Method for determining oil content of vegetable oil material based on ultrasonic assistant extraction

An ultrasonic wave and oil content technology, which is applied in the field of determination of oil content of vegetable oils, can solve the problems of limited popularization and application, high risk of experimentation, high price, etc., and achieve the effect of broad application prospects, simple instrument requirements, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

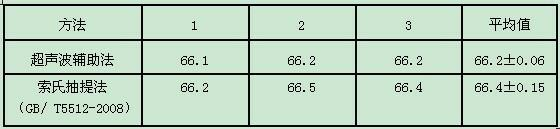

[0034] Embodiment 1: Determination of oil content of yellow mustard

[0035] (1) Yellow mustard seeds were collected from Yulin, Shaanxi, air-dried naturally, removed impurities, and evenly sampled.

[0036] (2) Yellow mustard seed sample preparation: weigh 5.0g-10.0g sample (m 1 ), the sample is accurate to 0.001g, put it in an oven at 105°C and dry for 30 minutes, pour it into a mortar while it is hot, add about 4g of degreased fine sand, and grind together, grind the sample and fine sand until oily, Transfer without damage to a corked Erlenmeyer flask.

[0037] (3) Ultrasonic assisted leaching: Add petroleum ether according to the sample-to-petroleum ether solid-liquid ratio (sample weight to petroleum ether volume ratio) of 1:12 (w / v). Place the triangular flask in an ultrasonic instrument, set the ultrasonic frequency to 45KHz, and the ultrasonic power to 90W, extract for 15 minutes, and collect the extract by suction filtration; repeat the extraction 4 times in this wa...

Embodiment 2

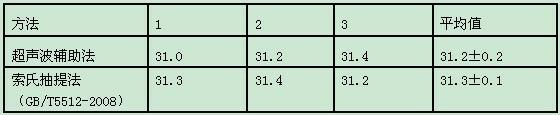

[0045] Embodiment 2: Camellia oleifera seed oil content determination

[0046] (1) Camellia oleifera seeds are collected from Youxi, Fujian, air-dried naturally, removed impurities, shelled, and evenly harvested camellia oleifera seeds.

[0047] (2) Preparation of Camellia oleifera seed samples: Weigh 5.0g-10.0g samples (m 1 ), sample (m 1 ) to an accuracy of 0.001g, put it in an oven at 105°C for 30 minutes, pour it into a mortar while it is still hot, add about 4g of degreased fine sand, and grind together. In a corked Erlenmeyer flask.

[0048] (3) Ultrasonic assisted leaching: add petroleum ether according to the sample to petroleum ether solid-liquid ratio (weight to volume ratio) of 1:13 (w / v). Put the stoppered Erlenmeyer flask in an ultrasonic cleaner, set the ultrasonic frequency to 45KHz and the ultrasonic power to 90W to extract for 12 minutes, and collect the extract by centrifugation; repeat the extraction for 5 times, and combine the extract .

[0049] (4) T...

Embodiment 3

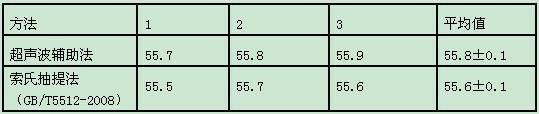

[0057] Embodiment 3: determination of walnut kernel oil content

[0058] (1) Walnuts are collected from Huanglong, Shaanxi, air-dried naturally, removed impurities, shelled, and evenly harvested walnut kernels.

[0059] (2) Walnut kernel sample preparation: Slice the walnut kernel and weigh 5.0g-10.0g sample (m 1 ), sample (m 1 ) to an accuracy of 0.001g, put it in an oven at 105°C for 30 minutes, pour it into a mortar while it is still hot, add about 4g of degreased fine sand, and grind together. In a corked Erlenmeyer flask.

[0060] (3) Ultrasonic-assisted leaching: Add petroleum ether according to the sample-to-petroleum ether solid-liquid ratio (weight to volume ratio) of 1:14 (w / v). Place the corked triangular flask in an ultrasonic cleaner, set the ultrasonic frequency to 45KHz, and the ultrasonic power to 100W for 10 minutes of leaching, and collect the leaching solution by suction; repeat the extraction 6 times in this way, and combine the leaching liquid.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com