Grinding type optical fiber polarizer based on photonic crystal fiber

A photonic crystal fiber and polarization device technology, applied in the coupling of optical waveguides, etc., can solve the problems of complex manufacturing process and large size, and achieve the effects of high extinction ratio, small size, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

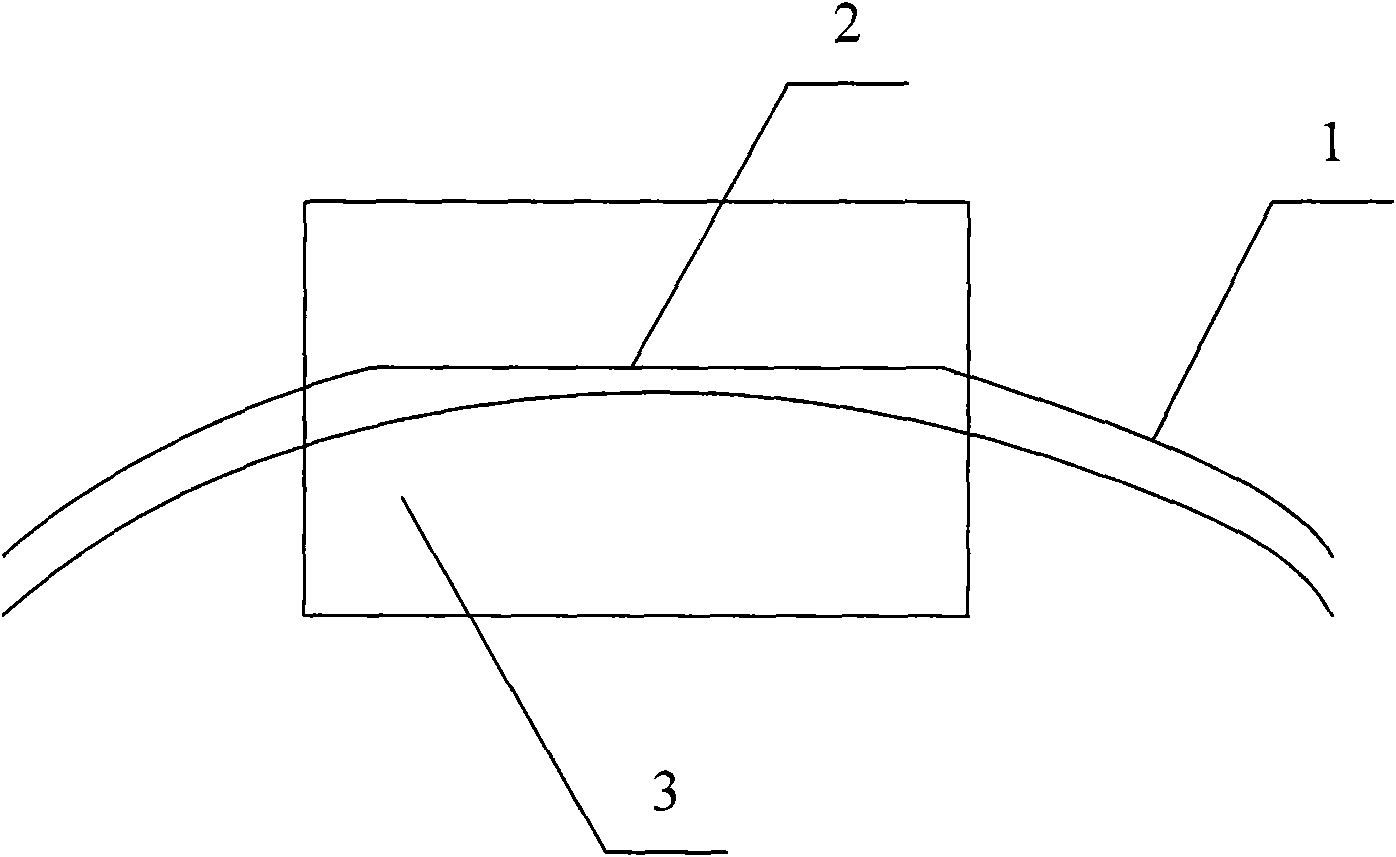

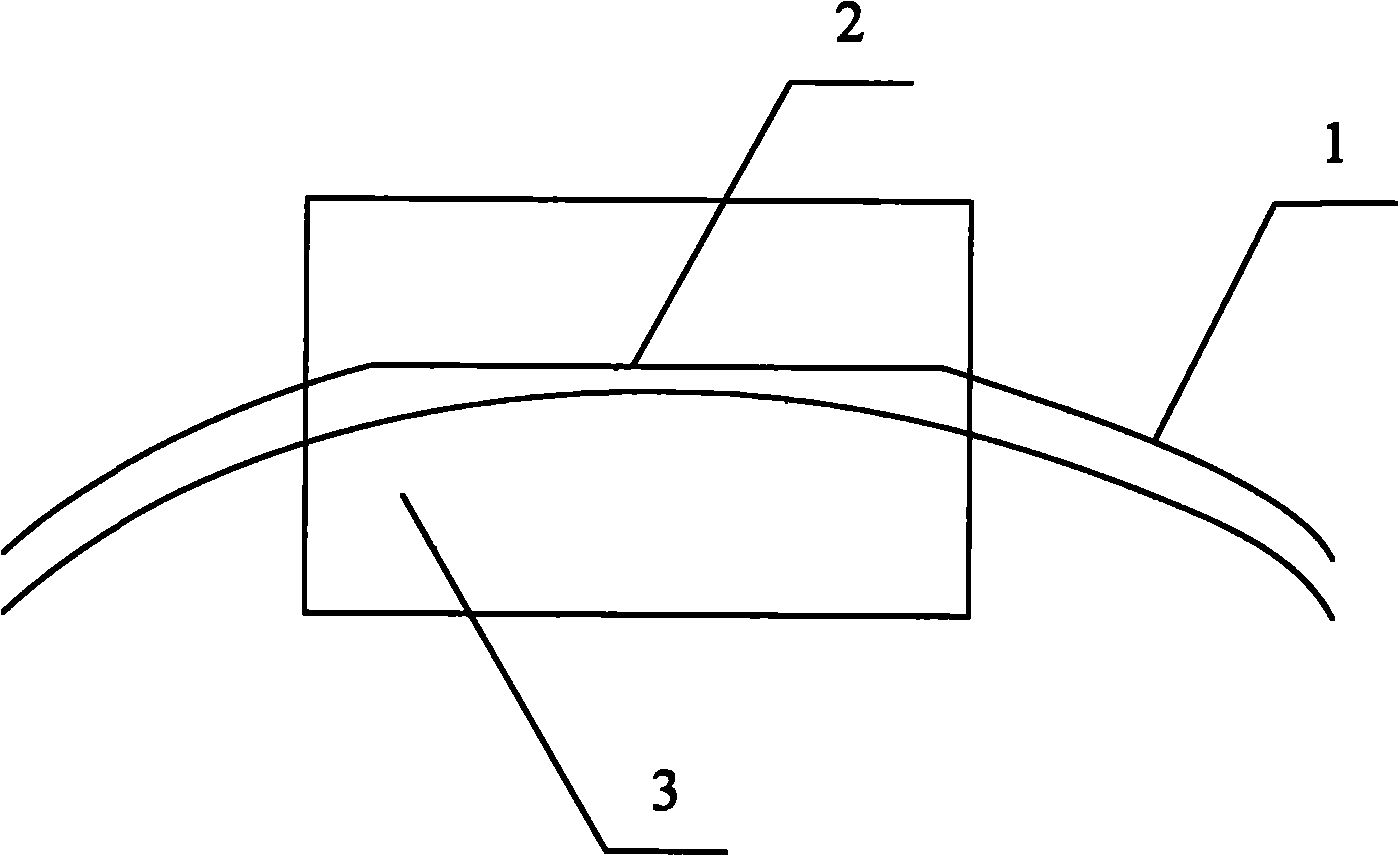

[0015] like figure 1 As shown, a photonic crystal fiber-based ground fiber polarization device includes a photonic crystal fiber 1 and a fixing plate 3 . Polishing is performed on the side of the photonic crystal fiber 1 , and the polished part 2 of the photonic crystal fiber is pasted on the fixing piece 3 .

