High-current metal ion source

A metal ion source and strong current technology, which is applied in the field of ion source and material surface treatment, can solve the problems of average current intensity and injection efficiency limitation, and achieve the effect of increasing divergence and convergence characteristics, improving uniformity, and increasing transmission extraction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

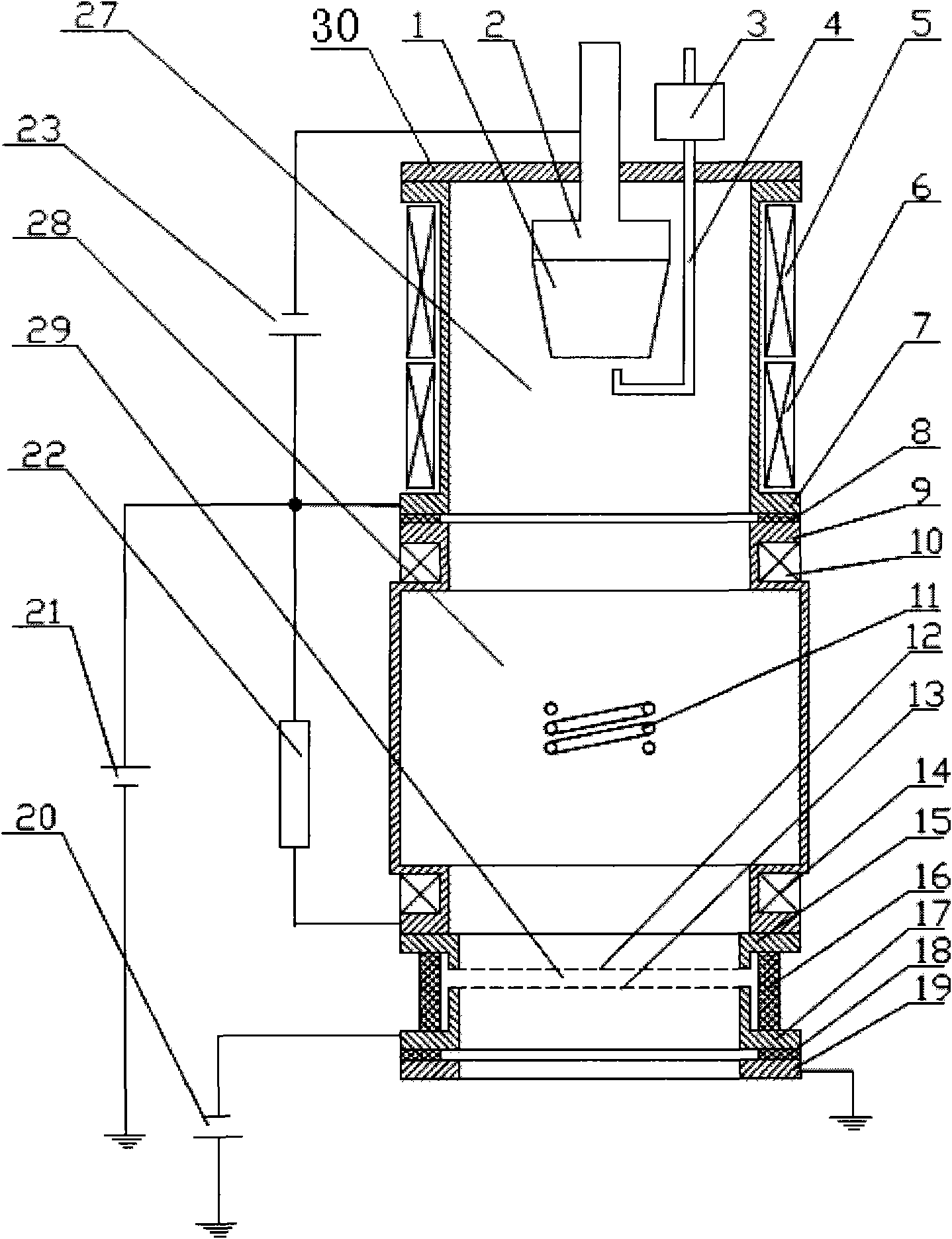

[0021] Such as figure 1 As shown, a high-current metal ion source includes a cathode 1, a water-cooled cathode seat 2, an anode cylinder 7, an arc stabilizing coil 5, a focusing coil 6, a trigger pin 4, a trigger wire package 3, a straight transport tube 9, Divergent coil 10, converging coil 14, insulating ring 8, lead-out grid 12, support flange 15, suppression grid 13, support flange 17, high-voltage insulating ring 16, deceleration power supply 20, acceleration power supply 21, water cooling screw Wire copper pipe 11, deceleration insulating ring 18, grounding flange 19, resistor 22 and arc discharge power supply 23. A groove is formed on the outer wall of the anode cylinder 7, and the arc stabilizing coil 5 and the focusing coil 6 are respectively wound in the groove, and the upper part of the anode cylinder 7 is connected with a flange cover 30 of ceramic material by screws. An inverted "T" shaped water-cooled cathode holder 2 passes through the central axis of the flang...

