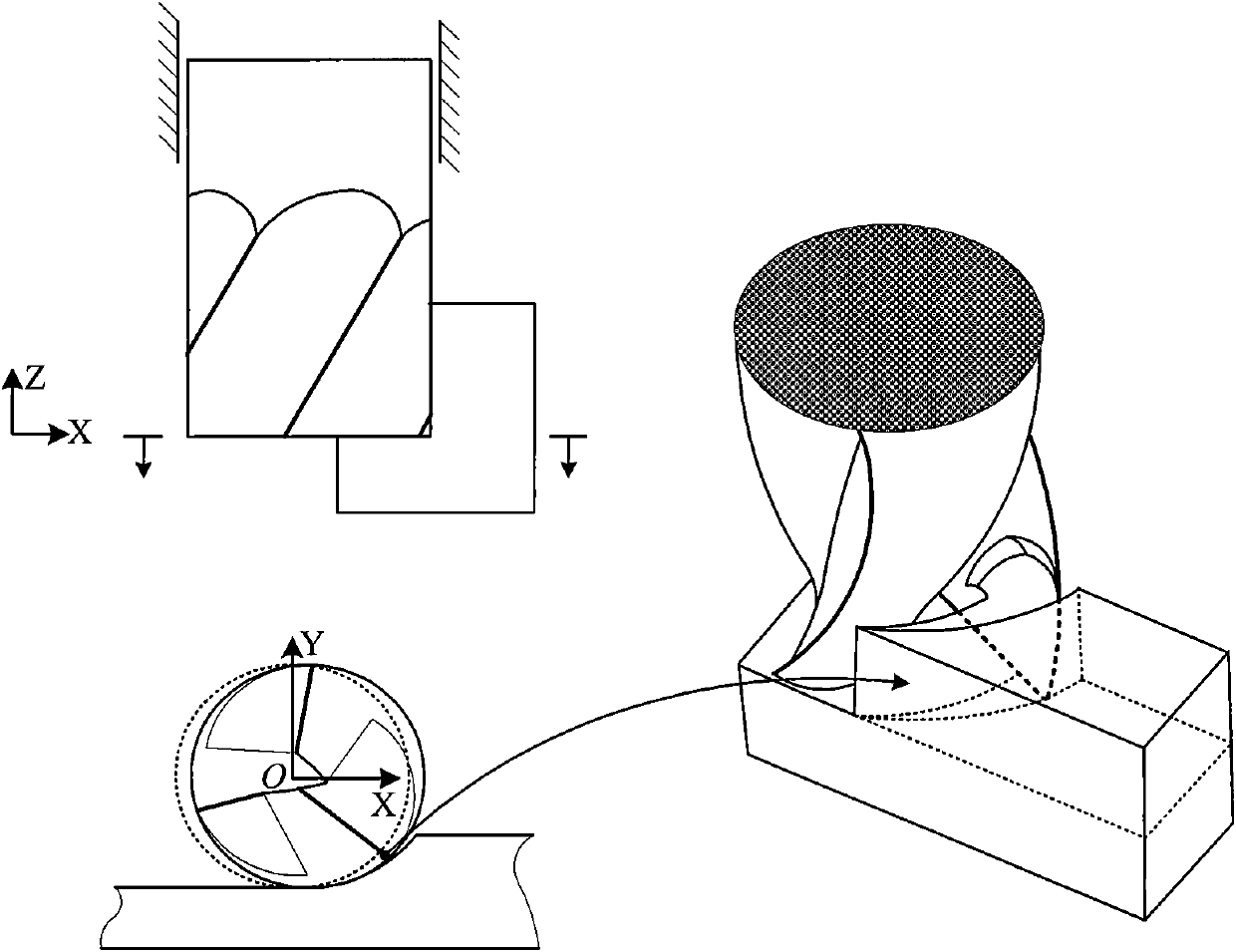

Method for modeling milling force in peripheral milling process

A modeling method and milling force technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of poor prediction accuracy of milling force models, and achieve the effect of saving test costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

