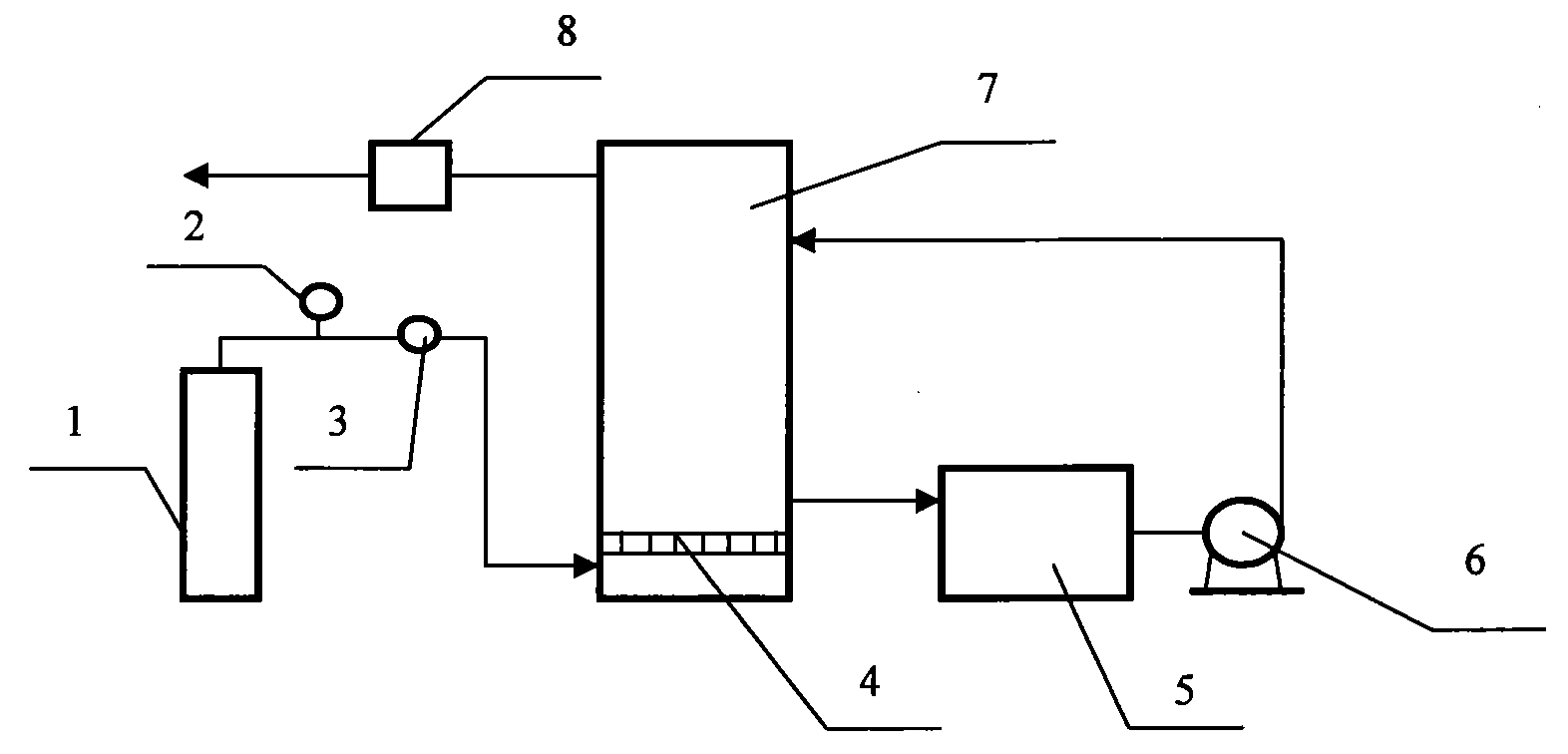

[0022] Such as figure 1 shown. Account for the mass percent composition of solvent by methyldiethanolamine (MDEA) be 1.0~12.0%, the concentration of surfactant 2-octyl dodecyl sodium sulfate (GC20S) is 3.4 * 10 -6 ~30×10 -6 mol / L to configure desulfurization solution. Contains SO 2 The flue gas of 5wt% passes through the flow meter 3 to measure the flow rate, and the flow rate is set to 2m 3 / h, 4m 3 / h, 6m 3 / h, 8m 3 / h. After the gas is metered, it enters the desulfurization tower 7, which has a diameter of 100mm and a height of 1500mm. The gas distributor 4 installed at the bottom of the desulfurization tower can form the gas into bubbles. The desulfurization liquid tank 5 is equipped with an electric heater, which can change the temperature of the liquid. In this embodiment, the set temperature is 25°C. Circulating through the pump 6, the SO in the flue gas 2 It is absorbed by the desulfurization liquid in the desulfurization tower 7. The purified flue gas flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com