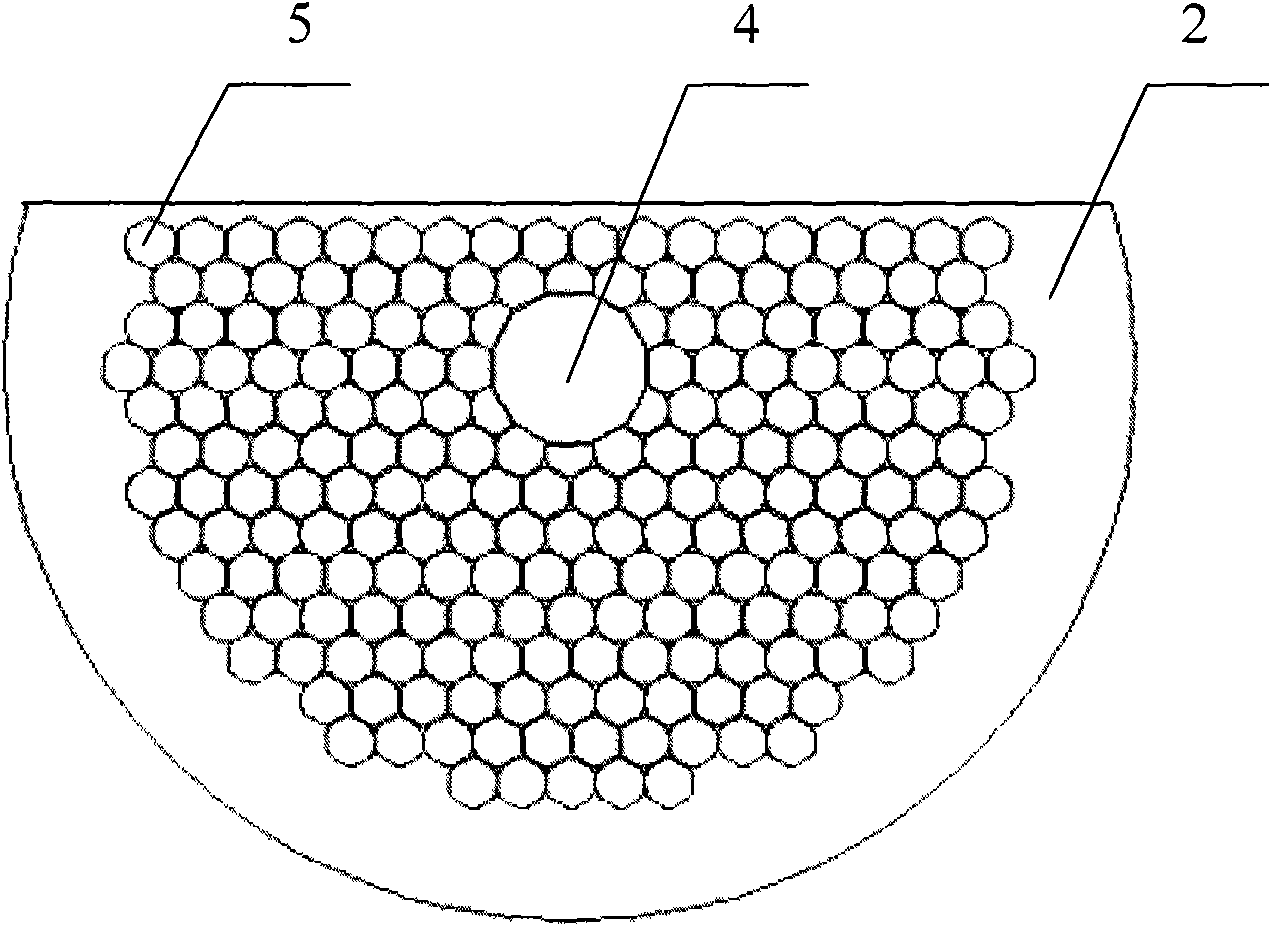

[0016] figure 2 It is a cross-sectional view of the polished part of the photonic crystal fiber. Photonic crystal fiber 1 is composed of core air holes 4 and cladding air holes 5 arranged periodically. In this embodiment, the length of the polished part 2 of the photonic crystal fiber is 4.5 cm, and the grinding depth is 50 μm.

[0017] The key technology for realizing the polarizing function in the present invention is:

[0018] Photonic crystal fiber is a new type of optical fiber. The core is made of pure silica, and the cladding is distributed with wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com