Low gravity center three-axle spiral drilling machine and drilling method thereof

A technology of auger drilling rig and low center of gravity, which is applied to drilling equipment and methods, rotary drilling rigs, rotary drilling, etc. It can solve the problems of high center of gravity of auger drilling rigs and high center of gravity of drilling rigs, so as to increase construction depth and reduce overall weight , the effect of reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

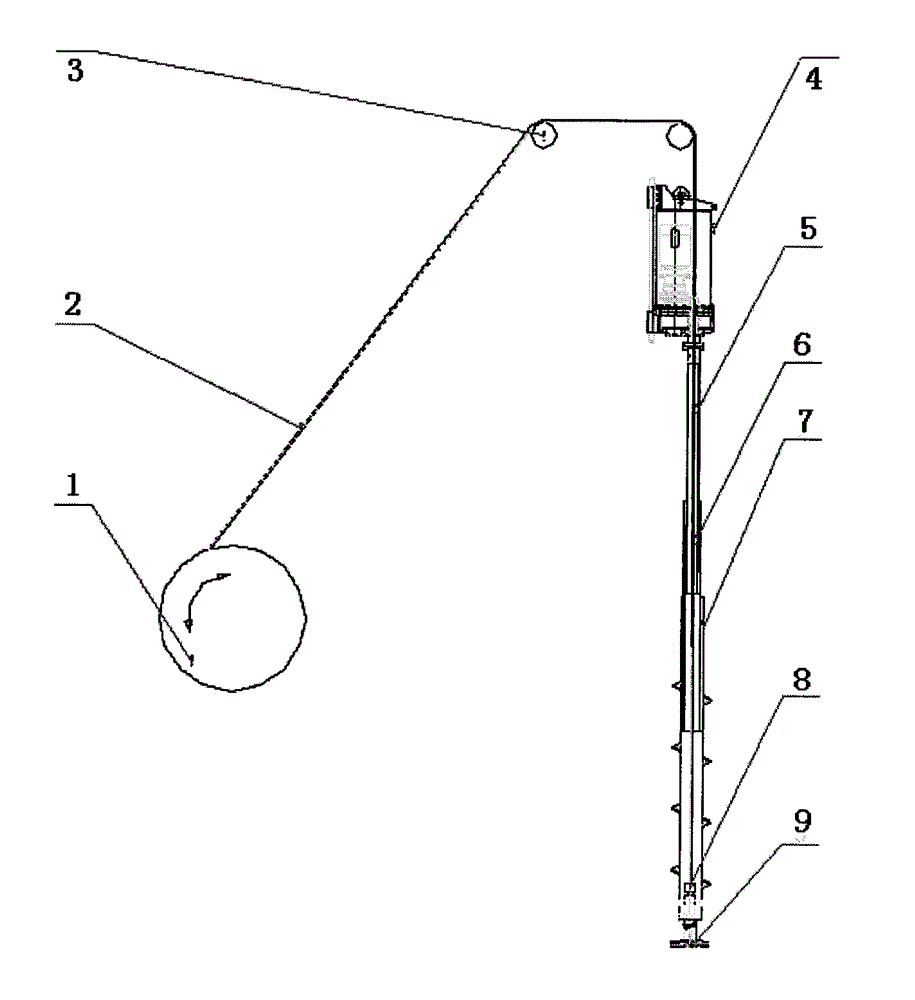

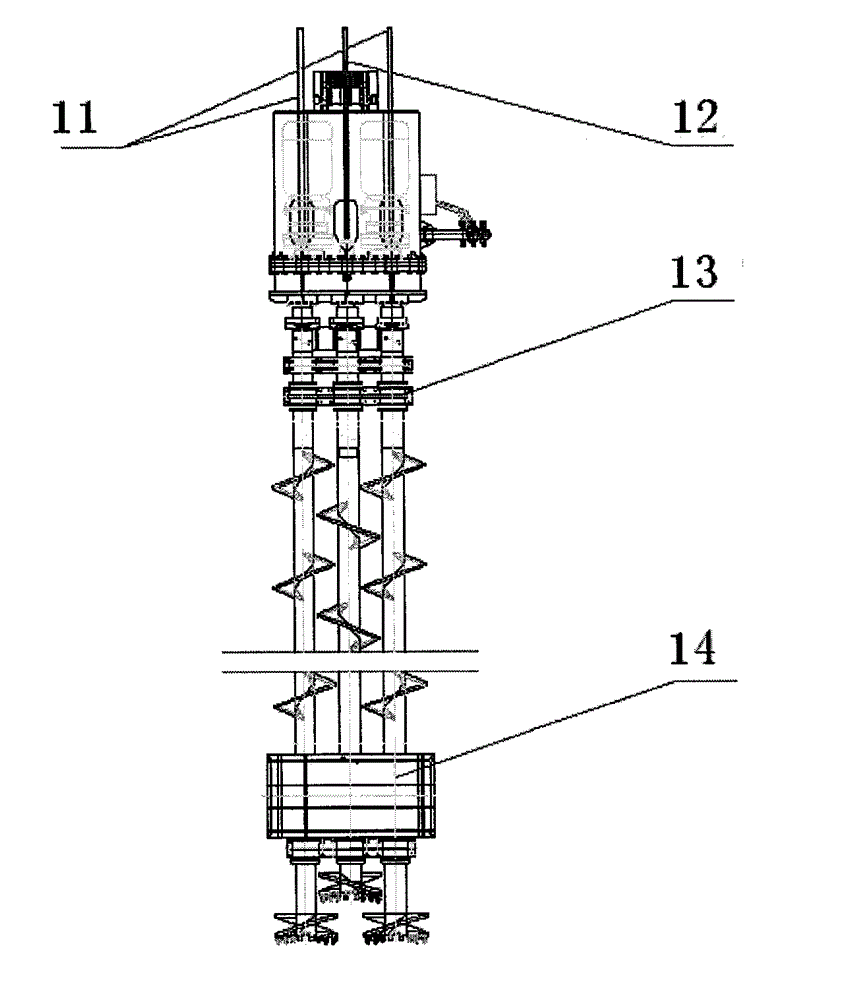

[0025] see figure 1 and figure 2 , the low-center-of-gravity three-axis auger drill of the present invention includes a body (not shown), a rubber tube winding frame 1, a rubber tube 2, a rubber tube guide wheel 3, a drilling power head 4, a third telescopic drill rod 5, a first The two-section telescopic drill pipe 6, the first helical telescopic drill pipe 7, the rotary joint 8, and the helical drill bit 9 are composed of a rubber tube winding frame 1, a rubber tube guide wheel 3, and a drilling power head 4 installed on the body; the third Sectional telescopic drill pipe 5, second telescopic drill pipe 6, and first section helical telescopic drill pipe 7 jointly form a telescopic telescopic combined drill pipe, wherein the telescopic combined drill pipe can also be two sections or four Sections and other different combinations, preferably three sections in this embodiment, are fixed by joint pins between the telescopic drill rods, and are positioned by joint pins when ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com