Comprehensive treatment device for rubbishes

A comprehensive treatment and equipment technology, applied in the direction of solid separation, chemical instruments and methods, solid waste removal, etc., to achieve the effect of large processing capacity, ecological environment protection, and large market space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

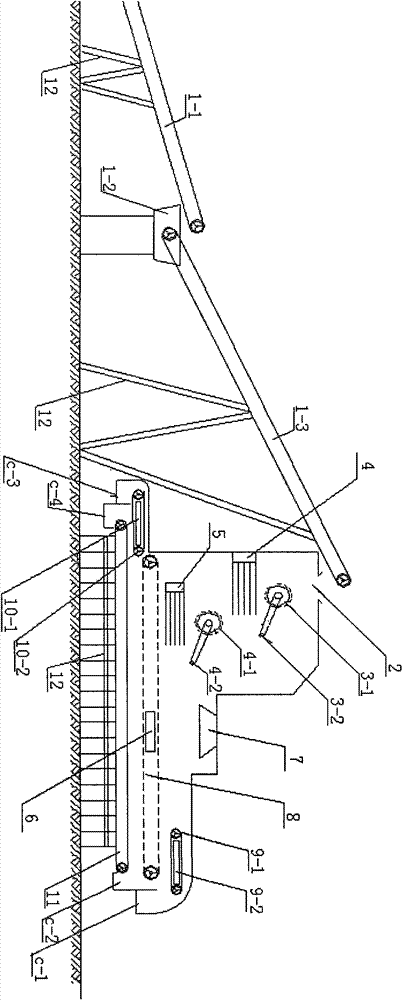

[0023] As shown in the figure, the garbage conveyor belt has two layers 1-1, 1-3, and is transferred through the hopper 1-2. There is a feed port 2 on the top of the casing, and a sorter is set under the feed port. The sorter is driven by a motor. 3-2. The gear 3-1 with arc-shaped teeth on the surface is composed of a belt or chain connected to the motor and the gear; a comb-shaped device 4 for crushing garbage is installed under the sorter, and a comb-shaped device 4 is installed under the comb-shaped device 4. Chain sieve 8; a blower 6 is arranged on one side of the middle section of the chain sieve 8, and the air outlet of the blower 6 is arranged upwardly in the middle of the two chains of the chain sieve; 8 A garbage magnetic separator is set at the other end; a belt conveyor is set below the chain screen; a garbage magnetic separator is set above one end of the belt conveyor, and the garbage magnetic separator is conveyed by belt conveyor 9-1 and installed on the belt Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com