Ultrasonic external field continuous casting and rolling machine

A cast-rolling and outfield technology, applied in metal rolling, casting equipment, manufacturing tools, etc., can solve the problems of high cost of refiner, easy precipitation, production of can slabs and automobile plates, etc., to improve the structure and mechanical properties , Widely promote the application value and improve the effect of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

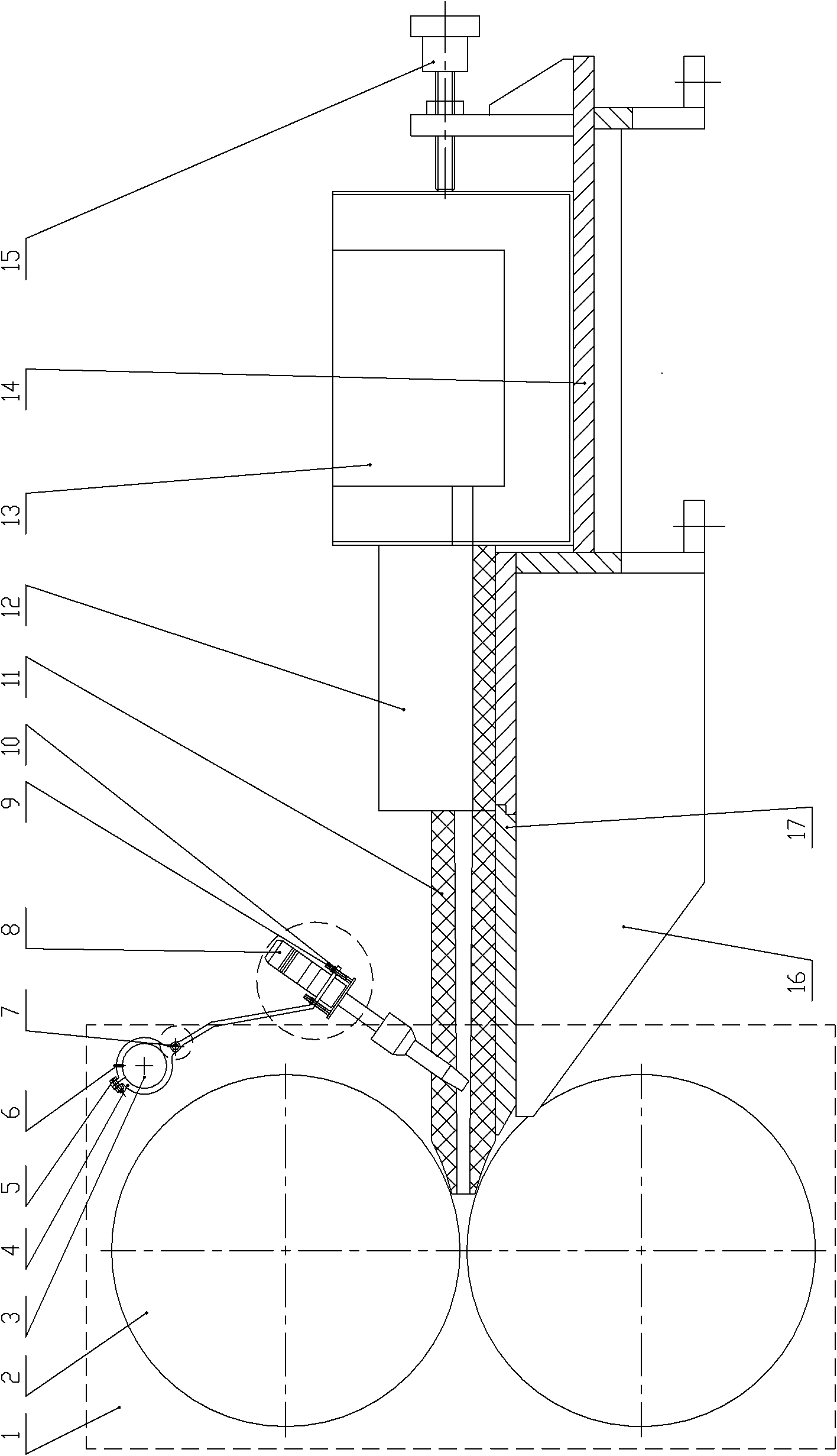

