Parallel photoetching write-through system

A lithography direct writing and optical system technology, applied in the field of micro-nano processing devices, can solve the problems affecting the quality of lithography workpieces, defocusing, etc., and achieve high resolution and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

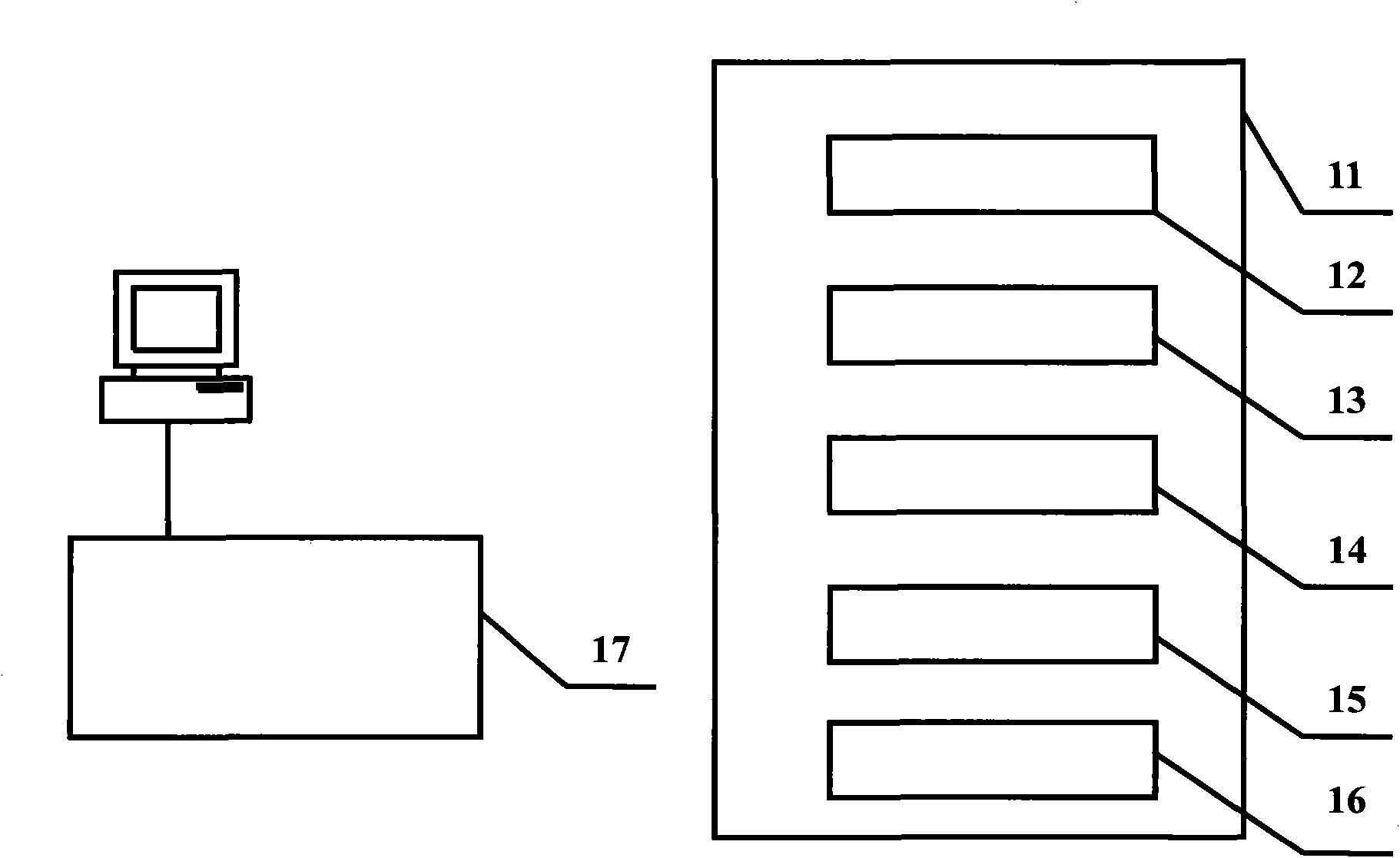

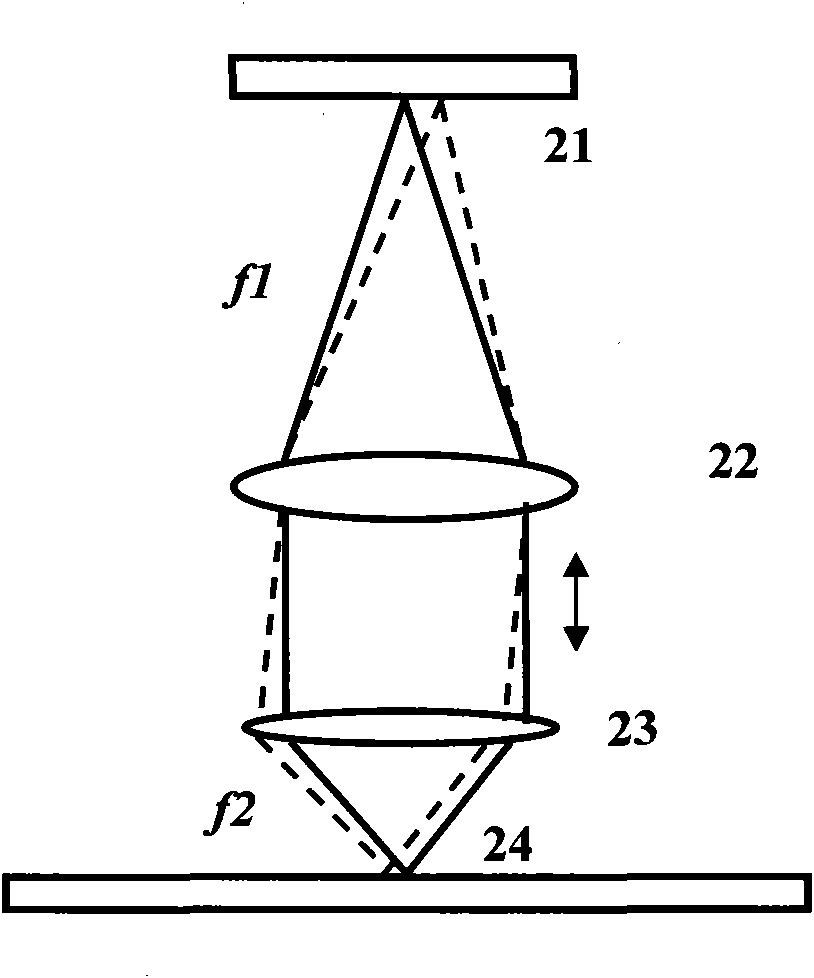

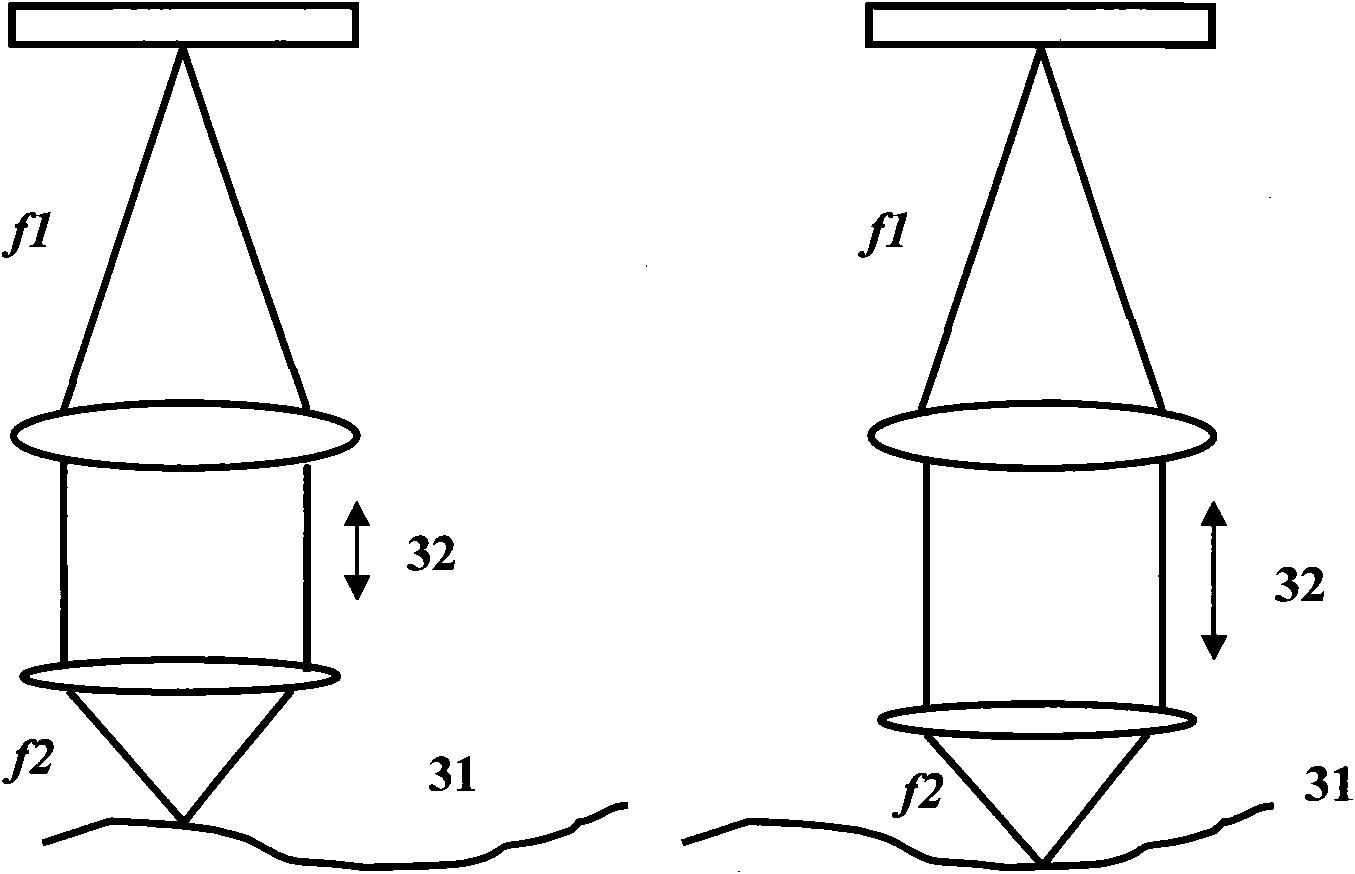

[0032] A multi-axis parallel lithography direct writing system, see Figure 4 As shown, the mechanical frame 41 includes a light source, an optical system, a spatial light modulator, a motion system, and a sensor, and a control computer 417 and a control drive unit 418 are located outside the mechanical frame. The specific description is as follows:

[0033] a) The light emitted by the light source 42 illuminates the spatial light modulator 43 after beam expansion and collimation, the light modulated by the spatial light modulator passes through the partial reflector 44, enters the tube lens (Tube lens) 45, and passes through the partial reflection After the mirror 46 passes through the objective lens 47, the image is placed on the work surface of the workpiece table located on the multi-axis platform 48, and the light reflected from the workpiece surface enters the optical system again, passes through 47, 46, 45, 44, and lens group 49 successively, and enters the CCD sensor 4...

Embodiment 2

[0044] like Figure 5 As shown, the number of motion axes of the motion platform 58 is increased or decreased, and other configurations are the same as in Embodiment 1.

[0045] Reduce the number of motion axes. For example, the X, Y plane direct writing system can be composed of X, Y motion platforms and small-stroke servo moving parts. Similarly, the X, R plane polar coordinate direct writing system can be formed. X, Y, Z systems wait.

[0046] Increasing the number of motion axes brings more degrees of freedom, enabling the direct writing system to achieve more operating modes. For example, adding an axis that makes the table move in pitch, so that the light is always perpendicular to the workpiece when processing curved surfaces, which improves the processing accuracy.

Embodiment 3

[0048] like Figure 6 As shown, the gantry structure system. The configuration of the optical components remains unchanged. The light source, spatial light modulator, optical system, CCD and Z-axis are taken as a whole. The platform is used to place photolithographic workpieces to form a X, Y, Z gantry three-axis parallel photolithography system. This structure is suitable for designing models with a large photolithography format (greater than 500mm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com