Embodiment 2

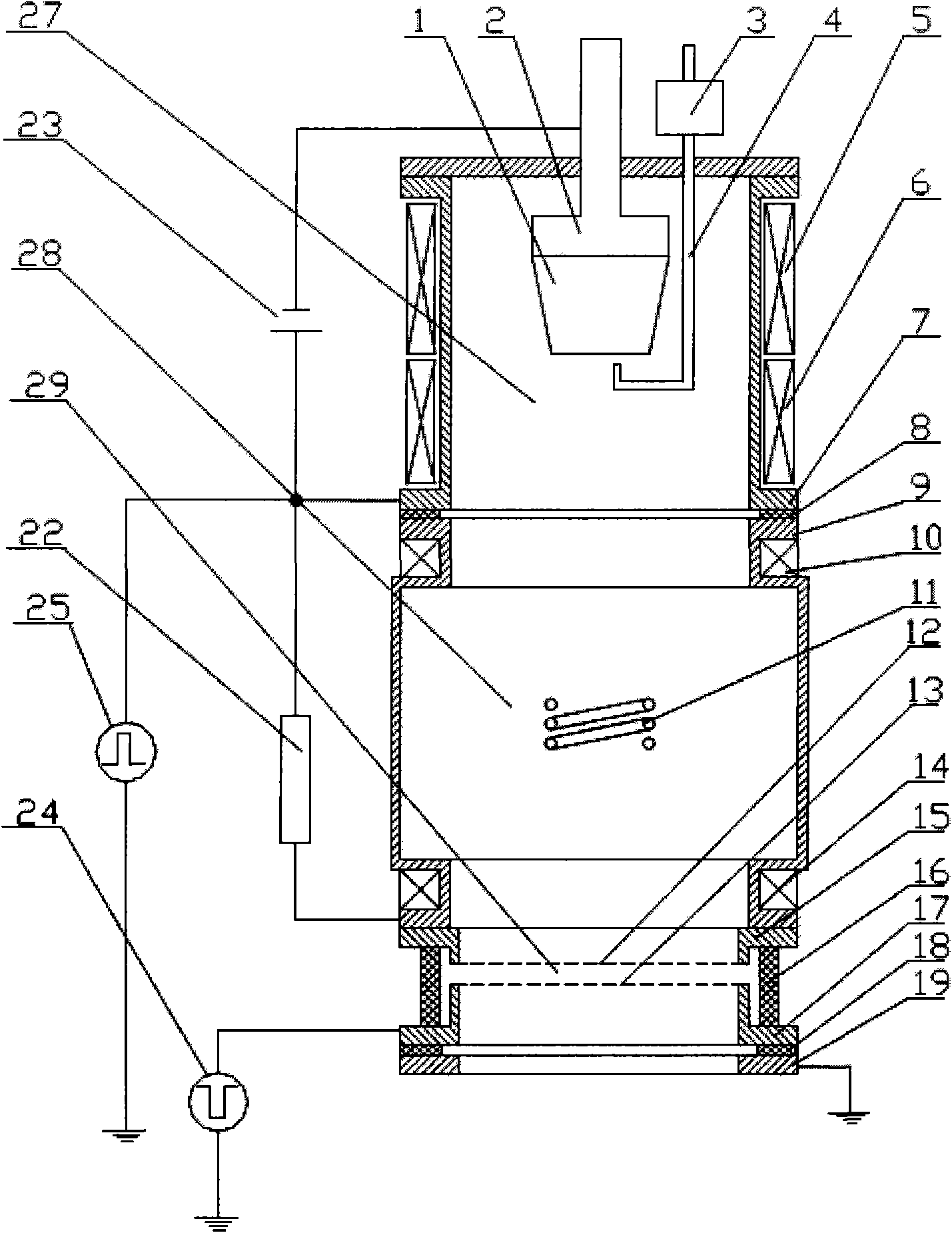

[0024] Such as figure 2 As shown, a high-current metal ion source includes a cathode 1, a water-cooled cathode seat 2, an anode cylinder 7, an arc stabilizing coil 5, a focusing coil 6, a trigger pin 4, a trigger wire package 3, a straight transport tube 9, Divergent coil 10, converging coil 14, insulating ring 8, lead-out grid 12, support flange 15, suppression grid 13, support flange 17, high-voltage insulating ring 16, deceleration power supply 20, acceleration power supply 21, water cooling screw Wire copper pipe 11, deceleration insulating ring 18, grounding flange 19, resistor 22 and arc discharge power supply 23. There is a groove on the outer wall of the anode cylinder 7, and the arc stabilization coil 5 and the focus coil 6 are respectively wound in the groove, and the upper part of the anode cylinder 7 is connected with a flange of ceramic material by screws. Cover 30. An inverted "T" shaped water-cooled cathode holder 2 passes through the central axis of the flan...