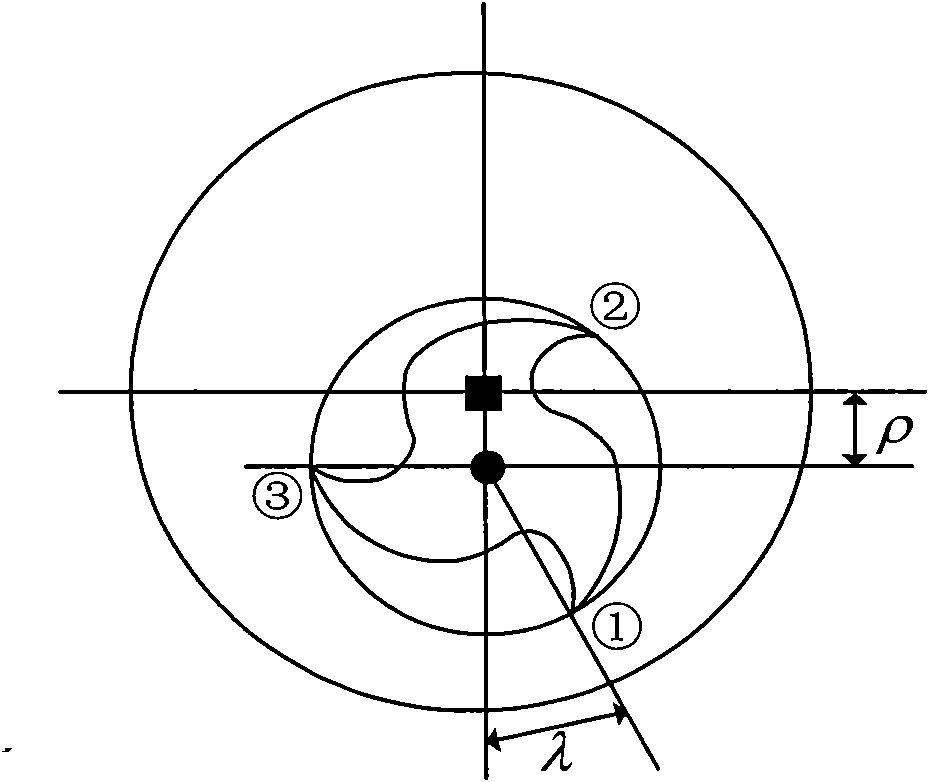

[0093] Embodiment 2: Select radius R=6mm, helix angle β. The three-tooth carbide end mill with =30° performs down-milling on aluminum alloy A17050 on a three-coordinate numerical control end milling machine. Predicted radial depth of cut R r =5mm, axial depth of cut R z = 3mm, single tooth feed rate f = 0.08mm, spindle speed v = 1000r / min, the steps of the milling force during the down milling cutting process are as follows:

[0094] (1) Select the radial depth of cut R r =6mm, axial depth of cut R z = 5mm, single tooth feed f = 0.06mm, spindle speed v = 1000r / min, carry out the calibration test.

[0095] (2) Taking the axial differential beam segment as 1mm, the corresponding sampling interval is 5.5°. Test and record milling forces Depend on Solutions have to: adopt because it is relatively and larger.

[0096] (3) will be solved Substituting the expression of the actual cutting radius of the blade, expanding and organizing according to the trigonome...