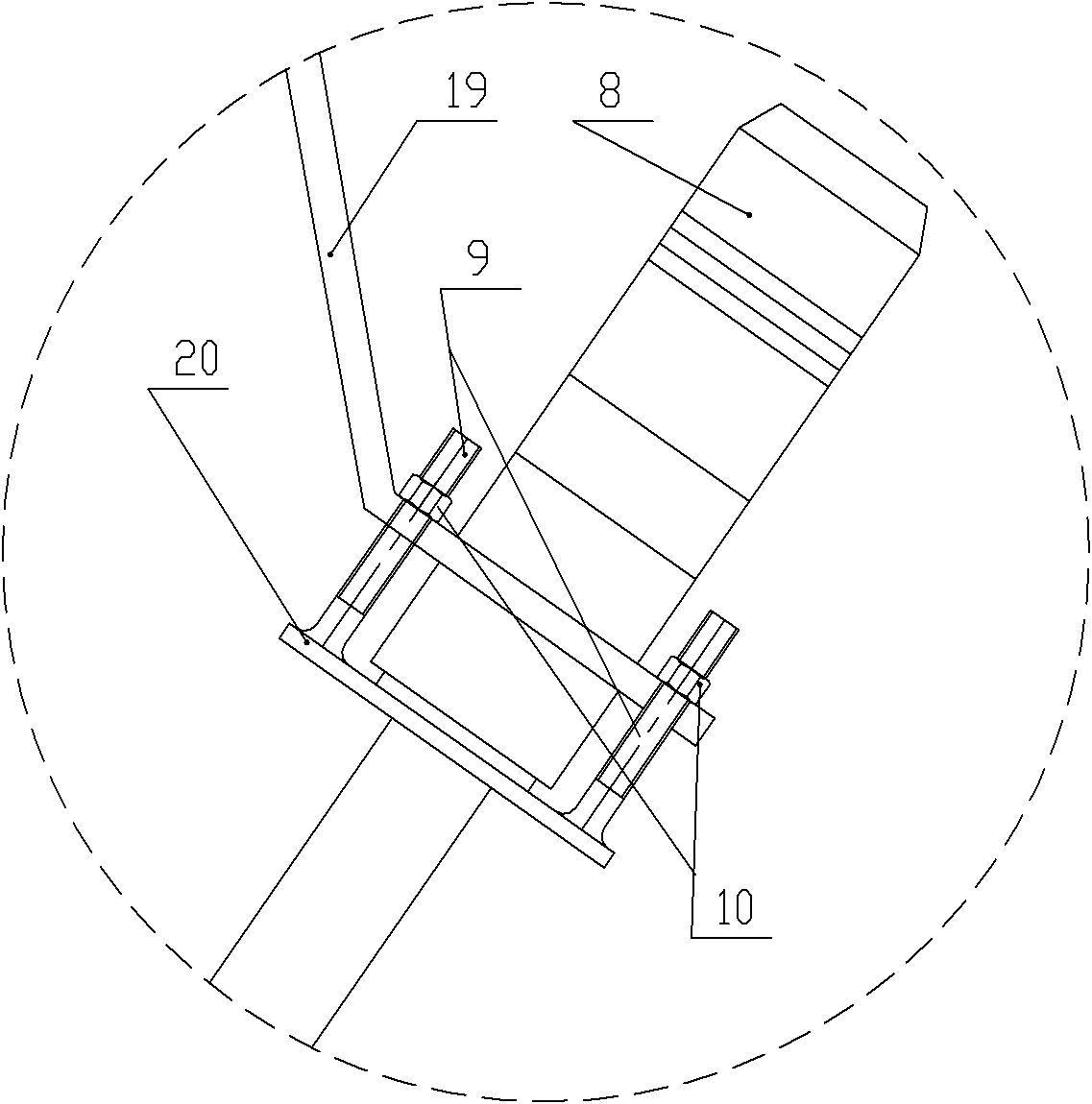

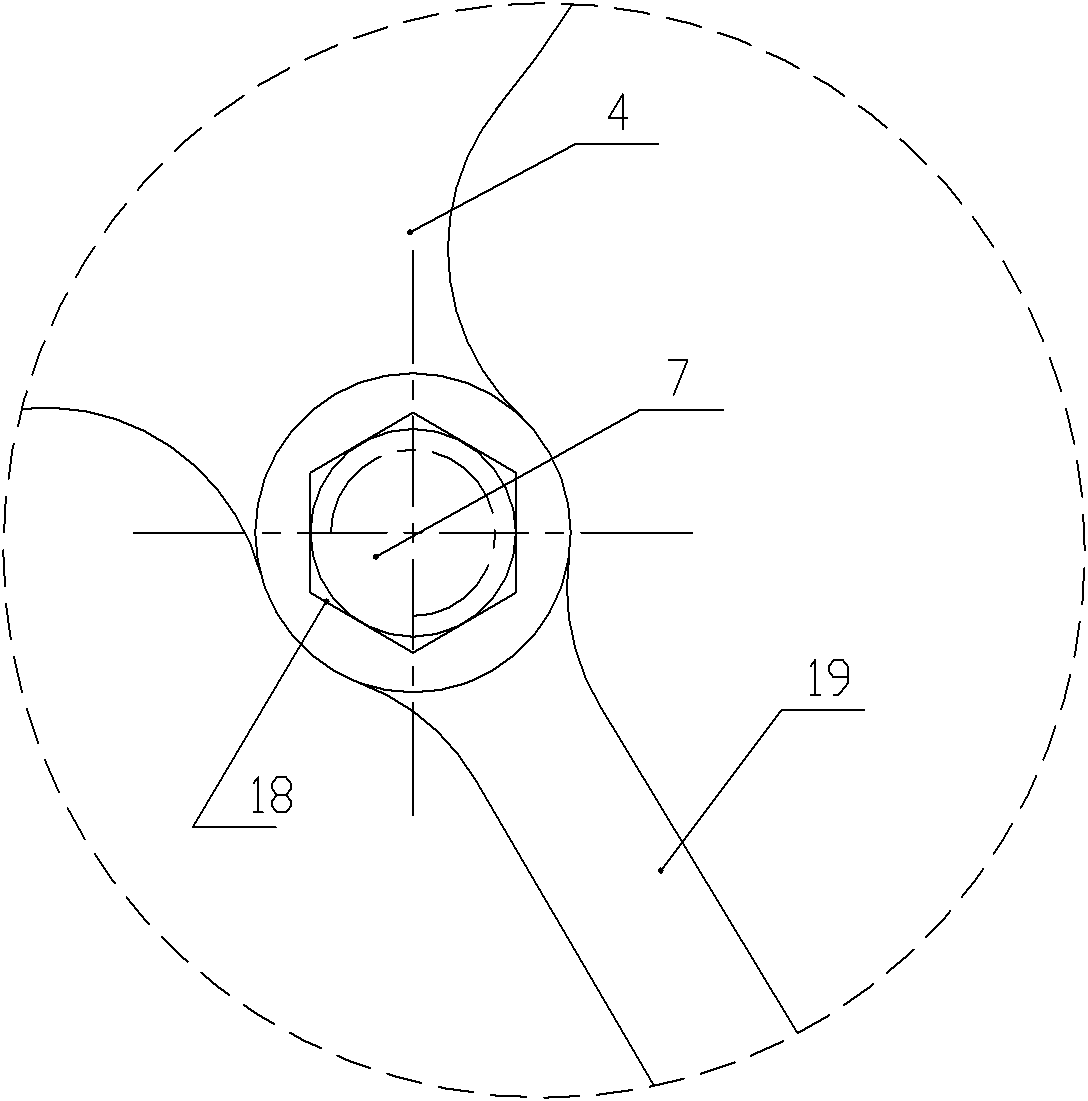

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] see figure 1 , figure 2 and image 3 , the nozzle 11 is installed on the frame body 16 through the nozzle support panel 17, the front box 13 is installed on the front and rear adjustment table 14 on the frame body 16, and the front box ejector rod acting on the front box 13 is installed on the frame body 16 15. There is an aisle 12 connected between the nozzle 11 and the front box 13, and a roller supporting column 1 is installed at the outlet of the casting nozzle 11, and a roller 2 and a beam 3 are installed on the roller supporting column 1, and the front end of the casting nozzle 11 and the casting An ultrasonic generator 8 is installed obliquely in the vertical direction of the rolling direction. The introduction rod of the ultrasonic generator 8 is inserted into the aluminum alloy melt of the nozzle 11. The fixed sleeve 4 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com