Sulfuric acid washing corrosion-retarding fog inhibitor and preparation method thereof

A sulfuric acid pickling and fog inhibitor technology, applied in the field of chemical anticorrosion, can solve the problems of small corrosion inhibition rate, human health impact, large consumption, etc., to protect the matrix metal, reduce the number of hydrogen atoms, and reduce the electrode reaction. slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

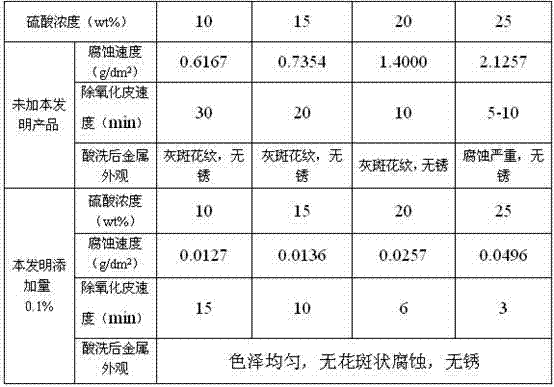

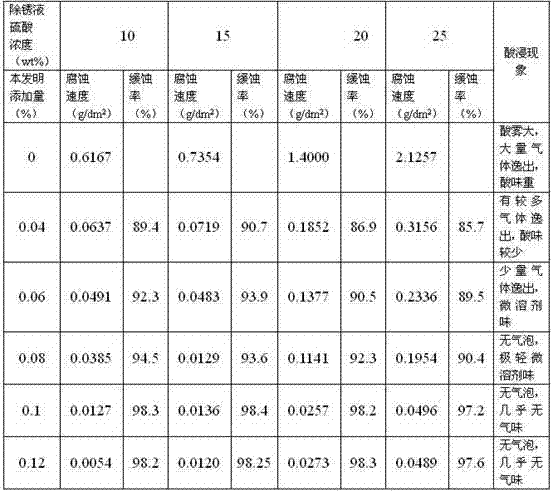

Examples

Embodiment 1-6

[0034] Embodiments 1-6 of the present invention: the components of the present invention include inhibitors, complexing agents and wetting agents, and the inhibitors include di-o-tolylthiourea, o-toluene, sulfonated proteins and ethylenediaminetetraacetic acid, complexing The agents include sodium citrate, sodium tartrate, hydroxyacetic acid and gallic acid, and the wetting agents include sodium sulfonate, sodium carboxylate, L-548 and OP-10, and their weight percentages are as follows (%):

[0035]

[0036] The preparation method of this sulfuric acid pickling anti-corrosion and anti-fogging agent:

[0037] a. Put o-methylaniline in a three-port reactor, slowly add sulfonated protein, di-o-tolylthiourea and ethylenediaminetetraacetic acid under stirring, control the temperature at 60-70°C, and stir for 0.5-1.5 hours until Orange (take a sample of 10ml and put it into a 20ml test tube to compare with the standard colorimetric test tube) until the colloid is formed.

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com