Embodiment 3

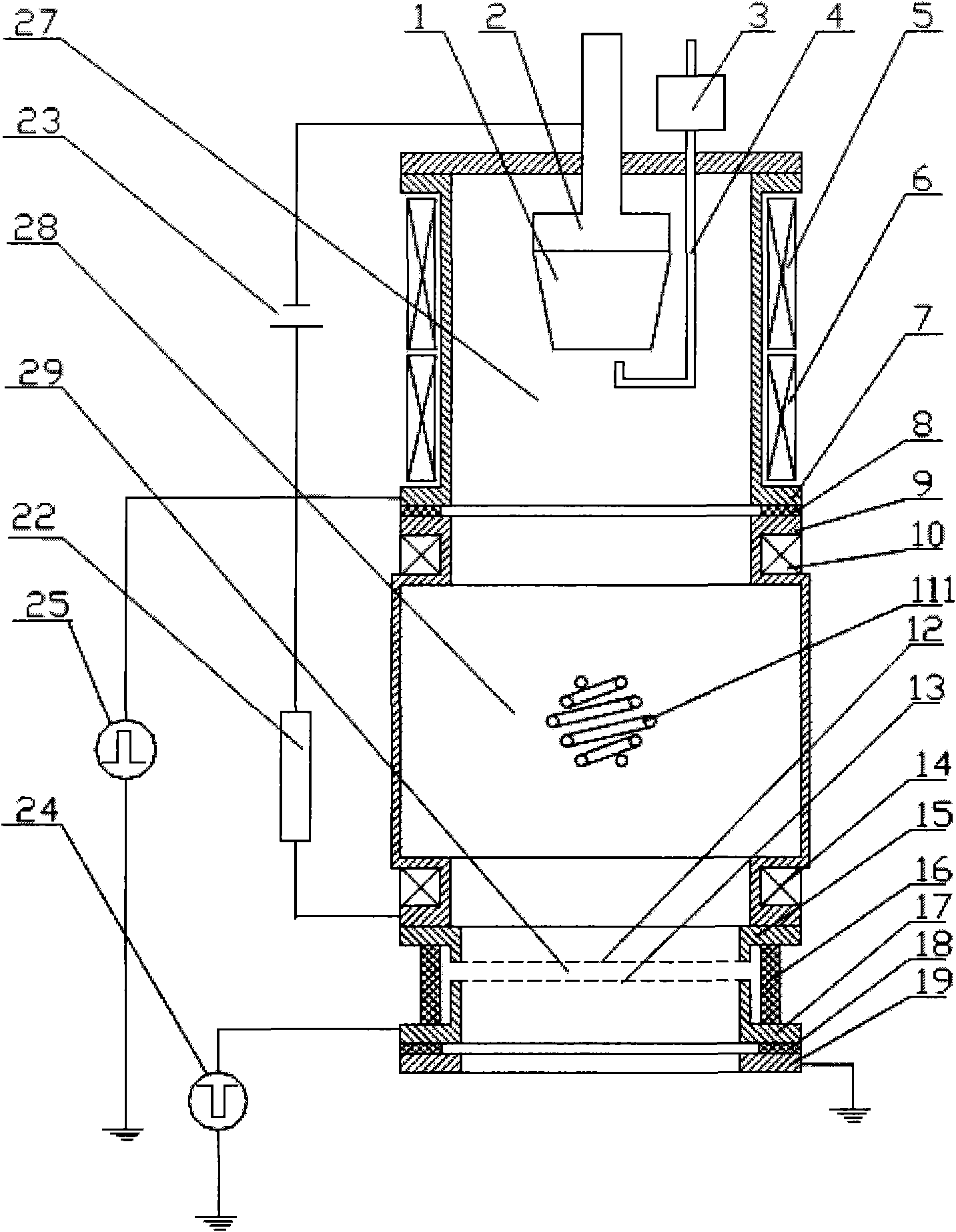

[0026] Such as image 3 As shown, a high-current metal ion source includes a cathode 1, a water-cooled cathode seat 2, an anode cylinder 7, an arc stabilizing coil 5, a focusing coil 6, a trigger pin 4, a trigger wire package 3, a straight transport tube 9, Divergent coil 10, converging coil 14, insulating ring 8, lead-out grid 12, support flange 15, suppression grid 13, support flange 17, high-voltage insulating ring 16, deceleration power supply 20, acceleration power supply 21, water cooling screw Wire copper pipe 11, deceleration insulating ring 18, grounding flange 19, resistor 22 and arc discharge power supply 23. A groove is formed on the outer wall of the anode cylinder 7, and the arc stabilizing coil 5 and the focusing coil 6 are respectively wound in the groove, and the upper part of the anode cylinder 7 is connected with a flange cover 30 of ceramic material by screws. An inverted "T" shaped water-cooled cathode holder 2 passes through the central axis of the flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com