Embodiment 3

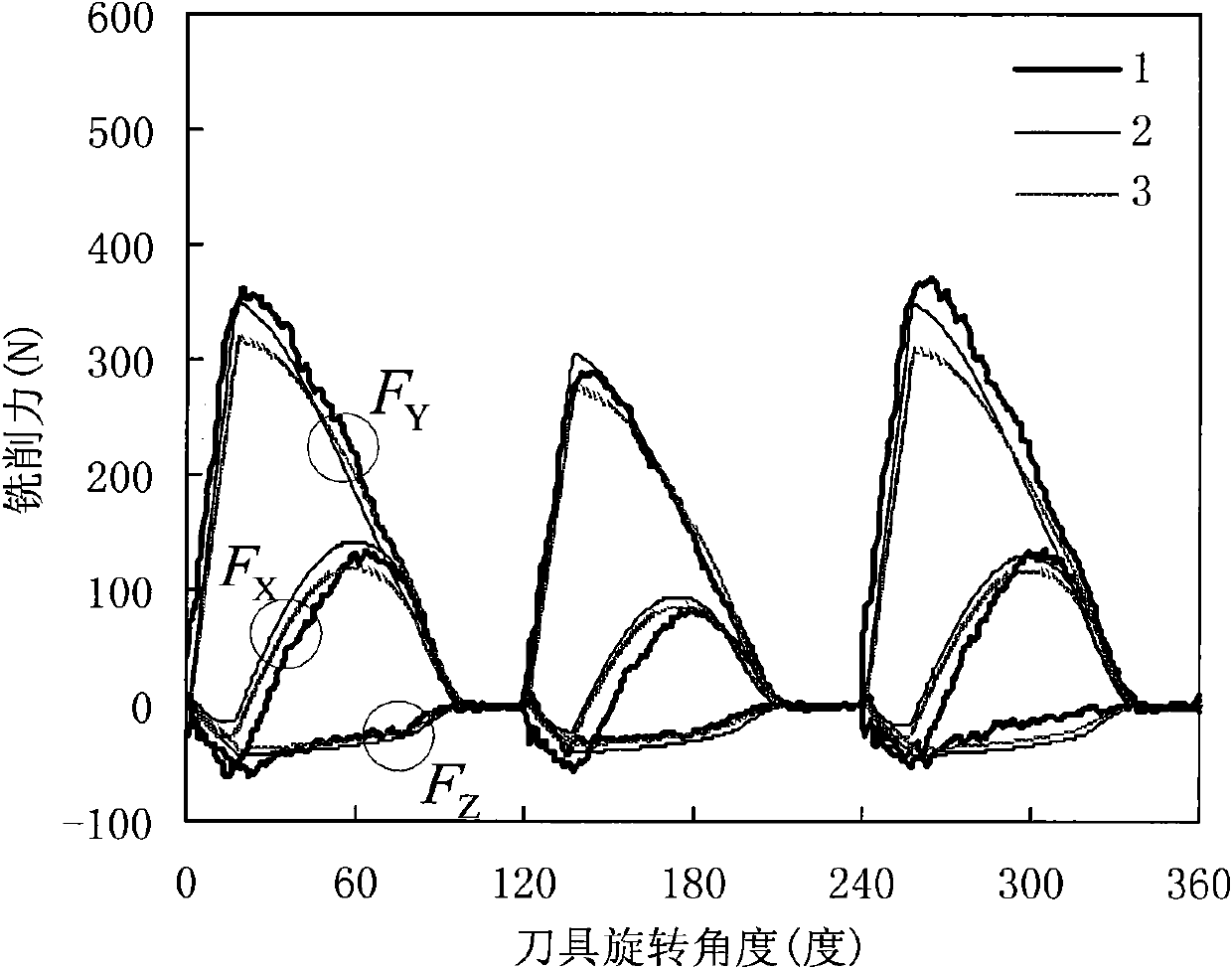

[0110] Embodiment 3: Using the cutting tool and machine tool in Embodiment 2 to mill aluminum alloy Al7050, predict the radial depth of cut R r =12mm, axial depth of cut R z = 3mm, single tooth feed rate f = 0.022mm, spindle speed v = 3000r / min milling force in the down milling cutting process.

[0111] Bring the calibration results of Example 2 into the basic milling force model to predict the milling force. From Figure 4 It can be seen from the prediction results of the milling force that the prediction accuracy of the milling force in the peripheral milling process is improved by adopting the modeling method of this embodiment.

[0112] It should be pointed out that once the tool is re-installed during machining, the previously calibrated milling force coefficient can continue to be used, but the tool eccentricity parameter must be re-calibrated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com