Anti-clogging coal-fired industrial furnace

A technology for slag-burning coal and kilns, applied in the field of industrial kilns, can solve the problems of low efficiency, serious slagging and high NOx emission, and achieve the effects of solving slag formation in the furnace, improving the efficiency of the kiln and reducing the temperature of the furnace chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

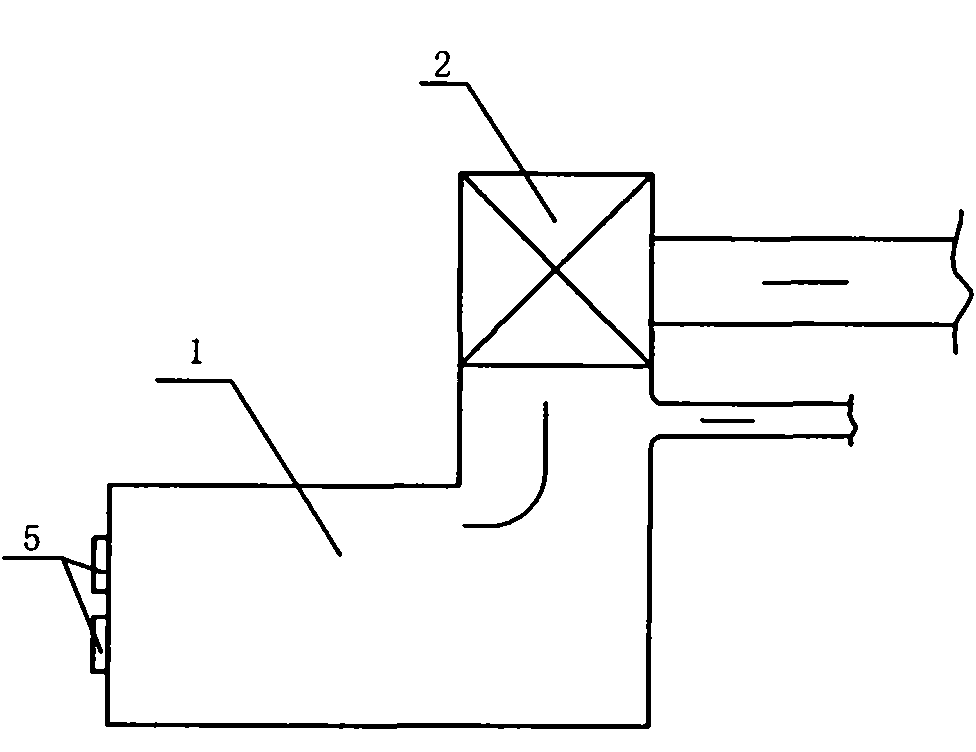

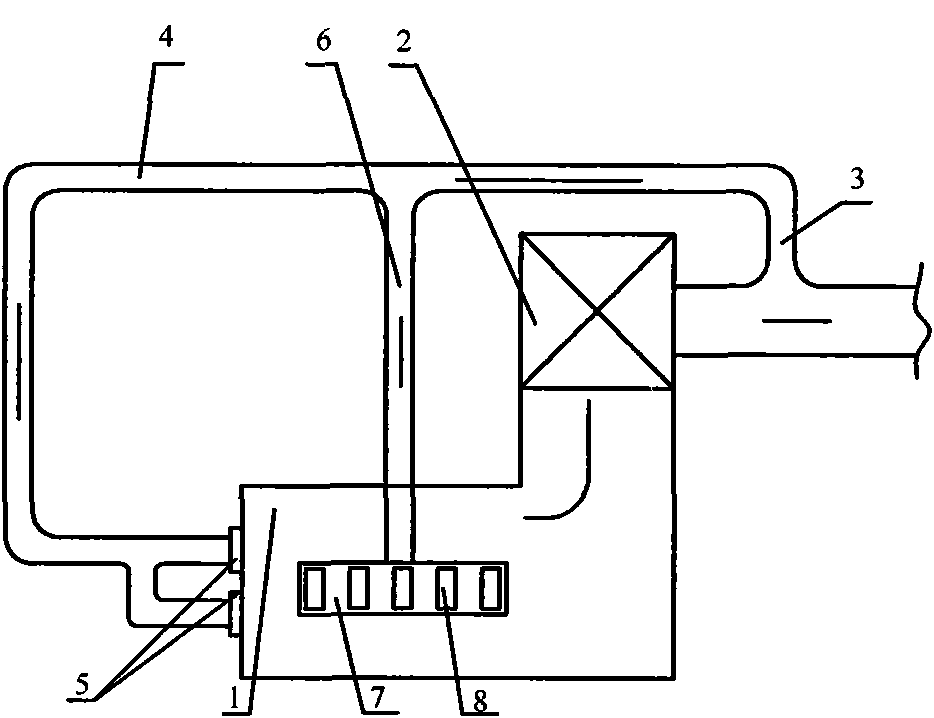

specific Embodiment approach 1

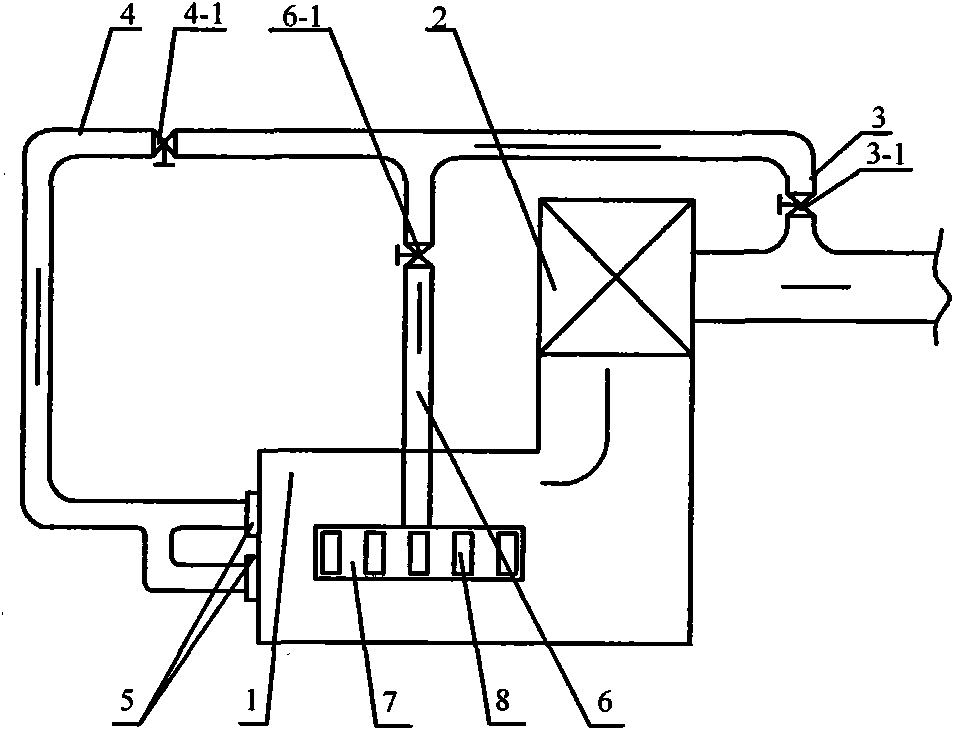

[0008] Specific embodiment one: combination figure 2 with image 3 To illustrate this embodiment, the kiln of this embodiment includes an adiabatic furnace 1 and a flue gas utilization device 2. The kiln also includes a flue gas recirculation main pipe 3, a first flue gas recirculation sub-pipe 4, and a set of smoke The cyclone pulverized coal burner 5 for gas recirculation, the second flue gas recirculation sub-pipe 6, and a set of flue gas recirculation nozzles 8, the outlet of the adiabatic furnace 1 is connected to the flue gas utilization equipment 2, and the flue gas utilization equipment The outlet of 2 is connected to the inlet of the flue gas recirculation main pipe 3, and the outlet of the flue gas recirculation main pipe 3 is respectively connected to the inlet of the first flue gas recirculation sub-pipe 4 and the inlet of the second flue gas recirculation sub-pipe 6 , The outlet of the first flue gas recirculation sub-pipe 4 is in communication with the correspondi...

specific Embodiment approach 2

[0009] Specific implementation manner two: combination image 3 To explain this embodiment, the kiln of this embodiment also includes a flue gas recirculation main baffle 3-1. The flue gas recirculation main pipe 3 is equipped with a flue gas recirculation main baffle 3-1. This structure can be controlled The amount of recirculated flue gas thus controls the inlet flue gas temperature and furnace temperature of the flue gas utilization device 2. Other components and connection relationships are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination image 3 To explain this embodiment, the kiln of this embodiment further includes a first flue gas recirculation baffle 4-1, and the first flue gas recirculation sub-pipe 4 is equipped with a first flue gas recirculation baffle 4-1, This structure can control the amount of recirculated flue gas leading to a set of swirling pulverized coal burners 5 with flue gas recirculation. Other components and connection relationships are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com