Heat regenerative liquid fuel micro-burner

A technology of liquid fuel and micro-combustor, which is applied in the field of micro-energy systems, can solve the problem of liquid fuel ignition, exhaust heat loss is difficult to be solved well, and achieve the effects of not being easy to extinguish, realizing waste heat utilization, and stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

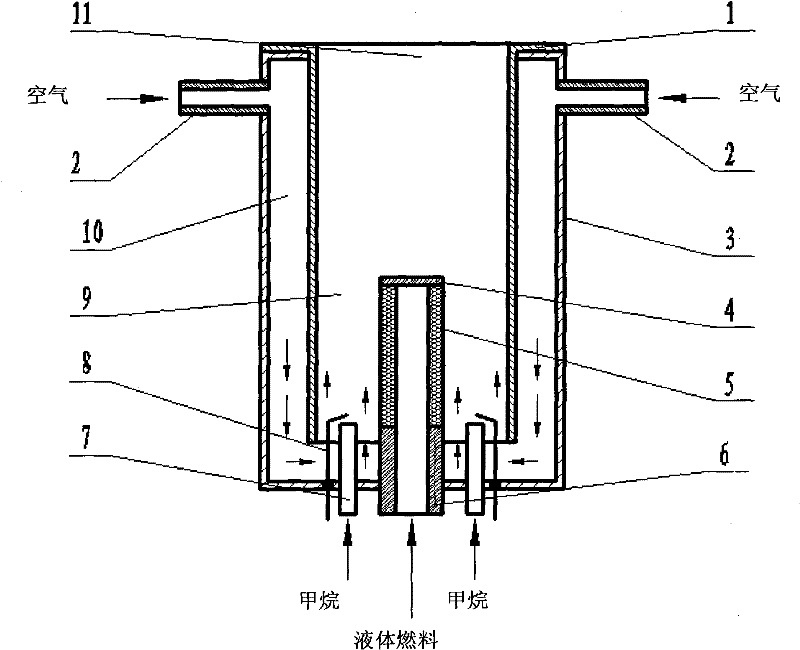

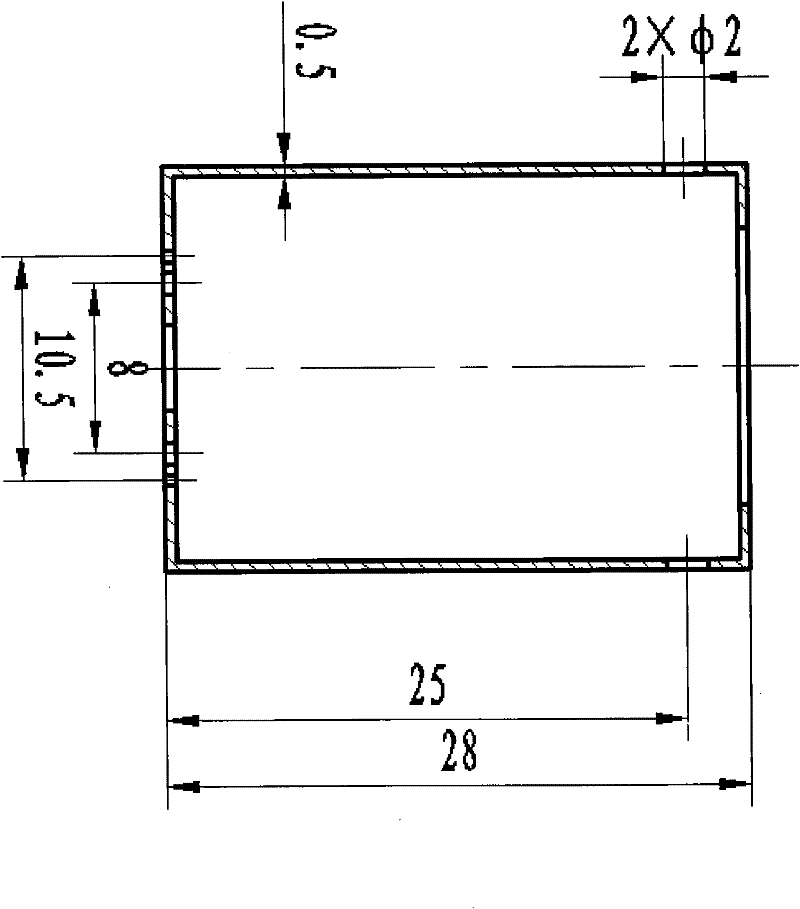

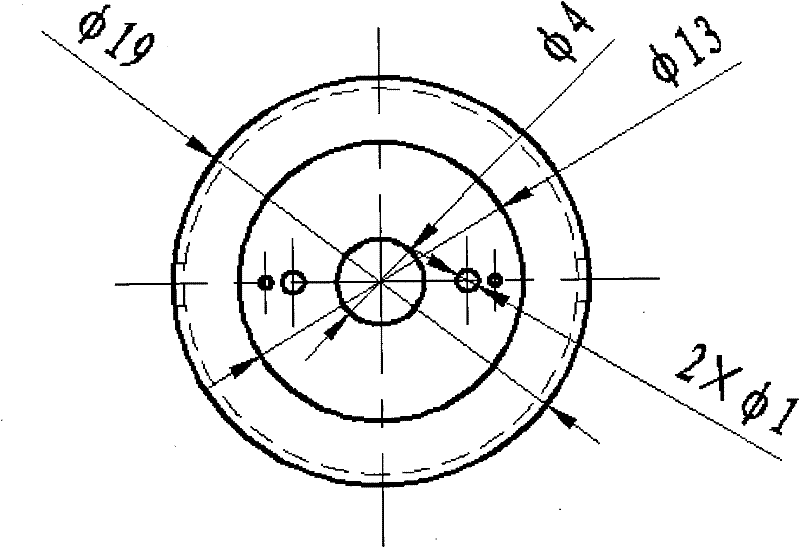

[0031] Such as figure 1 As shown, a recuperative liquid fuel micro burner includes an exhaust outlet 11, an outer cylinder 3, an inner cylinder 1, an air nozzle 2, a combustion chamber 9, an igniter 8, a methane gas nozzle 7 and a liquid fuel The nozzle 6 also includes an annular space 10 between the inner cylinder 1 and the outer cylinder 3, and a porous medium atomizing pipe 5 welded and fixed on the liquid fuel nozzle 6; the bottom of the annular space 10 communicates with the combustion chamber, and the air can Pass through the bottom of the inner cylinder 1 and enter the combustion chamber 9, and the top end is welded and sealed with the sealing cover plate 4. The air nozzles 2 are symmetrically arranged on both sides of the burner outer cylinder 3 , and the methane gas nozzles 7 are symmetrically arranged on both sides of the liquid fuel nozzle 6 . The cross sections of the inner cylinder 1, the air nozzle 2, the burner outer cylinder 3, the porous medium atomizing pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com