Annular cylinder rotor engine

A rotary engine and rotor technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of low torque, weak durability, and materials are easily corroded, and achieve fewer parts, easy production and manufacturing, and energy conversion. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] 1. Various components of the ring cylinder rotary engine

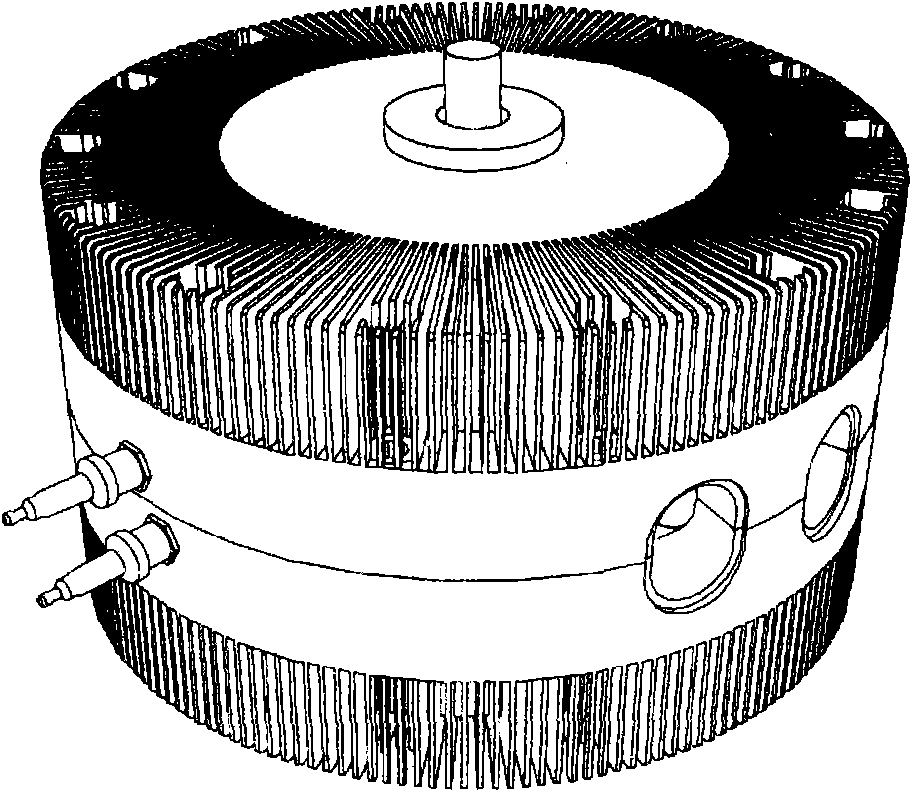

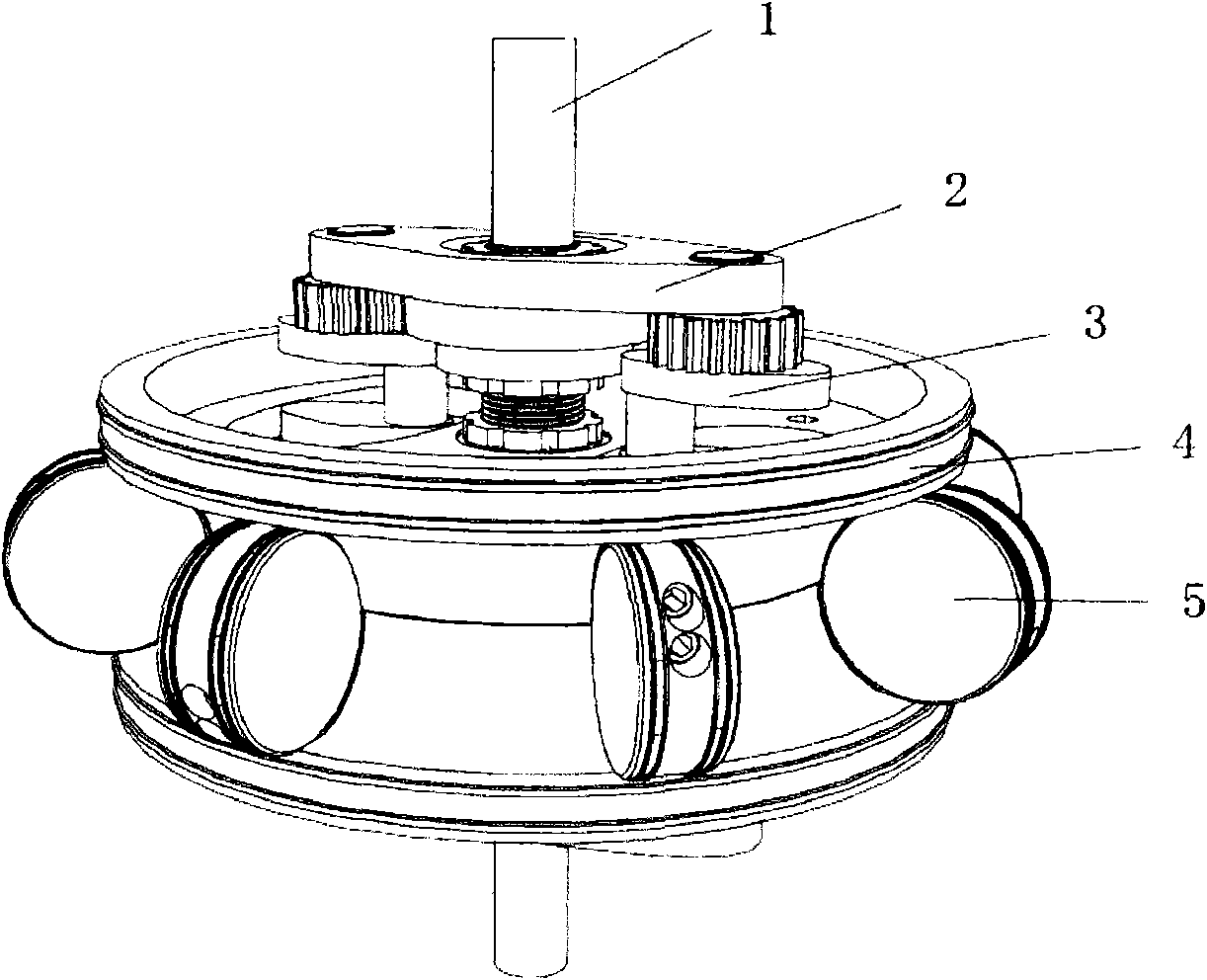

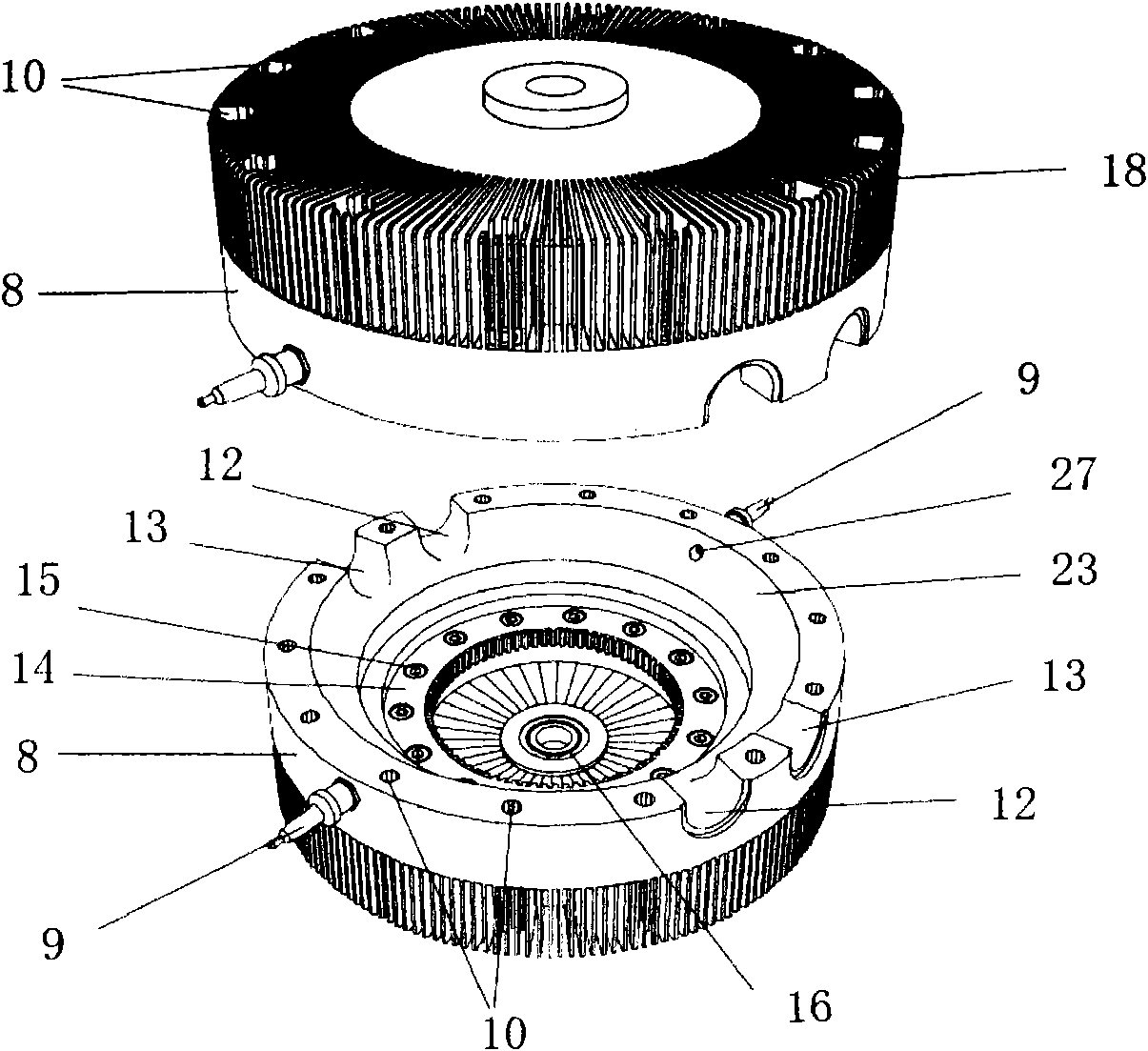

[0059] like figure 1 , 2 , Shown in 3, 4, this engine is made up of rotor assembly, stator assembly, annular combustion chamber three parts. figure 1 for the complete engine, figure 2 for the rotor assembly, image 3 for the stator assembly, Figure 4 The annular combustion chamber cavity between the rotor assembly and the stator assembly can be seen. like Figure 5 As shown, the inside of the whole machine is divided into two systems by the sealing ring, the drive train (24) is closed in the inner center to form a cylinder, the combustion system (25) surrounds the drive train (24), and the rotor annular outer wall (22) and The donut-shaped annular cavity that housing annular inner wall (23) forms is both. Cooling system (26) is formed by the cooling fins (18) outside the casing at the outside of the complete machine.

[0060] like Figure 10 As shown, the components constituting the rotor assembly inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com