Synthesis method for ciclesonide

A synthesis method, the technology of cyclohexyl formaldehyde, is applied in the field of ciclesonide synthesis, which can solve the problems of complex post-processing, etc., and achieve the effects of convenient post-processing, less waste, and high efficiency

Inactive Publication Date: 2010-10-13

无棣鑫岳化工集团有限公司

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The post-reaction processing is more complex

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

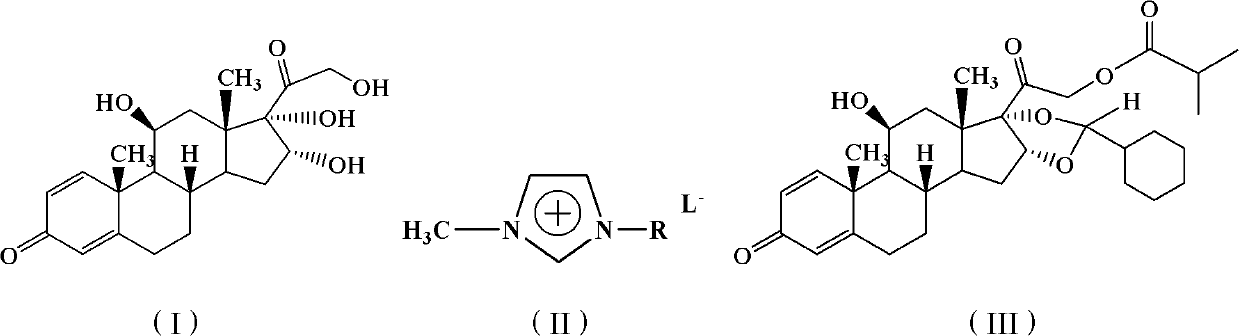

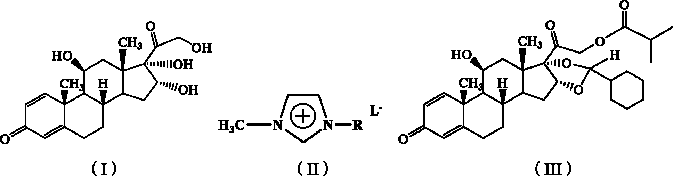

The invention discloses a synthesis method for ciclesonide with a structure shown as the formula (III). The synthesis method adopts 16 Alpha-hydroxyprednisolone as material with a structure shown as the formula (I) and acidic ionic liquid as solvent and catalyst with a structure shown as the formula (II), and includes the following specific steps that: the 16Alpha-hydroxyprednisolone, isobutyricanhydride, cyclohexanal and the acidic ionic liquid are added into a reaction container together, and react under the temperature condition of 10 DEG C to 100 DEG C, and after sufficient reaction, the obtained reaction liquid is postprocessed, so that the ciclesonide product is obtained. Since the invention adopts the acidic ionic liquid as solvent and catalyst and a one-pot method for preparation, the technique has the advantages of easy operation, high capacity, high efficiency, less three wastes and convenient postprocessing, the ionic liquid can be reused, and therefore the technique is an economic, practical and environment-friendly technique.

Description

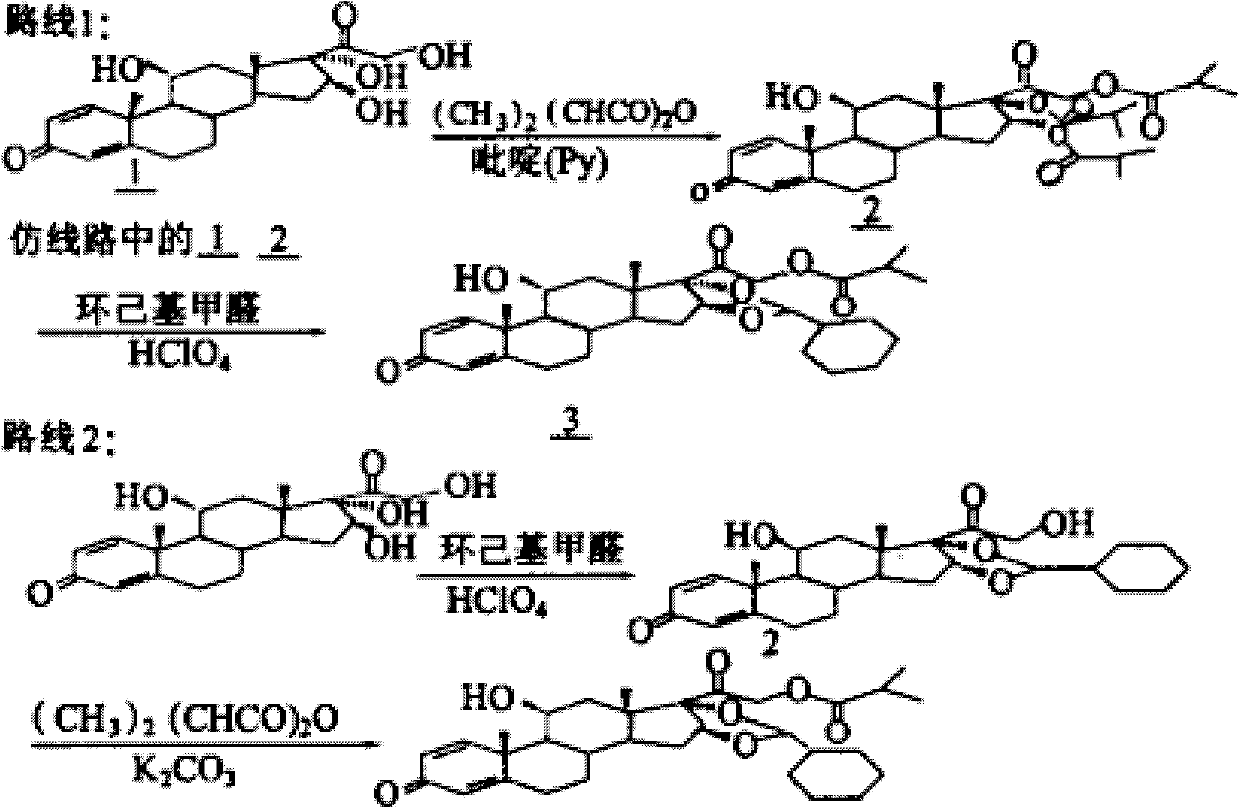

(1) Technical field The invention relates to a synthesis method of ciclesonide. (2) Background technology Ciclesonide, English name: (11β, 16α)-16, 17-[[(R)-Cyclo-hexylmethylene]bis(oxy)]11-hydroxy2-21-(2-methyl-1-oxo -propoxy)pregna-1, 4-diene-3, 20-dione. Chemical formula: C 32 h 44 o 7 , Molecular weight: 540. It is a drug for the treatment of asthma, an inhaled glucocorticoid with a new release and distribution mechanism, which can relieve the inflammation of the lungs and airways of patients. The synthetic routes of ciclesonide reported in the literature mainly contain the following two: Above-mentioned synthetic route is all to be raw material with 16α-hydroxy prednisolone, just process order is different, with perchloric acid as reaction catalyst, reacts with 2,2-dimethoxypropane to generate corresponding acetonylidene product; Then cyclo Hexanaldehyde reaction, and then reacted with isobutyric anhydride under the effect of potassium carbonate to generate th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07J71/00

CPCY02P20/54

Inventor 裴文郑洁孙莉杨培风胡香凝丁茂华

Owner 无棣鑫岳化工集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com